Description

Technical Specifications (Spare Parts Verification)

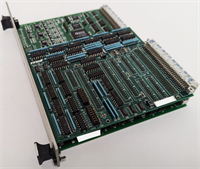

- Product Model: IOC4T (200-560-000-018 and 200-560-101-015)

- Manufacturer: Vibro-meter (Baker Hughes)

- System Family: VM600 Machinery Protection System

- Mounting: 3U height, occupies one slot in standard VM600 chassis (e.g., CHS6U)

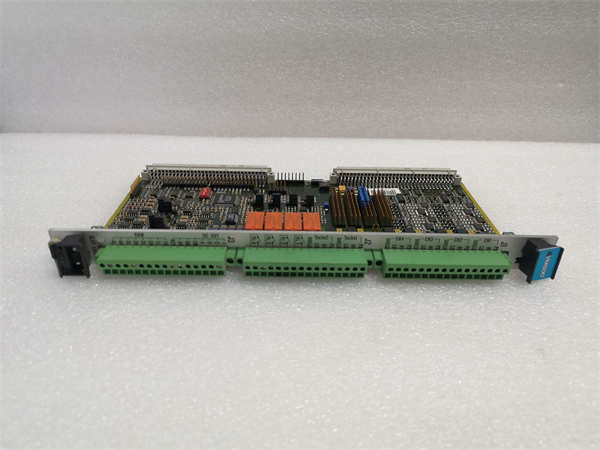

- Communication Interfaces:

- 1 × 10/100 Mbps Ethernet (RJ45) for VM600 Manager or OPC server

- 1 × RS-485 (Modbus RTU) for DCS integration

- Optional fiber optic port (depending on suffix)

- I/O Capabilities:

- 4 × Form C relay outputs (rated 2 A @ 30 V DC) for alarm/trip

- 4 × analog outputs (0–20 mA or 4–20 mA, configurable)

- Power Source: +24 V DC from VM600 backplane

- Configuration: Via VM600 Manager software (Windows-based, legacy versions required)

- Indicators: Status, Ethernet activity, fault LEDs on front panel

- Firmware Dependency: Must match CPU60 and other modules in the rack

System Role and Downtime Impact

The IOC4T module resides in the main electronics rack of a VM600 system, typically installed adjacent to the CPU60 processor and vibration input cards. It acts as the sole bridge between the protection logic and the plant-wide control infrastructure. All alarm notifications, trip commands, and live vibration data pass through this module to the DCS, HMI, or historian.

If the IOC4T fails, the VM600 system becomes operationally blind to operators—even if internal monitoring continues. Critical events like high vibration or bearing temperature will not trigger DCS alarms or initiate automatic shutdown sequences. In regulated industries (e.g., oil & gas, power), this constitutes a violation of API 670 and may force derating or manual supervision of the machine. Recovery requires not only hardware replacement but also re-loading the correct configuration file, which is often lost in older installations.

Reliability Analysis and Common Failure Modes

Despite industrial-grade construction, the IOC4T is vulnerable to several age-related failure mechanisms:

Common failure modes include Ethernet PHY chip degradation due to thermal cycling, resulting in intermittent network drops or complete link loss. Relay contact welding can occur after repeated trip events, causing false “stuck” states. The analog output drivers are sensitive to ground loops, leading to signal drift or saturation. Additionally, EEPROM corruption during unclean power cycles may erase IP settings or Modbus mapping.

A key design limitation is the lack of redundant communication paths: the IOC4T is a single point of failure for all external data exchange. Furthermore, its reliance on legacy Windows-based configuration tools complicates recovery if original project files are unavailable.

Preventive maintenance recommendations:

- Verify network connectivity and Modbus polling response monthly

- Perform relay contact resistance tests during outages

- Archive IOC4T configuration files (.v6c) in a version-controlled repository

- Maintain a powered spare unit with identical firmware and settings

- Inspect for signs of overheating near the Ethernet magnetics

Vibro-meter 200-560-000-018 200-560-101-015 VM600 IOC4T

Lifecycle Status and Migration Strategy

Baker Hughes no longer produces or officially supports the IOC4T. While limited refurbished units may be available through authorized service centers, there is no assurance of long-term supply or technical assistance.

Short-term risk mitigation includes:

- Implementing external protocol converters to monitor IOC4T health via heartbeat signals

- Stocking at least one pre-configured spare with verified operation

- Isolating the VM600 network segment to reduce cyber exposure (as the module lacks modern security features)

For sustainable operation, Baker Hughes recommends migrating the entire VM600 system to the Bently Nevada System 1 platform. The IOC4T has no direct replacement within the VM600 family, though some sites have used third-party gateways (e.g., HMS Anybus) to extract Modbus data—but this adds complexity and does not restore full protective functionality.

A full migration path involves:

- Replacing the VM600 rack with a System 1 Data Manager and 3500/XP I/O

- Reusing existing proximity probes and cabling where possible

- Revalidating all alarm and trip setpoints per API 670 5th Edition

- Integrating with modern asset performance management (APM) platforms via OPC UA or MQTT

Given the safety and compliance implications, facilities relying on IOC4T modules should initiate a formal obsolescence management plan immediately.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: