Description

Key Technical Specifications (For Spare Parts Verification)

- Product Model: 03ZSTJ3-00-105

- Manufacturer: Wingreen (acquired by Parker Hannifin in early 2000s)

- System Family: Industrial hydraulic power units and manifold blocks

- Valve Type: Proportional, pressure-compensated 2-way flow control

- Mounting: Screw-in cartridge, cavity per ISO 4401-03 / NFPA D03

- Flow Rating: Approximately 10–15 L/min (based on suffix “105”)

- Control Signal: Typically ±10 VDC or 4–20 mA (depends on integrated amplifier, if any)

- Pressure Rating: Up to 210 bar (3000 psi) working pressure

- Sealing: Nitrile (NBR) standard; optional FKM for high-temp applications

- Spool Configuration: Normally closed (flow blocked at zero signal)

System Role and Downtime Impact

The Wingreen 03ZSTJ3-00-105 is typically embedded in a custom hydraulic manifold that controls the advance or return speed of a critical actuator—such as the ram in a metal stamping press or the injection unit in a plastic molding machine. As a proportional flow control valve, it enables smooth, repeatable motion profiles by regulating flow independent of load pressure variations. Its pressure-compensating feature ensures consistent speed even as system pressure fluctuates.

If this valve fails—due to coil burnout, spool seizure, or internal leakage—the affected axis loses controlled motion. In a press application, this may manifest as erratic ram speed, incomplete forming cycles, or, in worst cases, uncontrolled descent. Most machines will fault out or require emergency stop activation, resulting in unplanned downtime. Because the valve is often installed deep within a manifold block, replacement requires system depressurization, oil drainage, and mechanical disassembly—extending repair time to several hours or more.

Reliability Analysis and Common Failure Modes

Despite robust construction, the 03ZSTJ3-00-105 is prone to several age- and environment-related failure mechanisms:

- Coil insulation breakdown: Continuous exposure to heat from adjacent valves or ambient sources degrades enameled wire insulation, leading to short circuits or open windings. Moisture ingress through connector seals accelerates this process.

- Spool sticking: Contamination from degraded hydraulic fluid (e.g., varnish, water, particulates) causes the precision-machined spool to bind in the sleeve, resulting in sluggish response or complete lock-up.

- Internal leakage due to wear: Over years of operation, the metering edges erode, causing flow drift and loss of speed accuracy—often mistaken for pump or accumulator issues.

A key vulnerability is the lack of standardized amplifier interface; many installations used proprietary or third-party drivers, making signal compatibility difficult to verify during replacement. Preventive maintenance should focus on:

- Monitoring hydraulic fluid cleanliness (target ISO 4406 ≤ 18/16/13)

- Inspecting electrical connectors for corrosion or oil wicking

- Performing periodic functional tests (e.g., step response via HMI or PLC)

- Replacing filter elements upstream of the manifold regularly

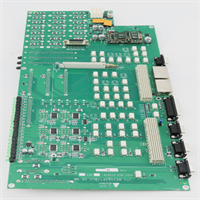

WINGREEN 03ZSTJ3-00-105

Lifecycle Status and Migration Strategy

Wingreen as a brand was absorbed into Parker Hannifin’s extensive cartridge valve portfolio in the early 2000s, and the 03ZSTJ3 series has since been discontinued without a direct 1:1 replacement. Parker does not officially support cross-referencing this model, though engineering teams have successfully substituted equivalent valves from the Parker PVE or D1VW proportional families—provided cavity dimensions, flow characteristics, and electrical interface are validated.

Continued use carries significant risk: no new production exists, and surplus units vary widely in condition. Many lack original packaging or test certificates, increasing the chance of installing a degraded or counterfeit part.

Interim mitigation strategies include:

- Sourcing multiple tested spares from reputable industrial surplus vendors

- Implementing oil analysis programs to extend component life

- Retrofitting with modern valves in non-critical axes to build experience

For long-term reliability, a full hydraulic manifold redesign using current Parker proportional cartridges (e.g., PVE-*-OC-M)**) is recommended. This allows integration of digital diagnostics, improved efficiency, and access to global support. While requiring upfront engineering effort, it eliminates dependency on an obsolete, unsupported component in safety- or quality-critical processes.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: