Description

Technical Specifications (For Spare Parts Verification)

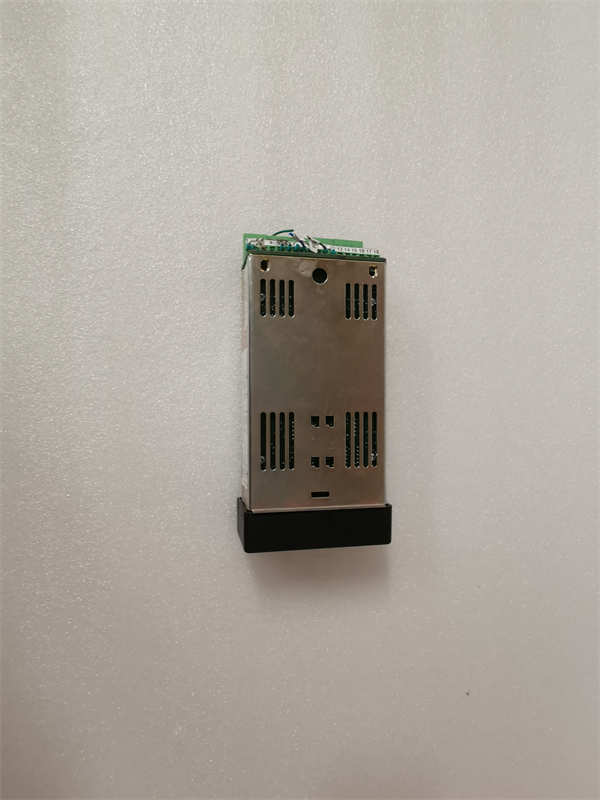

- Product Model: CLS208

- Manufacturer: Watlow Electric Manufacturing Co.

- Series: DIN-A-MITE® CLS (Compact Loop Series)

- Mounting Style: 1/16 DIN (48 x 48 mm panel cutout), snap-in or screw-mounted

- Input Types: J, K, T, E, N, R, S, B thermocouples; PT100 RTD (configurable via internal DIP switches)

- Output Options: SPST electromechanical relay (typically 5 A @ 240 VAC) or solid-state relay drive (for external SSR)

- Control Algorithm: On/Off or PID (adjustable via front-panel trim pots or internal jumpers)

- Power Supply: 100–240 VAC/VDC, 50/60 Hz (universal input)

- Display: None or basic LED status indicators (depending on sub-variant)

- Environmental Rating: Operating temperature 0°C to 55°C; non-condensing humidity

- Approvals: UL, CSA, CE (varies by production batch)

System Role and Downtime Impact

The CLS208 was widely deployed in the 1990s and early 2000s as a cost-effective temperature regulator in industrial heating applications—particularly in plastic injection molding, food processing, and small batch ovens. It typically controls a single heating zone by modulating power to a heater based on sensor feedback. While not part of a formal safety instrumented system (SIS), its failure can lead to significant operational consequences: an open-circuit fault may cause process under-temperature and scrap production, while a stuck-closed relay can result in overheating, material degradation, or activation of independent high-limit safety devices that halt the entire line. In unattended or batch processes, such failures may go undetected until quality audits or equipment damage occurs.

Reliability Analysis and Common Failure Modes

This controller is mechanically simple but prone to predictable wear due to its reliance on electromechanical components. The most frequent failure is relay contact welding or pitting, caused by repeated switching of inductive loads (e.g., contactors or heater elements) without adequate snubber circuits. A second common issue is input signal drift due to aging cold-junction compensation circuits, leading to inaccurate temperature readings—especially when used with long thermocouple runs in electrically noisy environments. Units installed in high-vibration panels may also suffer from loose internal jumper settings, altering control behavior unexpectedly. For preventive maintenance, technicians should: (1) inspect relay operation annually using a contact resistance test, (2) verify temperature accuracy against a calibrated reference probe, (3) ensure thermocouple extension wires are shielded and grounded at one end only, and (4) keep spares in original packaging to prevent potentiometer drift during storage.

WATLOW CLS208

Lifecycle Status and Migration Strategy

Watlow discontinued the CLS208 as part of its transition to digital, communications-enabled platforms like the E series and F4T controllers. No new units are available, and technical documentation is archived. Continuing to use the CLS208 exposes facilities to increasing spare parts scarcity and lack of calibration support. As an interim solution, verified used units can be sourced from industrial surplus suppliers—but must be functionally tested across full input/output ranges before deployment. The recommended upgrade path is the Watlow ELC/EVC series or F4T DIN rail controller, which offer universal inputs, configurable outputs (relay, SSR, analog), Modbus RTU communication, and auto-tuning PID—all in the same 1/16 DIN form factor. This allows drop-in replacement with minimal panel modification. However, migration requires reconfiguration of setpoints, tuning parameters, and potentially rewiring if switching from relay to SSR output. For multi-zone systems, consolidating several CLS208 units into a single multi-loop F4T can reduce long-term maintenance burden and enable remote monitoring—making it a compelling case for proactive replacement during planned outages.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: