Description

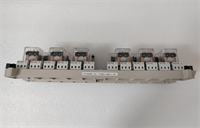

Key Technical Specifications (For Spare Part Verification)

- Product Model: 1C31166G02

- Manufacturer: Westinghouse Electric Corporation (automation division, now part of Emerson)

- System Family: OVATION Distributed Control System

- Module Type: Digital Output (DO) Module

- Output Channels: Typically 16 isolated dry-contact or wetted outputs (varies by backplane configuration)

- Output Type: Relay-driven or transistor-switched (depending on terminal base used)

- Voltage Rating: Compatible with 24–125 V DC/AC loads (via external relay packs)

- Isolation: Channel-to-channel and field-to-system isolation via optocouplers and relay barriers

- Backplane Interface: Proprietary OVATION I/O bus (connects to 1C31199 or similar carrier modules)

- Diagnostic Capability: Basic LED indicators per channel; fault reporting via OVATION workstation

- Mounting: DIN rail or chassis-mounted within I/O cabinet

- Firmware Dependency: None (hardware-only module), but requires correct I/O database mapping in OVATION Logic Studio

-

Westinghouse 1C31166G02

System Role and Downtime Impact

The 1C31166G02 is commonly deployed in fossil fuel, nuclear, or hydroelectric power plants to actuate critical final control elements—such as turbine trip solenoids, auxiliary pump starters, or damper actuators. It receives digital commands from the OVATION controller and energizes external relays to close or open high-power circuits. Because many of these outputs are tied to safety-related sequences (e.g., boiler purge, emergency shutdown), a failure of this module can result in:

- Inability to start/stop key equipment during transients,

- Loss of automatic protective actions, increasing risk of equipment damage,

- Forced manual operation or plant derating until repaired.

In non-redundant configurations—which were common in early OVATION deployments—the failure of a single 1C31166G02 can directly contribute to unplanned outages.

Reliability Analysis and Common Failure Modes

Although designed for industrial reliability, this module is now decades old in many installations, making it vulnerable to age-related degradation.

- Common Failure Modes:

- Relay coil burnout or contact welding due to repeated switching of inductive loads.

- Optocoupler degradation causing signal dropout or false “on” states.

- Corrosion or oxidation on edge connector fingers, leading to intermittent communication with the backplane.

- Design Weaknesses:

- Limited surge suppression on field terminals—susceptible to voltage spikes from unclamped solenoid coils.

- No onboard self-diagnostics beyond basic LEDs; troubleshooting often requires loop-back testing or substitution.

- Preive Maintenance Recommendations:

- Inspect all connected relay coils and ensure flyback diodes/snubbers are installed on inductive loads.

- Clean backplane connectors annually with contact enhancer spray to prevent high-resistance faults.

- Perform functional output tests during scheduled outages using OVATION’s built-in I/O forcing tools.

- Store spares in anti-static, humidity-controlled packaging to prevent PCB delamination or corrosion.

-

Westinghouse 1C31166G02

Lifecycle Status and Migration Strategy

Emerson no longer manufactures the 1C31166G02. The current standard digital output modules for OVATION include the 1C31166G05 (enhanced diagnostics, higher density) and 1C31237G01 (solid-state outputs). However, direct replacement may require changes to terminal bases, wiring, and software configuration.

- Interim Solutions:

- Source only from vendors who provide full channel-by-channel continuity and load-driving validation.

- Implement external monitoring (e.g., current sensors on output lines) to detect latent failures.

- Migration Path:

- Emerson supports in-place upgrades to newer DO modules with minimal rewiring if compatible terminal bases are used.

- Recommended steps:

- Audit all 1C31166G02 usage and consolidate low-utilization modules.

- Replace with 1C31166G05 modules during planned outages, updating the I/O database in Logic Studio.

- For high-criticality outputs, consider adding redundant output paths or hardwired backup logic.

- Until migration is complete, maintaining a minimum of two fully tested spares per control rack is essential for operational resilience.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: