Description

Technical Specifications (For Spare Parts Verification)

- Product Model: CP-9200SH-SVA

- Manufacturer: Yaskawa Electric Corporation

- System Compatibility: Yaskawa MP920 / MP930 platform

- CPU Type: SH-2 RISC processor (Hitachi architecture)

- Memory: Onboard SRAM (typically 128 KB–512 KB, battery-backed)

- Motion Capacity: Supports up to 8 axes of coordinated motion (via SVB/SVC modules)

- Communication Ports: RS-232 (programming), RS-422 (SV network for I/O and servo), optional Ethernet (via add-on module)

- Programming Software: MotionWorks (MWWorks) or MP920 Support Tool (Windows XP-era)

- Power Supply: 24 VDC, typically supplied via backplane

- Mounting: DIN-rail mountable CPU module

- Diagnostic Indicators: RUN, ERR, COMM, and axis status LEDs

System Role and Downtime Impact

The CP-9200SH-SVA serves as the central brain of Yaskawa MP920-based machines—commonly found in high-speed packaging lines, labelers, web handling systems, and converting equipment. It simultaneously runs ladder logic for discrete control and executes synchronized motion profiles for servos (e.g., flying cutters, indexing turrets). Because logic and motion are tightly integrated, a CPU failure results in an immediate and complete machine stop, often without graceful shutdown. In continuous-production environments like food & beverage or pharmaceutical packaging, this can cause line-wide downtime costing tens of thousands of dollars per hour, along with potential product waste due to mid-cycle interruption.

Reliability Analysis and Common Failure Modes

Many CP-9200SH-SVA units have operated reliably for 15–25 years, but aging introduces critical vulnerabilities. The most prevalent failure mode is loss of program or parameter data due to CMOS battery depletion—the onboard SRAM is volatile and relies on a replaceable lithium battery (typically BR2330 or equivalent). If the battery voltage drops below threshold, the entire application is erased upon power cycle. Secondary issues include:

- Corrosion or cold solder joints on the PCB caused by thermal cycling and humidity

- RS-422 transceiver failure on the SV bus, disrupting communication with servo drives and I/O modules

- Firmware corruption from power surges or EMI in electrically noisy plants

A key design weakness is the lack of non-volatile flash memory for program storage—unlike modern controllers, it cannot retain code without battery backup. Additionally, the reliance on legacy Windows XP-era software complicates recovery even when hardware is functional.

Recommended preventive actions:

- Replace the backup battery every 3–5 years, regardless of voltage reading

- Maintain offline backups of the MWWorks project file and compiled binary

- Perform annual continuity checks on SV bus cabling and terminal blocks

- Keep at least one tested spare CPU with identical firmware revision

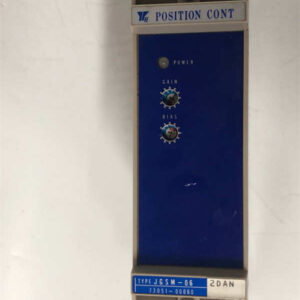

YASKAWA CP-9200SH-SVA

Lifecycle Status and Migration Strategy

Yaskawa has fully discontinued the MP920 platform. No new CP-9200SH-SVA units are available, and official repair services are no longer offered. Continued use carries high risk: spare scarcity, escalating costs, and inability to restore systems due to software obsolescence (e.g., MWWorks does not run reliably on modern Windows).

As a temporary measure, facilities may source refurbished CPUs—but long-term reliability is unverifiable.

Yaskawa’s official migration path is to upgrade to the MP3000iec or MP5000 series, which offer:

- Full IEC 61131-3 programming (via MotionWorks IEC)

- Integrated safety (optional)

- Native EtherCAT motion networking

- Backward-compatible function block libraries to ease logic conversion

The migration requires:

- Replacement of CPU, power supply, and I/O/servo modules

- Rewiring of field connections (new terminal layouts)

- Re-engineering of motion sequences using modern kinematic tools

- Recommissioning and performance validation

Organizations should initiate migration planning now, especially for safety-critical or high-availability lines, to avoid unplanned obsolescence-driven outages in the near future.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: