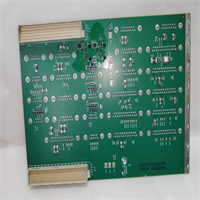

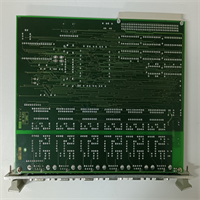

Description

Key Technical Specifications (For Spare Parts Verification)

- Model: VME-SSI

- Manufacturer: Ansaldo Automation / AVMESSI (Genoa, Italy)

- System Family: VME-based control platforms used in Ansaldo’s rail traction, hydroelectric, and industrial drives (e.g., ECOPLC, SICAM systems)

- Bus Standard: VME64 (3U or 6U form factor, typically 6U)

- Interface Type: Synchronous Serial Interface (SSI), often RS-422/485 electrical layer

- Protocol Support: Proprietary Ansaldo SSI protocol or standard SSI for absolute encoders

- I/O Channels: Typically 1–2 independent SSI channels, configurable via DIP switches or onboard jumpers

- Power Requirements: +5 VDC from VME backplane (±5% tolerance); typical current draw 1.2–2.0 A

- Physical Indicators: Status LEDs for TX/RX activity, channel fault, and board presence

- Firmware/Revision: Identified by silkscreen label (e.g., “Rev. B2”) or EPROM sticker—critical for compatibility

System Role and Downtime Impact

The VME-SSI module is typically installed in a VME chassis alongside a Motorola MVME-series CPU (e.g., MVME162 or MVME177) within Ansaldo’s legacy control cabinets. It acts as the primary link between the central processor and high-precision field devices—most commonly rotary encoders on hydro turbine shafts, traction motor position sensors in locomotives, or valve position feedback in power plant actuators. Failure of this module disrupts real-time position or speed data flow, which in many applications triggers a safety interlock or forces the system into manual mode. In critical infrastructure—such as a hydroelectric dam or mainline electric locomotive—this can result in complete operational shutdown until the module is replaced or repaired.

Reliability Analysis and Common Failure Modes

These modules were built with industrial-grade components but are now 20–30 years old. The most frequent failure mechanisms stem from aging electronics rather than design flaws. Electrolytic capacitors on the power regulation circuit often dry out, leading to voltage instability or complete power dropout. The RS-422 transceiver ICs (e.g., SN75176 or equivalent) are vulnerable to ground potential differences and lightning-induced surges, especially in outdoor or poorly grounded installations. Additionally, the VME edge connector can suffer from oxidation or mechanical wear after repeated insertions, causing intermittent bus communication errors.

A known weakness is the lack of galvanic isolation on many early versions—field-side transients can propagate directly to the VME backplane, potentially damaging the CPU or other modules. For preventive maintenance, technicians should:

- Inspect for bulging or leaking capacitors during routine cabinet checks

- Clean VME connectors with contact enhancer spray every 2–3 years

- Verify grounding integrity between field devices and control cabinet

- Monitor for intermittent encoder loss in system logs—a classic early symptom of SSI driver degradation

VME-SSI AVMESSI ANSALDO

Lifecycle Status and Migration Strategy

Ansaldo discontinued the VME-SSI module in the early 2000s as the company shifted toward modern PLC architectures (e.g., Simatic-based SICAM systems). Official support ended over a decade ago. Continuing to operate systems with this component carries significant risk: spare units are scarce, prices have risen sharply, and few engineers retain hands-on experience with VME diagnostics.

As a temporary measure, some operators maintain a “hot spare” inventory or engage specialized firms for board-level repair (capacitor replacement, IC reballing). However, the sustainable path is migration. Hitachi Energy (which absorbed Ansaldo’s automation business) does not offer a direct drop-in replacement, but industry-standard alternatives exist. A common approach is to replace the entire VME rack with a modern controller (e.g., Siemens S7-1500 or Rockwell ControlLogix) and use a protocol gateway (e.g., HMS Anybus or ProSoft MVI56-SSI) to interface existing SSI encoders. This requires re-engineering the control logic but eliminates single-point obsolescence risk and restores access to technical support, cybersecurity updates, and spare parts availability. Planning for this transition should begin immediately if the system remains mission-critical.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: