Description

Technical Specifications (For Spare Parts Verification)

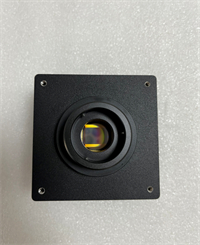

- Product Model: 18-10812.5

- Manufacturer: Typically an OEM optics supplier (e.g., Kowa, Computar, or Tamron under private label)

- System Compatibility: Designed for legacy industrial smart cameras with C-mount or proprietary lens interface (commonly Cognex In-Sight 5000/7000 series or Keyence CV-X)

- Focal Length Range: 18–108 mm (6× optical zoom)

- Aperture: Typically f/1.4–f/16 (manual or DC-iris)

- Mount Type: C-mount (1″–32 UN)

- Focus Mechanism: Manual or motorized (depends on system integration)

- Image Circle: ≥11 mm (compatible with 2/3″ or 1″ sensors)

- Operating Temperature: 0°C to +50°C

- Special Features: May include locking screws for zoom/focus, anti-vibration set screws, and IR correction coating

System Role and Downtime Impact

The 18-10812.5 zoom lens is typically installed on high-value automated inspection stations where product variants require different magnifications—such as PCB solder joint verification, bottle label alignment, or automotive component measurement. It is not a passive component; its precise optical alignment and repeatability are calibrated into the vision system’s measurement algorithms.

If the lens fails (e.g., zoom motor stalls, internal element decentering, or focus drift), the vision system cannot maintain measurement accuracy across product SKUs. This often forces the line into manual inspection mode or triggers false rejects, leading to reduced throughput and potential quality escapes. In regulated industries (e.g., medical device manufacturing), such a failure may constitute a reportable deviation, requiring full re-validation upon repair.

Reliability Analysis and Common Failure Modes

These lenses were engineered for industrial duty but contain mechanical and optical elements subject to long-term wear:

Common failure modes include zoom/focus gear stripping due to repeated actuation over years of operation, lubricant drying causing stiff movement or motor overload, and internal dust ingress leading to image artifacts (especially in non-sealed variants). In motorized versions, flex cable fatigue between moving lens groups can result in intermittent signal loss to position sensors.

A key design vulnerability is the reliance on mechanical set screws to lock zoom and focus positions. Vibration from nearby machinery can loosen these screws over time, causing focal shift during operation—a subtle but critical failure that may go undetected until yield drops.

For preventive maintenance, technicians should:

- Perform quarterly visual inspection for dust on front/rear elements

- Verify zoom/focus repeatability using a fixed test target

- Re-torque locking screws per OEM torque specs (typically 3–5 in-lb)

- Store spare lenses in climate-controlled, desiccated containers to prevent fungus growth on coatings

ZOOM LENS 18-10812.5

Lifecycle Status and Migration Strategy

The 18-10812.5 lens has been out of production for over 8–10 years. Original suppliers no longer offer replacements, and secondary-market units are often untested or degraded. Continuing to operate systems dependent on this lens carries escalating risk of unplanned downtime.

As a temporary measure, facilities may:

- Source used lenses from decommissioned lines and validate optical performance via MTF testing

- Retrofit with modern C-mount zoom lenses of similar focal range (e.g., Kowa LM18M108R), though this requires re-calibration of all vision tools and may need adapter rings

The strategic migration path is to upgrade the entire vision system to a current-generation platform (e.g., Cognex In-Sight 7000, Keyence CV-X300) that supports modern, readily available optics with better resolution, lighting integration, and software features. While this involves re-engineering inspection logic and fixturing, it eliminates single-point obsolescence and provides access to AI-based defect detection, remote diagnostics, and cybersecurity compliance—critical for future-proofing quality infrastructure.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: