Description

Key Technical Specifications (For Spare Part Verification)

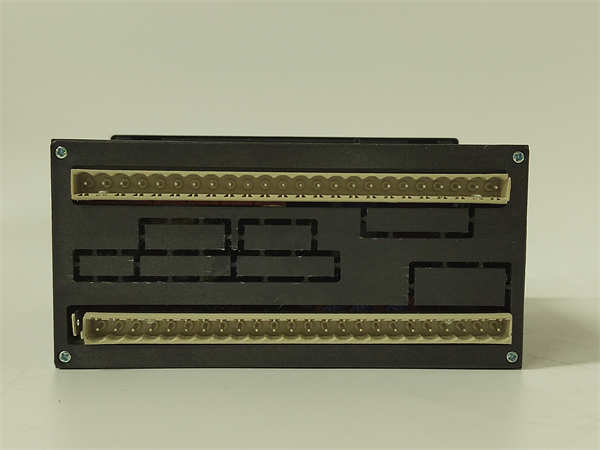

- Product Model: 8440-1713

- Manufacturer: WOODWARD, Inc.

- System Family: WOODWARD 8440 Series (Legacy Turbine Control Platform)

- Input Voltage: 24 VDC nominal

- Operating Temperature Range: 0°C to 60°C

- Communication Interfaces: Analog I/O, discrete signals; no native Ethernet

- Mounting Type: DIN rail or panel mount

- Firmware Version: Fixed (non-upgradable in field)

- Physical Dimensions: Approx. 240 mm x 160 mm x 90 mm

- Connector Types: Screw-terminal blocks, MIL-style connectors for sensors

System Role and Downtime Impact

The WOODWARD 8440-1713 serves as the core speed and load controller in older industrial turbine and engine-driven applications, commonly found in power generation, oil & gas, and marine propulsion systems. It directly interfaces with actuators, speed sensors, and generator breakers. Failure of this module typically results in an uncontrolled trip or inability to synchronize the unit to the grid, leading to a complete loss of mechanical drive or electrical output. In critical infrastructure—such as remote power plants or offshore platforms—this can trigger facility-wide operational disruption, safety interlocks, and extended downtime due to the difficulty in sourcing replacements.

Reliability Analysis and Common Failure Modes

Despite its age, many 8440-1713 units remain in service due to robust initial design and stable operating environments. However, aging components present increasing reliability risks. The most frequent failure modes include electrolytic capacitor degradation on internal power supply boards, leading to voltage instability or boot failures. Battery-backed RAM modules (used for configuration retention) often suffer from data corruption after 10–15 years, especially if backup batteries were not proactively replaced. Additionally, analog input circuits are susceptible to damage from ground loops or transient voltage spikes, particularly in harsh industrial settings without adequate signal conditioning.

Design weaknesses include reliance on non-replaceable surface-mount components and lack of diagnostic LEDs or self-test routines, making fault isolation difficult. Preventive maintenance should focus on: (1) annual inspection and replacement of onboard backup batteries; (2) thermal imaging of terminal blocks to detect loose connections; (3) cleaning of ventilation slots to prevent heat buildup; and (4) verifying sensor signal integrity to avoid false trips caused by degraded input signals.

WOODWARD 8440-1713

Lifecycle Status and Migration Strategy

WOODWARD officially discontinued the 8440 series, including model 8440-1713, with no direct drop-in replacement. Continued use carries significant risk: spare parts are scarce, technical support is limited, and repair services are restricted to third-party specialists. Long-term operation is not sustainable without a migration plan.

As a temporary measure, facilities may stockpile tested surplus units or engage in board-level repairs through specialized vendors. However, these approaches only delay inevitable obsolescence.

WOODWARD recommends migrating to the MicroNet™ Plus or SLC (System Logic Controller) platforms for equivalent or enhanced functionality. This transition typically requires re-engineering the I/O interface, updating control logic, and re-commissioning the entire control loop. While capital-intensive, such upgrades improve cybersecurity posture, enable remote monitoring via Modbus TCP or OPC UA, and extend system life by 15+ years. Early planning—including functional gap analysis and pilot testing—is essential to minimize transition risk.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: