Description

Key Technical Specifications (Spare Part Verification)

- Product Model: RPS6U

- Manufacturer Part Number: 200-582-200-011

- Manufacturer: Vibro-Meter (Curtiss-Wright)

- Product Family: VM600 Monitoring System

- Input Voltage: Dual independent 90–264 V AC or 100–370 V DC (universal input)

- Output: 24 V DC, 6 A continuous per channel (dual-redundant outputs)

- Redundancy Mode: Active/standby with automatic failover

- Mounting: 3-slot width in standard VM600 19″ rack

- Operating Temperature: 0°C to +60°C

- Safety & Compliance: CE, UL 61010, IEC 61010 (as originally certified)

- Status Indication: LED indicators for input OK, output OK, redundancy active

System Role and Downtime Impact

The RPS6U is the primary power source for the Vibro-Meter VM600 rack, which is commonly deployed in power generation, oil & gas, and heavy industry for turbine, compressor, and pump monitoring. It supplies conditioned 24 V DC to all I/O, processing, and communication modules within the chassis.

Although designed with dual-input redundancy, many legacy installations operate with only one AC feed due to original design constraints or degraded infrastructure. In such cases, failure of the RPS6U results in complete loss of the VM600 rack, disabling all vibration monitoring, trip logic, and data transmission functions. This can lead to either an unmonitored machine (high risk of undetected faults) or an automatic process shutdown if the VM600 is integrated into a plant ESD system. Even in fully redundant configurations, a failed RPS6U reduces system resilience and may trigger alarms requiring immediate attention during critical operations.

Reliability Analysis and Common Failure Modes

Despite its robust industrial design, the RPS6U is susceptible to component aging after 10–15 years of service. The dominant failure mode is electrolytic capacitor degradation in the primary-side filtering and secondary-side regulation circuits. This leads to output voltage ripple, thermal shutdowns, or complete loss of regulation under load.

Other frequent issues include:

- Failure of switching transistors or flyback diodes due to thermal stress, causing intermittent output dropout

- Corrosion on terminal blocks or internal PCB traces, especially in humid or corrosive environments

- Wear-out of cooling fan bearings (in high-temperature variants), resulting in overheating and thermal throttling

A key design limitation is the lack of remote health monitoring—status must be verified visually via front-panel LEDs or inferred from system alarms. Additionally, the module does not support hot-swap in all rack configurations, complicating replacement during operation.

Recommended preventive actions:

- Measure output voltage and ripple annually using a calibrated multimeter or oscilloscope

- Inspect terminal tightness and signs of arcing at input/output connections

- Clean ventilation slots and internal dust buildup during scheduled outages

- Verify redundancy functionality by simulating input power loss (if operational procedures allow)

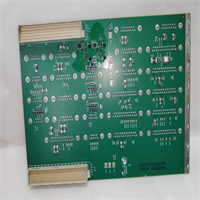

Vibro-meter VM600 RPS6U 200-582-200-011

Lifecycle Status and Migration Strategy

Vibro-Meter (now under Curtiss-Wright) has discontinued the RPS6U (200-582-200-011). No new units are manufactured, and official repair services are no longer offered. Remaining inventory is restricted to third-party vendors, often at premiums exceeding $2,000 per unit, with uncertain reliability and no OEM warranty.

Interim mitigation strategies include:

- Maintaining at least one tested spare RPS6U in climate-controlled storage

- Using external redundant DIN-rail power supplies as a temporary bypass (requires wiring modification and validation)

- Engaging specialized electronics firms for board-level refurbishment (capacitor replacement, thermal imaging inspection)

For long-term reliability, migration to the VM600 MK2 platform or integration into the Curtiss-Wright Pegasus condition monitoring ecosystem is recommended. These newer systems feature:

- Modular, hot-swappable power supplies with digital health reporting

- Native Ethernet, Modbus TCP, and OPC UA connectivity

- Enhanced cybersecurity and remote diagnostics

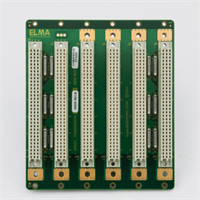

Migration typically involves replacing the entire rack backplane and I/O modules but preserves field sensor wiring through terminal block adapters. Planning this transition during major overhauls minimizes downtime and aligns asset health monitoring with current industry standards.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: