Description

Technical Specifications (For Spare Parts Verification)

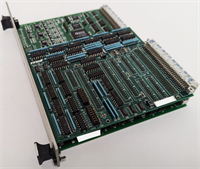

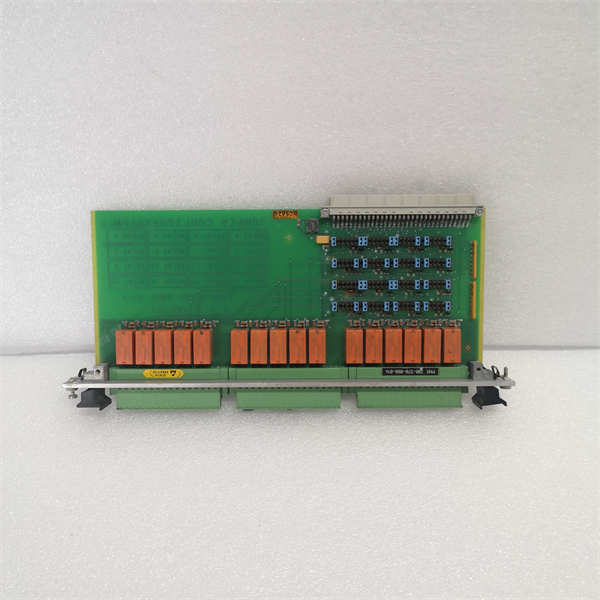

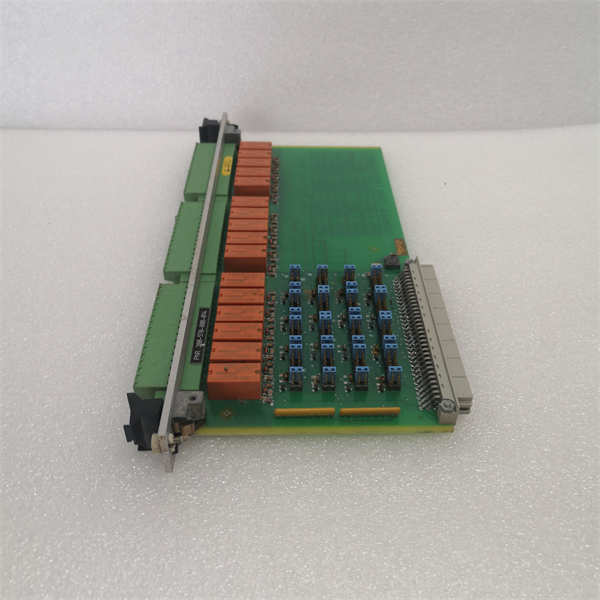

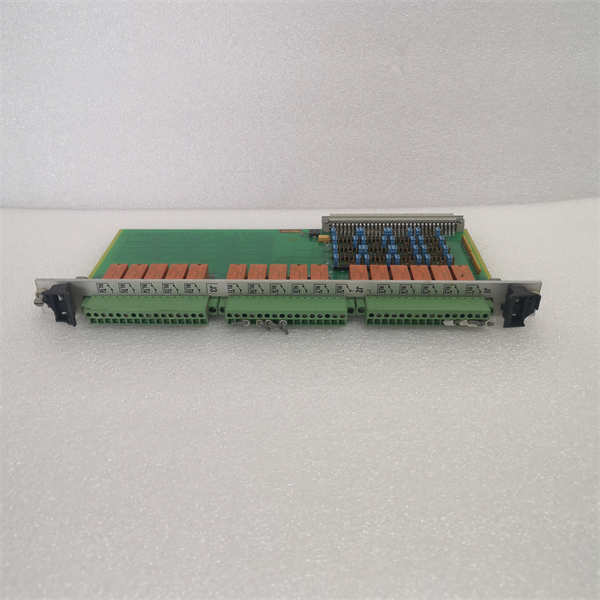

- Product Model: 200-570-000-014 / 200-570-101-013

- Manufacturer: Vibro-Meter (Meggitt / Spectris)

- System Compatibility: VM600 Machinery Protection System

- Module Type:

- 200-570-000-014: 4-channel dynamic signal input (for accelerometers or proximity probes)

- 200-570-101-013: 8-channel electromechanical relay output (alarm/trip)

- Input Range (000-014): ±10 VDC, configurable filtering and integration

- Relay Rating (101-013): 250 VAC / 30 VDC, 2 A resistive

- Backplane Interface: Proprietary VM600 Eurocard bus (3U format)

- Diagnostic Features: Front-panel LEDs for channel OK, alarm, and module status

- Power Supply: +5 VDC and ±15 VDC via backplane

- Mounting: Plug-in to standard VM600 chassis (e.g., 200-900-xxx series)

- Certification: CE, CSA, suitable for SIL-rated applications when used in full VM600 safety loop

System Role and Downtime Impact

These modules are integral to the VM600 system installed on critical rotating machinery—such as steam turbines in power stations or centrifugal compressors in LNG plants. The 200-570-000-014 conditions raw vibration signals from sensors and feeds them to the central processing unit, while the 200-570-101-013 provides fail-safe relay contacts that trigger emergency shutdowns when vibration thresholds are exceeded. If either module fails, the protection system may lose visibility into machine health or be unable to initiate a trip. In worst-case scenarios, this could lead to catastrophic mechanical failure, secondary damage, and extended plant outages lasting weeks, with repair costs running into millions of dollars.

Reliability Analysis and Common Failure Modes

Many VM600 systems have operated reliably for 20+ years due to robust industrial design. However, aging introduces predictable vulnerabilities. The most common failure modes include:

- Electrolytic capacitor degradation in the analog front-end of the 200-570-000-014, causing signal drift or noise

- Relay contact welding or coil burnout in the 200-570-101-013 due to repeated switching or inductive kickback

- Corrosion on edge connectors from humidity or chemical exposure, leading to intermittent backplane communication

- Firmware corruption in associated CPU modules (e.g., 200-910-xxx), rendering I/O modules non-functional even if hardware is intact

A key design limitation is the lack of hot-swap capability and dependency on obsolete calibration tools (e.g., VM600 Configurator on Windows XP). Additionally, the analog circuitry is sensitive to ground loops and EMI in modern high-voltage environments.

Recommended preventive actions:

- Perform annual functional tests using calibrated signal injectors

- Inspect relay contacts for pitting or sticking during outages

- Verify signal integrity with oscilloscope measurements at module inputs

- Maintain at least one matched spare pair (input + output) with verified calibration certificate

Vibro-meter 200-570-000-014 200-570-101-013 VM600

Lifecycle Status and Migration Strategy

Spectris has discontinued the VM600 platform and offers no new modules, repairs, or software support. Continued operation carries significant risk: unavailability of calibrated spares, inability to validate system performance, and non-compliance with modern functional safety standards (e.g., IEC 61511).

As a temporary measure, some service providers offer board-level repair and recalibration—but traceability to original OEM specifications cannot be guaranteed.

The official migration path is to upgrade to the VM800 platform, which provides:

- Full backward compatibility with existing proximity probes and cabling (via adapter terminals)

- Enhanced diagnostics, cybersecurity features, and OPC UA connectivity

- Compliance with IEC 61508 SIL 2/3 and API 670 5th Edition

Migration requires:

- Replacement of all VM600 chassis, power supplies, and I/O modules

- Reconfiguration of alarm logic in the new VM800 Workbench software

- Recertification of the entire protection loop, including sensor verification

Facilities should prioritize migration during next major turnaround to eliminate obsolescence risk and ensure long-term compliance with safety and insurance requirements.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: