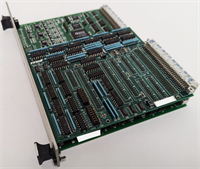

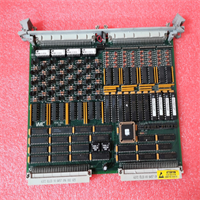

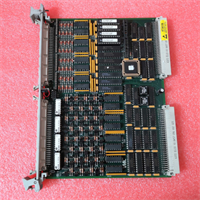

Description

Key Technical Specifications (For Spare Parts Verification)

- Product Model: VMIVME-2536

- Manufacturer: VMIC

- System Family: VME64 / VME64x embedded computing platform

- Board Type: Parallel digital input/output interface

- I/O Channels: 96 bits total, organized as six 16-bit ports (configurable per port as input or output)

- Signal Levels: TTL/CMOS compatible (0–5 V), non-isolated

- Data Transfer Mode: Programmed I/O, interrupt-driven, or block transfers via VME bus

- Bus Interface: VME64, 32-bit, A24/A32 addressing, D16/D32 data paths

- Form Factor: 6U VME (233.35 mm × 160 mm), single-slot

- Power Consumption: Typically <5 W (verify on unit label)

- Diagnostic Features: No built-in LEDs; status accessible only via software register reads

System Role and Downtime Impact

The VMIVME-2536 was widely deployed in military test systems, aerospace simulation rigs, industrial automation, and scientific instrumentation where high-density, low-latency digital I/O was required. It interfaces directly with custom hardware—such as stimulus/response units, encoder interfaces, relay drivers, or timing triggers—enabling real-time bit-level control and monitoring.

Because it often serves as the primary digital link between the VME-based controller and external hardware, a failure (e.g., shorted output, dead input buffer, or bus timeout) can render entire subsystems inoperable. In automated test environments (ATE), this may halt validation of critical components; in closed-loop control, it could cause loss of feedback or unsafe actuator states. Unlike modular PLC I/O, this board is typically hardwired into custom backplanes or breakout cables, making field bypass impractical. Recovery requires physical replacement and revalidation of I/O mapping—a process that can take days in regulated industries.

Reliability Analysis and Common Failure Modes

Although designed for industrial use, the VMIVME-2536 lacks isolation and modern protection circuits, making it vulnerable to field-induced damage. Common failure modes include:

- Output driver burnout: Driving inductive loads (e.g., relays) without flyback diodes causes voltage spikes that destroy TTL output buffers.

- Input latch-up: Exposure to overvoltage (>5.5 V) or ESD can permanently damage CMOS input stages.

- VME bus transceiver degradation: Aging 74ACT series or equivalent bus interface chips develop timing skew, leading to configuration space errors or DMA faults.

- PCB trace corrosion: In humid or contaminated environments, uncoated traces near edge connectors corrode, causing intermittent opens.

Design limitations include absence of optical isolation, no per-channel diagnostics, and reliance on software for direction control—increasing risk of misconfiguration damage.

Recommended preventive actions:

- Verify all field wiring includes clamping diodes and current limiting

- Use external opto-isolator modules for non-TTL signals

- Perform periodic continuity and leakage tests during scheduled outages

- Maintain spares in static-shielded, climate-controlled storage

- Document jumper settings and I/O mapping for rapid swap-out

VMIVME-2536 VMIC

Lifecycle Status and Migration Strategy

The VMIVME-2536 has been obsolete for well over a decade. VMIC was acquired by GE Fanuc, later divested to Emerson, and the product line was discontinued without a direct successor. No factory support, firmware updates, or new units exist. Remaining inventory is limited to surplus dealers, with authenticity and reliability unverified.

Continued use carries high operational risk, especially in safety- or mission-critical systems.

Short-term mitigation includes:

- Partnering with specialized embedded repair firms for component-level rework

- Implementing external signal conditioning to reduce board stress

- Creating functional test fixtures to validate spare units before storage

Long-term migration paths depend on system architecture:

- COTS VME replacements: Companies like Acromag, UEI, or WinSystems offer modern VME digital I/O boards with similar channel counts—but require software reintegration.

- PCIe or PXIe transition: For new chassis, migrate to reflective memory or FPGA-based I/O platforms with higher performance and support.

- Custom FPGA carrier: In high-value legacy systems, design a drop-in replacement using an FPGA to emulate the original register map while adding isolation and diagnostics.

Given the board’s role in tightly coupled systems, migration planning should include full I/O audit, signal integrity review, and regression testing. Proactive action is essential—waiting for failure risks extended downtime in increasingly unsupported environments.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: