Description

Key Technical Specifications (For Spare Part Verification)

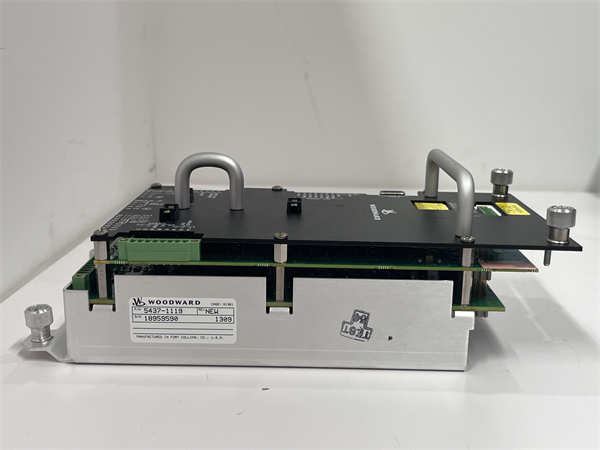

- Product Model: 5437-1119

- Manufacturer: WOODWARD

- Product Family: Synchronizer and Load Controller (SLC) for 2301A/EGT platforms

- Primary Function: Compares generator and bus voltage/frequency, issues raise/lower speed/load signals to governor, and closes breaker at sync point

- Input Signals:

- Generator PT (Potential Transformer) – typically 120 V AC

- Bus (Grid) PT – 120 V AC

- Generator CT (for kW/kVAR feedback, optional)

- Output Signals:

- 4–20 mA or contact closures to speed/load control inputs on governor

- Sync check relay output to breaker close circuit

- Communication: Standalone analog/digital interface; no digital bus (e.g., Modbus) on base model

- Power Supply: 24 V DC or 120 V AC (field-configurable via internal jumpers)

- Mounting: DIN rail or panel mount in control enclosure

- Diagnostic Indicators: LEDs for “In Sync,” “Speed Adjust,” “Voltage Match,” and fault conditions

- Compatibility: Designed for use with 2301A, EGT, PGA, or UG actuator-based systems; not compatible with newer MicroNet or SLC II platforms without adapter logic

System Role and Downtime Impact

The 5437-1119 is a critical enabler of automated generator operation in small hydro, cogeneration, and diesel power plants. It eliminates manual synchronization—a complex and error-prone task—by automatically matching voltage, frequency, and phase angle before closing the main breaker. In multi-unit plants, it also enables proportional load sharing based on kW or droop settings. If this module fails, operators must revert to manual synchronization using synchroscopes and voltmeters, significantly increasing startup time and risk of out-of-phase closure (which can damage generators or transformers). In unattended or remote sites, failure may result in complete loss of dispatch capability, especially during black-start or islanded scenarios.

Reliability Analysis and Common Failure Modes

The 5437-1119 combines analog signal conditioning with discrete logic, making it vulnerable to component aging. The most common failure modes include:

- Drift in voltage/frequency comparison circuits due to aging op-amps or reference ICs, causing inaccurate sync windows

- Failure of output driver transistors or relays, preventing speed/load commands from reaching the governor

- Degradation of electrolytic capacitors in power supply or filter stages, leading to unstable operation or reset loops

- Corrosion on terminal blocks or internal jumpers, especially in high-humidity environments, causing intermittent signal loss

Environmental stressors such as temperature cycling, dust, and electrical transients accelerate these issues. Recommended preventive actions include annual functional testing using a sync simulator, visual inspection for capacitor leakage or PCB discoloration, verification of clean and tight PT/CT wiring, and ensuring stable, filtered power supply to the module.

WOODWARD 5437-1119

Lifecycle Status and Migration Strategy

Woodward has discontinued the 5437-1119 as part of its transition to digital control platforms like MicroNet™ and SLC II. No new units are available, and Woodward no longer provides repair services, calibration support, or replacement documentation for this legacy module. Continued reliance poses significant operational risk, as secondary-market units are scarce and often untested.

Short-term mitigation includes:

- Maintaining a bench-tested spare with documented performance

- Implementing manual sync procedures with operator training

Long-term, migration to Woodward SLC II (e.g., 8440-1120) or integration into a MicroNet Plus system is recommended. These modern platforms offer:

- IEC 61850 communication

- Touchscreen HMI and remote access

- Advanced islanding detection and load management

- Built-in diagnostics and event recording

Migration requires replacing the SLC module, updating governor interface wiring, and re-commissioning sync parameters—but eliminates obsolescence exposure and enhances plant automation, safety, and compliance with modern grid codes (e.g., IEEE 1547).

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: