Description

Key Technical Specifications (For Spare Parts Verification)

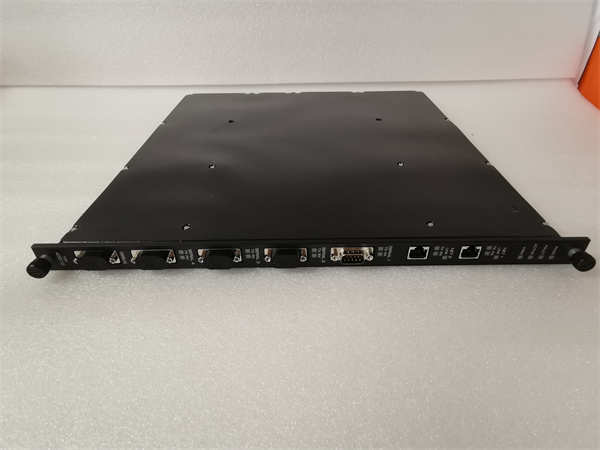

- Product Model: 4351B

- Manufacturer: Triconex (Schneider Electric)

- System Platform: Tricon v10 and earlier TMR safety controllers

- Module Type: Analog Input (AI), 16 channels

- Input Signal: 4–20 mA (sinking), compatible with HART-enabled transmitters

- Input Impedance: 250 ohms per channel

- Resolution: 16-bit A/D conversion

- Accuracy: ±0.05% of full scale at 25°C

- Diagnostic Coverage: Channel-level open-circuit detection, overrange/underrange monitoring, and TMR voting mismatch alerts

- Power: Supplied via Tricon chassis backplane (redundant +5 V and ±12 V rails)

- Physical Form: Full-height I/O module, occupies one dedicated slot in Tricon chassis

- Firmware Dependency: Requires Tricon MP3008/MP3009 main processors with compatible firmware (typically pre-v11.x)

System Role and Downtime Impact

The 4351B is a foundational input interface in Tricon-based Safety Instrumented Systems (SIS), widely deployed in refineries, petrochemical facilities, and offshore platforms. It digitizes analog process variables from critical field instruments—such as reactor pressure, vessel level, or turbine exhaust temperature—and delivers voted data to the triple-redundant main processors for safety logic evaluation. Because it operates within a TMR architecture, single-channel failures are typically masked, but complete module failure or undetected drift can lead to either a dangerous failure (failure to detect hazardous conditions) or a spurious trip.

In continuous-process operations, an unplanned shutdown triggered by faulty input data can result in significant financial loss and safety exposure during restart. Conversely, latent degradation in signal accuracy may compromise compliance with IEC 61511 functional safety requirements. Since the 4351B cannot be hot-swapped in legacy Tricon systems, replacement generally requires a planned process interruption—making proactive spares management essential.

Reliability Analysis and Common Failure Modes

Despite its fault-tolerant design, the 4351B is vulnerable to long-term electronic wear. The most common failure mechanisms include:

- Degradation of precision resistors and operational amplifiers in the input conditioning circuitry, causing gain/offset drift that affects measurement accuracy.

- Failure of isolation barriers due to voltage transients or ground loops, leading to communication faults or channel dropouts.

- Corrosion on terminal blocks or backplane connectors in high-humidity or corrosive environments, increasing contact resistance and signal noise.

A notable limitation of early revisions is the absence of comprehensive self-diagnostics for subtle analog drift—meaning small deviations may not trigger alarms until they exceed safety thresholds. Additionally, the module’s reliance on aging surface-mount components (no longer available from original suppliers) complicates board-level repair.

Recommended maintenance practices include: performing periodic loop calibration using certified mA simulators, verifying HART communication integrity, inspecting terminal torque and shielding continuity, and monitoring module status via Triconex Enhanced Diagnostic Monitor (EDM). Any unit exhibiting intermittent channel faults or unexplained diagnostic warnings should be removed from service.

Triconex 4351B

Lifecycle Status and Migration Strategy

Schneider Electric has formally discontinued the 4351B as part of the Tricon v10 platform end-of-life plan. No new units are available, and factory repair services are no longer offered. Continuing to operate with this obsolete module introduces escalating risks: diminishing supply of functionally tested spares, inability to validate performance against original specifications, and potential audit findings during functional safety assessments.

As an interim measure, facilities should secure at least one fully tested spare and consider third-party refurbishment that includes component rework, recalibration, and full TMR functional validation. For long-term sustainability, Schneider recommends migrating to the Triconex Trident platform, which features the 4751E analog input module—a successor offering enhanced diagnostics, native HART multiplexing, and integration with modern engineering tools like Triconex Workbench.

Migration to Trident requires re-engineering the safety application and revalidating the entire SIS to SIL requirements, but preserves field wiring through adapter solutions. Until migration is feasible, rigorous testing, calibration, and spares verification remain critical to maintaining safety integrity and operational continuity.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: