Description

Key Technical Specifications (For Spare Part Verification)

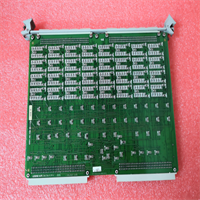

- Product Model: VMIVME-1128

- Manufacturer: VMIC (VME Microsystems International Corporation)

- Bus Interface: VME64 (6U form factor, P1/P2 connectors), compatible with 32-bit VMEbus (A24/D32)

- Memory Type: Static RAM (SRAM), non-volatile option not standard

- Capacity: 128 KB (organized as 64K x 16 bits)

- Access Time: Typically 25–55 ns (depending on speed grade)

- Ports: Two independent, fully asynchronous ports with separate address/data/control buses

- Interrupt Support: Onboard interrupt logic for port-to-port signaling (via VME IRQ lines)

- Address Mapping: Configurable via DIP switches or jumpers for base address and memory window

- Power: +5 V DC (primary), ±12 V (optional for interface buffers)

- Form Factor: Standard 6U VME card (233.35 mm × 160 mm)

- Compatibility: Works with Motorola 680×0, PowerPC, and Intel-based VME single-board computers (SBCs) from Force, DY4, Condor, etc.

System Role and Downtime Impact

The VMIVME-1128 was widely deployed in real-time embedded systems where deterministic inter-processor communication was critical—such as:

- Nuclear reactor protection systems (e.g., Westinghouse OCS)

- Military radar and sonar signal processors

- Power grid phasor measurement units (PMUs)

- Semiconductor test handlers

In these applications, one CPU might acquire sensor data while another performs control calculations, with the VMIVME-1128 acting as the shared “blackboard.” A failure (e.g., SRAM bit corruption, port lockup) causes data desynchronization, leading to logic errors, safety system faults, or complete application crash. Because VME systems often lack software-based redundancy for shared memory, this module represents a single point of failure with severe operational consequences.

Reliability Analysis and Common Failure Modes

Despite robust industrial design, the VMIVME-1128 is highly susceptible to age-related degradation after 20+ years:

- SRAM cell leakage or latch-up: Causes intermittent data corruption, especially at elevated temperatures

- Capacitor aging on power decoupling circuits: Leads to voltage droop and read/write errors

- Oxidation of edge connectors or socket contacts: Increases impedance and causes bus timeouts

- Latch failure in address decoder logic: Results in incorrect memory mapping or bus conflicts

- Firmware-less design: No self-diagnostics; faults are only detectable via application-level checksums

Environmental stressors like thermal cycling, radiation (in nuclear settings), and vibration accelerate wear. Recommended preventive actions include:

- Periodic memory integrity testing using diagnostic software (e.g., VxWorks BSP tests)

- Cleaning and reseating the card annually

- Monitoring VME bus error counters on the system controller

- Maintaining multiple verified spares with burn-in testing

VMIC VMIVME-1128

Lifecycle Status and Migration Strategy

VMIC was acquired by GE Fanuc in 2003, and the VMIVME-1128 was discontinued shortly thereafter. The product line was eventually sunsetted under Emerson’s ownership. No official replacements exist, and even datasheets are now archived or paywalled.

Short-term mitigation:

- Source tested units from reputable defense/aerospace surplus suppliers (e.g., Rochester Electronics, if available)

- Implement application-level CRC or redundancy over shared memory

- Create a hardware emulator using FPGA-based VME cards (e.g., from MEN Mikro or EKF)

Long-term migration path:

- Replace VME chassis with modern VPX or CompactPCI Serial platforms featuring integrated DDR4 shared memory or PCIe peer-to-peer

- Virtualize legacy VME software on ruggedized x86 servers with VME-to-PCIe bridge cards (limited determinism)

- Full system rewrite using modern real-time OS (e.g., Linux PREEMPT_RT, QNX) and Ethernet-based time-triggered communication (e.g., TSN, DDS)

Given the mission-critical nature of many VMIVME-1128 deployments, organizations should conduct a formal obsolescence risk assessment and prioritize migration—especially in regulated industries where component traceability and long-term support are mandatory. Continuing to operate on untested surplus units poses unacceptable reliability and safety risks.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: