Description

Technical Specifications (For Spare Parts Verification)

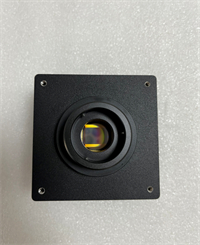

- Product Model: 03ZSTL6-00-201-RS

- Manufacturer: WINGREEN (supplied to GE for Mark VIe HI systems)

- System Family: GE SPEEDTRONIC™ Mark VIe High Integrity (HI) platform

- Compatible I/O Modules: IS230MDOIH1C, IS230MDOIH2C (Mark VIe HI digital output cards)

- Channel Count: 16 channels (matches 16-channel HI output modules)

- Output Type Interface: Relay dry-contact or 24 VDC wet-contact wiring points

- Terminal Type: Spring-clamp terminals with finger-safe protection

- Shielding: Dedicated shield bus bar with chassis ground connection

- Mounting: Inserts into standard Mark VIe HI I/O chassis (e.g., IC698CHS017-HI)

- Operating Voltage Rating: Up to 250 VAC / 30 VDC per channel

- Safety Compliance: Designed for IEC 61508 SIL3 applications in TMR architecture

System Role and Downtime Impact

The WINGREEN 03ZSTL6-00-201-RS is a passive but mission-critical component in GE Mark VIe High Integrity (HI) control systems deployed on heavy-duty gas turbines. It serves as the physical termination point between the HI digital output module and field devices such as fuel shutoff solenoids, lube oil dump valves, and generator trip coils. While it contains no active electronics, its mechanical and electrical integrity directly determines whether a safety command can be executed. A degraded terminal—due to corrosion, loose connections, or insulation breakdown—can result in high contact resistance, open circuits, or unintended grounding. In worst-case scenarios, this may cause a failure to trip during an over-temperature or overspeed event, risking catastrophic equipment damage or safety incidents. Even partial degradation can lead to nuisance trips due to intermittent signal loss, causing unplanned outages and lost revenue.

Reliability Analysis and Common Failure Modes

Despite being a passive board, the 03ZSTL6-00-201-RS is exposed to harsh operational stresses. Common failure mechanisms include:

- Terminal oxidation: Moisture, hydrogen sulfide, or salt air in turbine enclosures corrodes copper contacts, increasing resistance and generating heat under load.

- Spring-clamp fatigue: Repeated thermal cycling and vibration weaken clamping force, leading to intermittent connections that mimic output module faults.

- Insulation tracking: Dust combined with humidity can create conductive paths between adjacent terminals, especially at higher voltages, causing cross-channel leakage or short circuits.

- Shield bus disconnection: Poor grounding of the shield terminal introduces noise into adjacent analog circuits or causes false diagnostics in the HI system.

A key vulnerability is the lack of self-monitoring—unlike active I/O modules, terminal boards provide no diagnostic feedback. As preventive maintenance, operators should:

- Perform infrared thermography during loaded operation to detect hot spots at terminals

- Measure contact resistance annually using low-resistance ohmmeters (<10 mΩ acceptable)

- Verify torque on all terminal screws per GE specifications (typically 0.5–0.6 N·m)

- Replace boards showing discoloration, pitting, or physical deformation immediately

WINGREEN 03ZSTL6-00-201-RS

Lifecycle Status and Migration Strategy

WINGREEN ceased production of the 03ZSTL6-00-201-RS following GE’s supply chain rationalization. GE no longer lists this part in its catalog, and new units are unavailable through authorized distributors. Continued use depends entirely on surplus inventory, with significant risk of receiving non-RS revisions (e.g., standard instead of HI-rated) that lack proper spacing or shielding for safety applications.

As a temporary mitigation, facilities should:

- Source only from vendors who validate compatibility with IS230MDOIxxx HI modules via pinout and dielectric testing

- Maintain a minimum of two verified spares per turbine control panel

- Pre-test all replacements on a bench-mounted HI output module before installation

Long-term, the only sustainable solution is migration to Mark VIeS or Advanced Controls Platform (ACP), which integrate diagnostics and conformal coating into modern terminal designs. Until then, rigorous inspection and proactive replacement of aging terminal boards remain essential to ensure the final link in the safety chain remains intact.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: