Description

Key Technical Specifications (For Spare Part Verification)

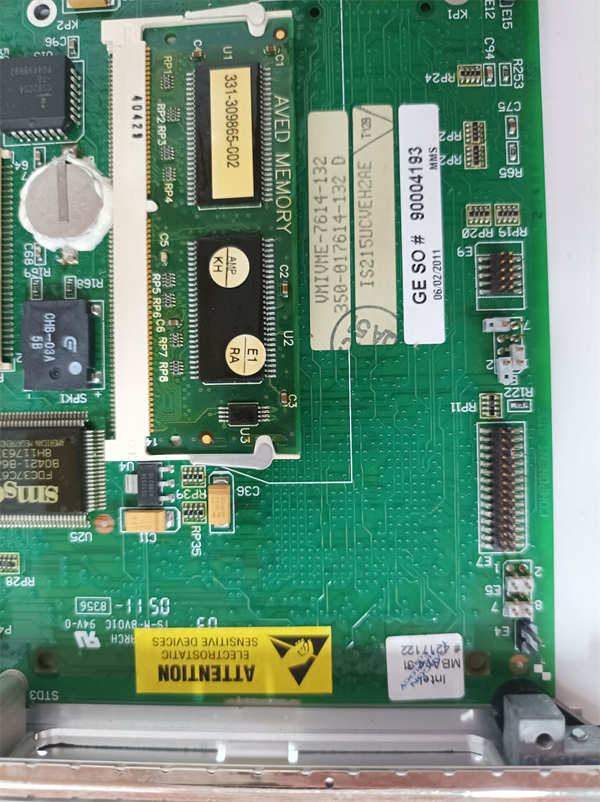

- Product Model: VMIVME-7614-132350-017614-132 / IS215UCVEH2AE

- Manufacturer: GE Power (formerly GE Intelligent Platforms, with hardware sourced from VMIC/VME Microsystems International Corporation)

- System Family: Mark VIe turbine control system (specifically for UCVE controller chassis)

- Input Channels: 16 single-ended or 8 differential analog inputs

- Input Range: ±10 V DC, programmable gain per channel

- Isolation: 500 V RMS channel-to-channel and channel-to-backplane

- Resolution: 16-bit A/D conversion

- Sampling Rate: Up to 100 kS/s aggregate

- Backplane Interface: VME64 (compatible with GE’s proprietary Mark VIe backplane protocol)

- Operating Temperature: 0°C to +60°C

- Firmware Dependency: Requires specific FPGA image version matching the UCVE controller’s software release (e.g., ToolboxST version)

System Role and Downtime Impact

The IS215UCVEH2AE (marketed as VMIVME-7614-132) is a foundational I/O module in GE’s Mark VIe distributed control architecture for gas and steam turbines. It digitizes critical analog signals—such as bearing temperature, exhaust thermocouples, lube oil pressure, and vibration probes—and delivers them to the UCVE (Universal Control and Voting Engine) for real-time protection logic execution.

Because Mark VIe employs triple-modular redundancy (TMR) for safety-critical functions, a single failed analog input card may not immediately trip the turbine—but it degrades system redundancy. If a second channel fails before replacement, the system may force a “soft trip” or enter a restricted operating mode. In non-redundant monitoring applications (e.g., auxiliary skids), a single card failure can cause complete loss of visibility on multiple parameters, increasing operational risk. Replacement delays directly extend exposure to unplanned outages.

Reliability Analysis and Common Failure Modes

Despite robust industrial design, this module exhibits age-related vulnerabilities after 10–15 years of continuous service in high-temperature turbine enclosures:

- A/D converter drift or channel dropout: Caused by thermal stress on precision analog components, leading to inaccurate readings or “bad value” flags in ToolboxST.

- Backplane connector corrosion: Vibration and humidity in power plant environments accelerate oxidation on VME edge fingers, causing intermittent communication or full channel loss.

- FPGA configuration corruption: Though flash-based, the onboard FPGA can lose its bitstream due to power cycling glitches or EMI, rendering the module unresponsive.

- Isolation barrier breakdown: Repeated voltage transients on field wiring can degrade opto-isolators, compromising safety isolation and risking ground loops.

Preventive maintenance recommendations:

- Perform annual calibration checks using a precision signal source to verify channel accuracy across full range.

- Inspect and clean VME connectors during scheduled outages; apply contact enhancer if oxidation is present.

- Monitor diagnostic logs in ToolboxST for “I/O module fault” or “channel invalid” events as early warning signs.

- Maintain at least one tested spare per turbine, stored in anti-static packaging with firmware verified against current system revision.

VMIVME-7614-132350-017614-132 D IS215UCVEH2AE GE

Lifecycle Status and Migration Strategy

GE has phased out the VMIVME-7614 series in favor of newer Mark VIeS (single-channel) and Mark VIe+ architectures based on open standards. The IS215UCVEH2AE is no longer produced, and official repair services are unavailable. Lead times for verified spares now exceed 12 weeks, with prices increasing 20–30% annually.

Interim risk mitigation includes:

- Sourcing only from vendors who provide full functional test reports and firmware version confirmation.

- Implementing board-level repair partnerships for capacitor replacement or re-flashing of corrupted FPGAs.

- Reducing thermal stress by ensuring adequate cabinet ventilation around I/O chassis.

Long-term, GE recommends migration to Mark VIe+, which uses Ethernet-based I/O (e.g., IS200/IS215+ series) and eliminates VME dependency. However, this requires full control system modernization. For facilities not ready for full upgrade, maintaining a strategic spare inventory—coupled with rigorous condition monitoring—is the only viable path to continued reliability. Delaying action increases the probability of forced outages due to unavailability of this mission-critical interface module.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: