Description

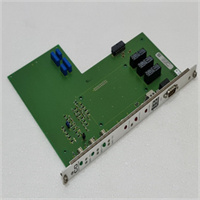

Key Technical Specifications (For Spare Parts Verification)

- Product Model: 03ZSTI7-00-402-RS

- Manufacturer: WINGREEN

- System Family: Modular DIN-rail I/O series for industrial automation

- Input Channels: 4 isolated analog inputs

- Supported Sensor Types: Likely Pt100 RTD or Type K/J thermocouples (common for “-402” suffix variants)

- Input Range: Typical RTD range 0–100°C or -50–+200°C; thermocouple range per type

- Output Signal: Digital or scaled analog (e.g., 0–10 V, 4–20 mA) — often designed to interface with PLC analog inputs

- Power Supply: 24 VDC (standard for DIN rail modules)

- Isolation: Channel-to-channel and input-to-power isolation (typically 500 VAC or higher)

- Mounting: 35 mm DIN rail

- Dimensions: Approx. 22.5–35 mm width (2–3 module spaces)

- Indicators: Per-channel LED status (if equipped)

System Role and Downtime Impact

The 03ZSTI7-00-402-RS functions as a signal conditioner and interface between temperature sensors (e.g., in ovens, chillers, extruders, or reactors) and the central controller. It converts raw sensor resistance or millivolt signals into standardized outputs usable by older PLCs lacking native high-accuracy temperature inputs. In processes requiring tight thermal control—such as food sterilization, plastic molding, or chemical batch reactions—a failure can cause inaccurate readings, leading to product spoilage, safety interlocks, or unplanned downtime. Because temperature is often a critical process parameter, loss of even one channel may force a full line halt depending on system logic.

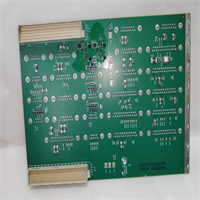

Reliability Analysis and Common Failure Modes

These modules are prone to drift and failure due to aging components in the analog front-end circuitry. Common issues include:

- Drift in cold-junction compensation circuits (for thermocouple versions), causing offset errors

- Degradation of precision resistors or reference voltages, leading to non-linear scaling

- Moisture ingress or contamination on terminal blocks, increasing noise or causing open circuits

- Failure of onboard voltage regulators due to sustained overvoltage or heat stress

A design vulnerability is the lack of robust ESD protection on sensor terminals—common in cost-optimized modules of this era—making them susceptible to damage during maintenance or from nearby inductive loads. Additionally, the absence of diagnostic features (e.g., sensor break detection) means failures may go unnoticed until process anomalies occur.

Preventive actions include: periodic calibration against known references, visual inspection for burnt components or swollen capacitors, cleaning terminal blocks, and verifying wiring integrity—especially shield grounding for thermocouple leads.

Preventive actions include: periodic calibration against known references, visual inspection for burnt components or swollen capacitors, cleaning terminal blocks, and verifying wiring integrity—especially shield grounding for thermocouple leads.

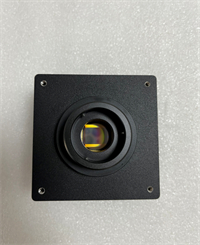

WINGREEN 03ZSTI7-00-402-RS

Lifecycle Status and Migration Strategy

WINGREEN has not maintained public documentation or distribution for the 03ZSTI7 series in recent years. The brand appears inactive in mainstream industrial automation channels, suggesting discontinuation without formal migration guidance. Genuine replacements are unavailable through authorized networks, forcing reliance on unverified surplus stock with uncertain reliability.

As an interim solution, functionally equivalent modules from reputable manufacturers can be substituted—for example:

As an interim solution, functionally equivalent modules from reputable manufacturers can be substituted—for example:

- Phoenix Contact AXC F 1151 (for RTD) or AXC F 1152 (thermocouple)

- Weidmüller ACT20C series

- Omron ZW-RA04-T (for compact retrofit)

These require matching input types, output ranges, and physical dimensions, but typically offer better diagnostics and long-term support. For comprehensive modernization, integrating native high-density temperature I/O into a current-generation PLC platform (e.g., Siemens SM 622, Allen-Bradley 1756-IRT8) eliminates dependency on external conditioners. Until then, maintaining calibrated spares and implementing redundant temperature monitoring where feasible mitigates operational risk.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: