Description

Key Technical Specifications (for Spare Verification)

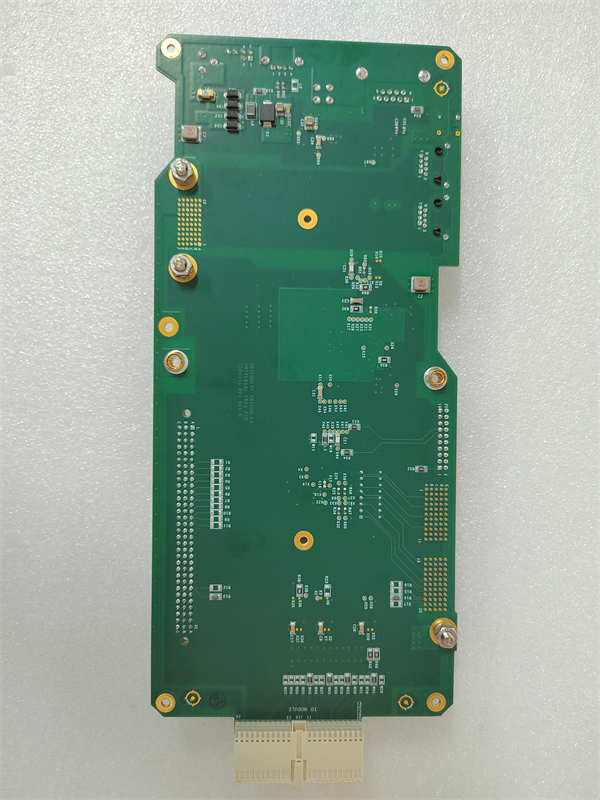

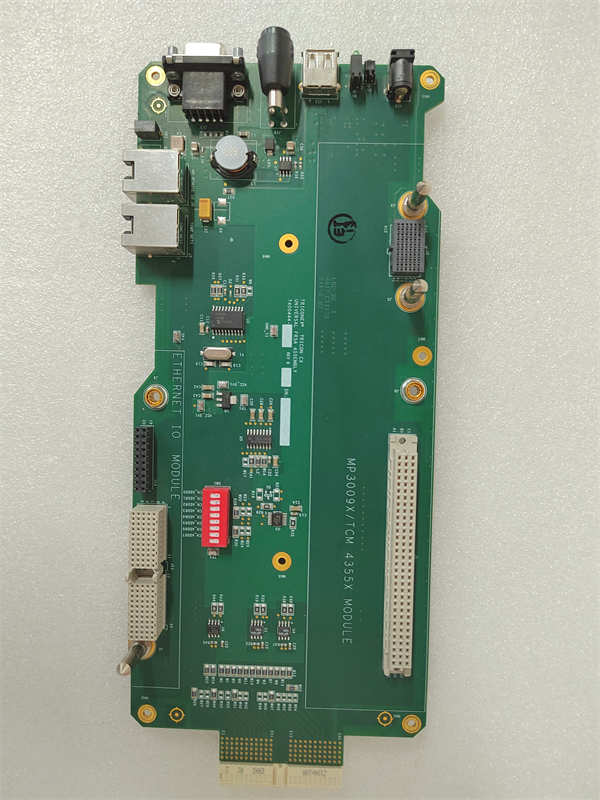

- Product Model: MP3009X and TCM 4355X

- Manufacturer: Triconex (Schneider Electric)

- System Family: Tricon v9 / Tricon Classic (pre-eVolution platform)

- MP3009X Function: Main processor module with TMR architecture (three independent CPUs with voting)

- TCM 4355X Function: Tricon Chassis Module – manages I/O communication, power monitoring, and module synchronization

- Installation Slot: MP3009X occupies slots 1–3; TCM 4355X is a fixed component of the 4355-series chassis

- Communication: Proprietary high-speed parallel bus to I/O modules (e.g., 3503E, 3664E)

- Power Requirements: +5 V, ±12 V, +24 V from redundant power supplies (e.g., 8311A)

- Diagnostic Indicators: Multiple LEDs per module for ACTIVE, PASS, FAULT, and MAINT states

- Firmware Dependency: Requires matching firmware across all three MP3009X units in a chassis

System Role and Downtime Impact

The MP3009X and TCM 4355X are foundational components of the Tricon v9 safety system. The MP3009X executes all safety-critical logic in a triple-redundant configuration, while the TCM 4355X ensures synchronized communication between processors and I/O modules. These modules are typically deployed in emergency shutdown (ESD), fire & gas (F&G), and burner management systems (BMS) in oil & gas, chemical, and power generation facilities. A failure in either component—especially the TCM 4355X, which has no hot-swap capability—will cause the entire Tricon chassis to enter a safe state, triggering a full plant or unit shutdown. Given their role in SIL 3 applications, unplanned downtime carries not only production loss but also regulatory and safety compliance risks.

Reliability Analysis and Common Failure Modes

These modules have demonstrated long service life due to robust industrial design, but age-related degradation is now prevalent. The MP3009X commonly fails due to electrolytic capacitor aging on the internal DC-DC converter boards, leading to voltage instability and spontaneous reboots. The TCM 4355X is susceptible to backplane connector corrosion and solder joint fatigue from thermal cycling, which can disrupt the critical timing signals between processors. Both modules rely on lithium battery-backed SRAM for program retention; battery depletion (typically after 8–12 years) can result in logic loss during power interruptions. As a maintenance best practice, operators should:

- Monitor chassis diagnostic logs for “Module Re-sync” or “Voltage Warning” events

- Perform annual infrared thermography on the chassis to detect abnormal heating

- Replace backup batteries proactively if runtime exceeds 7 years

- Clean chassis ventilation filters quarterly to prevent overheating

MP3009X TCM 4355X TRICONEX

Lifecycle Status and Migration Strategy

Both MP3009X and TCM 4355X have been officially declared obsolete by Schneider Electric, with no new units available from the manufacturer. Continued operation carries high risk: verified spares are scarce, counterfeit parts are increasingly common, and technical support is limited to third-party specialists. In the short term, facilities may mitigate risk by sourcing tested, tagged spares from certified vendors and implementing rigorous preventive maintenance. However, the only sustainable path is migration. Schneider Electric’s recommended upgrade path is to the Triconex eVolution platform (e.g., TCM 4451 chassis with MP4000 processors). This migration requires:

- Full re-compilation of safety logic in Triconex Enhanced Development Environment (EDE)

- Replacement of all I/O modules with eVolution-compatible equivalents

- Potential re-engineering of field wiring due to terminal block differences

While capital-intensive, this transition restores access to factory support, cybersecurity updates, and modern diagnostics—critical for maintaining functional safety compliance under IEC 61511.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: