Description

Key Technical Specifications (For Spare Parts Verification)

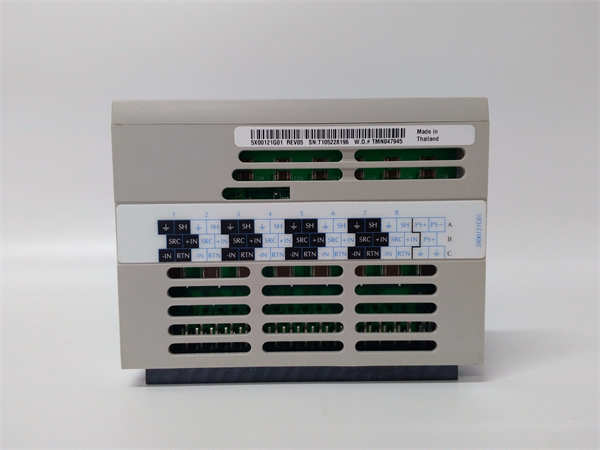

- Product Model: 5X00121G01

- Manufacturer: Westinghouse Electric Corporation

- System Platform: OVATION Distributed Control System (early generations, pre-Emerson rebranding)

- Form Factor: Proprietary PCB, typically installed in industrial PC-based OVATION workstations

- Function: Likely video graphics controller, serial/parallel I/O, or bus interface card (exact function varies by system revision)

- Connectors: May include VGA, RS-232/485, or proprietary backplane interfaces

- Power Requirements: +5 VDC / +12 VDC via workstation motherboard or backplane

- Compatibility: Specific to OVATION workstation models with matching BIOS/firmware revisions

- Markings: Silkscreen includes “5X00121G01”, revision letter (e.g., “Rev A”), and Westinghouse logo

System Role and Downtime Impact

The 5X00121G01 is typically embedded within an OVATION Operator Workstation—a critical human-machine interface (HMI) node that allows plant personnel to monitor processes, acknowledge alarms, and issue manual commands. If this board fails (e.g., due to video chip degradation or I/O controller malfunction), the workstation may exhibit a blank screen, frozen display, or complete boot failure. In facilities where only one or two engineering stations exist, such a failure can prevent access to configuration tools, alarm history, or real-time trending—severely limiting operational response during abnormal conditions. While the underlying DCS controllers may continue running, the loss of situational awareness significantly increases the risk of misdiagnosis or delayed intervention during process upsets.

Reliability Analysis and Common Failure Modes

Given its age (likely 20–30 years in service), the 5X00121G01 is highly susceptible to component-level aging, especially since it resides in continuously powered industrial PCs with limited cooling.

Common failure modes include:

- Electrolytic capacitor degradation: Onboard power-filtering capacitors dry out, causing voltage instability and intermittent crashes or failure to initialize.

- Solder joint fatigue: Thermal cycling leads to micro-cracks in through-hole or surface-mount joints, particularly around high-power components like video DACs or bus drivers.

- EEPROM or firmware corruption: Battery-backed configuration memory may lose data if the CMOS battery fails, rendering the board unrecognized by the host system.

- Connector or edge-finger corrosion: Oxidation on ISA/PCI or proprietary backplane contacts causes poor signal integrity.

Design weaknesses include:

- Use of consumer-grade capacitors not rated for long-term industrial operation;

- Lack of conformal coating, making the board vulnerable to humidity and airborne contaminants;

- Dependence on obsolete chipsets (e.g., early VGA or UART ICs) with no modern equivalents.

Preventive maintenance recommendations:

- Power-cycle workstations periodically to exercise components and detect early instability;

- Replace CMOS batteries proactively every 3–5 years;

- Inspect boards for bulging capacitors or white residue (electrolyte leakage);

- Maintain at least one fully functional spare workstation in cold standby.

Lifecycle Status and Migration Strategy

Emerson considers all Westinghouse-branded OVATION hardware obsolete. The 5X00121G01 has no official replacement, and Emerson no longer offers repair services for this generation of boards. Continued reliance on such components exposes sites to escalating downtime risk and potential regulatory scrutiny (e.g., under NERC CIP or ISO 55000 asset management standards).

Interim mitigation options include:

- Sourcing tested units from specialized industrial surplus vendors with full functional verification (including boot-to-OVATION test);

- Engaging third-party electronics repair firms for board-level rework (capacitor replacement, reballing, etc.);

- Virtualizing the OVATION workstation environment on modern hardware using emulation (though licensing and performance limitations apply).

Emerson’s strategic path is migration to the OVATION 4 platform, which runs on commercial off-the-shelf (COTS) servers and workstations with standard graphics cards. This transition involves:

- Rehosting the OVATION application on new hardware certified by Emerson;

- Upgrading to current OVATION software versions (e.g., v4.x);

- Retaining existing controllers and I/O while modernizing only the HMI layer (in many cases).

For sites not ready for full migration, maintaining a small inventory of verified spares—paired with rigorous workstation health monitoring—is the most pragmatic short-term approach. However, given the increasing fragility of these legacy boards, planning a phased workstation replacement should be prioritized in capital budgets.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: