Description

Technical Specifications (For Spare Parts Verification)

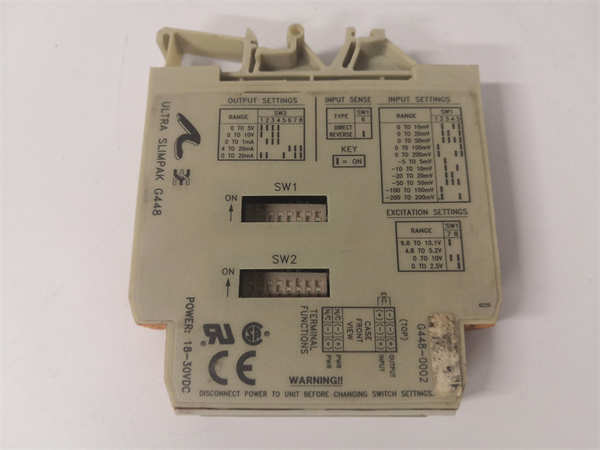

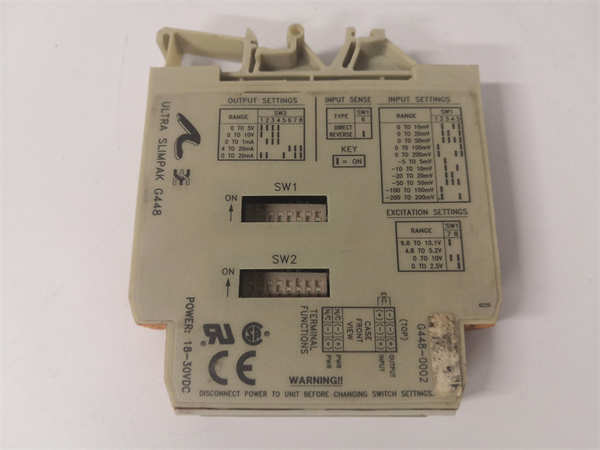

- Product Model: G448-0002

- Manufacturer: ULTRA / Eaton (SlimPak product line)

- System Family: ULTRA SlimPak Series 400/500 PLC platform

- Input Type: Sinking (NPN-compatible), 24 VDC nominal

- Number of Channels: 16 isolated inputs

- Input Voltage Range: 15–30 VDC

- Input Current: ~3.5 mA per channel at 24 VDC

- Isolation: Optical isolation between field and backplane

- Mounting: Snap-in base for SlimPak I/O chassis (e.g., G400/G500 racks)

- Connector: Screw-terminal or removable terminal block (depends on base unit)

- Status Indication: Per-channel LED (green)

ULTRA SLIMPAKG448-0002

System Role and Downtime Impact

The G448-0002 serves as a core digital input module in ULTRA SlimPak-based control systems, commonly deployed in packaging, material handling, and small-scale process machinery from the 1990s to early 2000s. It interfaces directly with proximity sensors, limit switches, and safety interlocks, converting real-world discrete signals into logic states for the CPU. If this module fails—due to channel burnout, communication loss, or power surge—the affected inputs become unresponsive, leading to incomplete machine cycles, safety lockouts, or full system halt. In many installations, it is not redundant, meaning a single point of failure can stop an entire production cell.

Reliability Analysis and Common Failure Modes

Despite its age, many G448-0002 modules remain operational due to robust industrial design and low-complexity circuitry. However, decades of service expose inherent vulnerabilities. The most common failure mode is input channel degradation caused by repeated exposure to inductive kickback from unshielded sensors or lack of flyback diodes, which damages the internal optocouplers over time. A secondary issue is terminal corrosion or cold solder joints, especially in humid or washdown environments, leading to intermittent signals.

The module’s primary design weakness is its lack of surge suppression on individual channels—it relies entirely on external protection. Additionally, while it does not use battery-backed memory (as it is an I/O card), it depends on stable backplane power; voltage sags or noise on the +5 V rail can cause communication timeouts with the CPU.

For preventive maintenance, technicians should:

- Inspect terminal blocks for oxidation or loose wires during scheduled outages

- Verify input signal integrity using a multimeter under load (not just open-circuit voltage)

- Ensure all field devices include proper snubber circuits or diodes to suppress transients

- Keep spare units in climate-controlled storage to avoid capacitor aging or PCB delamination

ULTRA SLIMPAKG448-0002

Lifecycle Status and Migration Strategy

The ULTRA SlimPak platform, including the G448-0002, was officially discontinued in the mid-2000s following Eaton’s consolidation of automation product lines. No factory support, firmware updates, or new units are available. Continued use carries significant risk: spare parts are scarce, counterfeit units occasionally appear on gray markets, and repair expertise is increasingly rare.

As a temporary measure, facilities can source tested surplus units from specialized industrial brokers or consider board-level repair if only one or two channels fail. However, long-term reliance on such solutions is unsustainable.

The recommended migration path is a full upgrade to a modern micro-PLC platform. Eaton no longer supports SlimPak, but industry-standard alternatives include:

- Allen-Bradley Micro850 with 1769-IA16 digital input modules

- Siemens SIMATIC S7-1200 with SM1221 DI 16x24VDC

- AutomationDirect DirectLOGIC DL205 with D2-16ND3

Migration requires re-engineering the I/O wiring, updating ladder logic, and revalidating safety functions—but eliminates obsolescence risk and often improves diagnostics, connectivity, and maintainability. For critical legacy lines where immediate replacement is impractical, implementing a “hot spare” strategy with a verified backup module is advised.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: