Description

Technical Specifications (For Spare Parts Verification)

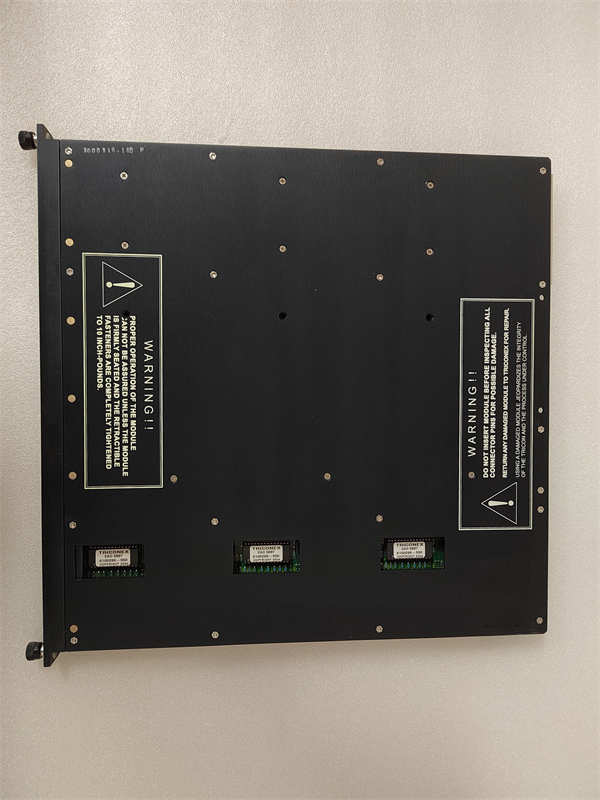

- Product Model: 3805E

- Manufacturer: Triconex (Schneider Electric)

- System Platform: Tricon v9 / v10 Triple Modular Redundant (TMR) Safety System

- Module Type: Main Processor (MP) – one of three identical modules operating in 2oo3 voting architecture

- Processing Architecture: Proprietary TMR microprocessor with hardware-level synchronization

- Memory: Onboard application memory (non-volatile); retains program without battery backup

- Backplane Interface: Connects via Tricon chassis backplane to I/O modules and power supplies

- Diagnostic Capabilities: Continuous self-test, fault logging, and status reporting to TriStation 1131

- Redundancy: Operates in triplicated set; system tolerates single or dual module failure

- Operating Temperature: 0°C to 60°C

- Certification: Compliant with IEC 61508 SIL 3, ISA S84.01, and other functional safety standards

System Role and Downtime Impact

The 3805E is the computational heart of legacy Tricon v9/v10 safety systems, widely deployed in oil & gas, refining, petrochemical, and power generation facilities for critical applications such as emergency shutdown (ESD), burner management (BMS), and high-integrity pressure protection (HIPPS). It executes the safety application logic developed in TriStation 1131 and continuously cross-checks results with its two redundant peers. If one 3805E fails, the system continues in “degraded” mode; however, if a second fails before replacement, the entire Tricon chassis may go into a safe state—initiating a full process shutdown. Given its role in life-safety and environmental protection systems, unavailability of a verified spare can delay restarts for days or weeks, with significant financial and regulatory consequences.

Reliability Analysis and Common Failure Modes

The 3805E benefits from Triconex’s robust TMR design but is not immune to aging effects. The most common failure mode is memory corruption or firmware instability, often triggered by voltage sags on the 24 VDC power rails or cumulative radiation-induced bit flips in long-running systems. A secondary issue is backplane connector fatigue, where repeated thermal cycling causes intermittent contact, leading to “module mismatch” or “sync loss” faults. Although the module contains no batteries or moving parts, contamination from airborne sulfur or dust in non-climate-controlled shelters can corrode internal traces over decades of service. For preventive maintenance, technicians should: (1) monitor power supply health and ripple on the Tricon chassis, (2) perform annual diagnostics via TriStation 1131 to verify module synchronization and fault logs, (3) inspect and clean backplane fingers during routine outages, and (4) store spares in static-shielded containers with humidity control.

TRICONEX 3805E

Lifecycle Status and Migration Strategy

Schneider Electric has formally discontinued the 3805E and migrated support to the Tricon v11 platform (e.g., 3815E processor) and the newer Triconex CX series. No new 3805E modules are manufactured, and official repair services are no longer available. Continued operation carries risks of irreversible failure, lack of engineering support, and incompatibility with modern cybersecurity requirements. As a short-term measure, facilities can acquire tested units from certified surplus vendors—but must validate full TMR synchronization and application integrity after installation. The strategic migration path is to upgrade to Tricon v11, which offers backward compatibility with existing I/O modules and allows reuse of much of the safety logic (with recompilation in updated TriStation). This requires chassis replacement, updated engineering licenses, and requalification per IEC 61511—but preserves the proven TMR architecture while extending system life by 15+ years. For organizations unable to fund a full upgrade, maintaining a minimum of two fully tested 3805E spares per critical system remains a prudent risk-mitigation practice.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: