Description

Key Technical Specifications (For Spare Parts Verification)

- Product Model: 8237-1246

- Manufacturer: Woodward, Inc.

- System Platform: NetCon 5000 Distributed Control System

- Module Type: Digital Input (DI), 16 channels

- Input Voltage Range: 18–32 V DC (nominal 24 V DC)

- Input Configuration: Sinking or sourcing (field-wiring dependent)

- Isolation: Group isolation (typically two groups of 8 channels) via optocouplers

- Response Time: ≤ 5 ms per channel

- Diagnostics: Per-channel LED indicators, module OK status, open-circuit detection

- Mounting: DIN rail-mounted in NetCon 5000 I/O carrier/baseplate

System Role and Downtime Impact

The 8237-1246 serves as a primary data acquisition interface in NetCon 5000 systems, commonly deployed in gas turbines, steam turbines, and engine-driven generator sets. It digitizes critical discrete signals from field devices—including generator breaker positions, lube oil pump run status, vibration alarm contacts, and fuel valve limit switches. Loss of this module results in up to 16 inputs being marked “bad” or forced in the control logic, potentially causing missed permissives during startup, false alarms, or undetected fault conditions that escalate into unplanned trips. Since redundancy is rarely implemented at the individual DI module level for auxiliary systems, failure typically necessitates a controlled or forced outage for replacement, followed by loop validation and logic requalification—processes significantly delayed by spare parts scarcity.

Reliability Analysis and Common Failure Modes

Despite its robust original design, the 8237-1246 is now vulnerable due to its typical deployment era (early-to-mid 2000s). The most prevalent failure mechanisms include degradation of optocouplers, which leads to signal dropout or “stuck” input states—especially under sustained high ambient temperatures or electrical stress. Electrolytic capacitors in internal power regulation circuits often dry out over time, causing intermittent resets or unstable operation. Terminal blocks may develop high-resistance connections due to corrosion or thermal cycling, mimicking open circuits in the field wiring. Additionally, repeated insertion cycles or vibration can wear backplane connectors, resulting in intermittent communication with the controller. A design limitation is the lack of per-channel fusing; a short on one input can affect an entire group of eight channels. Preventive maintenance should focus on periodic wet-loop testing during scheduled outages, visual inspection for capacitor bulging or burnt components, verification of terminal tightness, and monitoring of I/O quality flags in historical logs for early signs of degradation.

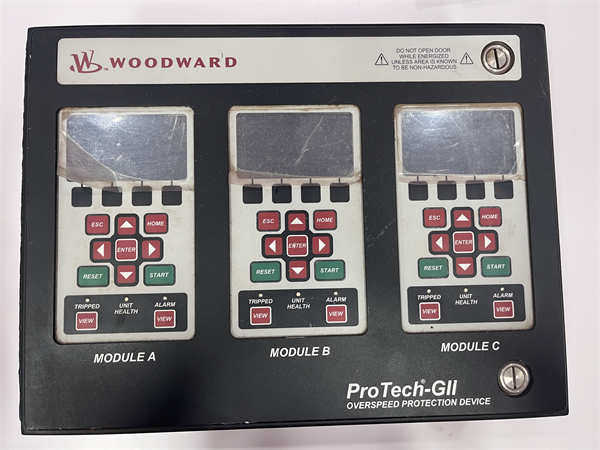

WOODWARD 8237-1246

Lifecycle Status and Migration Strategy

Woodward has formally discontinued the 8237-1246 as part of the broader obsolescence of the NetCon 5000 platform, with no official production or long-term support commitments. Continued operation carries substantial risk: untested surplus modules may fail prematurely, counterfeit units may lack proper isolation ratings, and diagnostic compatibility with current NetCon software versions cannot be guaranteed. In the short term, facilities should source only from certified vendors providing full functional test reports—including wet-loop validation at 24 V DC—and implement pre-installation burn-in procedures. Maintaining a small inventory of verified spares for mission-critical applications is advisable. The strategic long-term path is migration to modern Woodward platforms such as MicroNet Plus or MAX 300, which offer higher-density digital input modules (e.g., 9907-1620 series) with enhanced diagnostics, cybersecurity features, and support for contemporary engineering tools. While migration requires re-engineering of I/O assignments and logic validation, it eliminates dependency on obsolete hardware, restores access to vendor support, and ensures compliance with evolving operational and regulatory standards for critical power assets.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: