Description

Key Technical Specifications (For Spare Parts Verification)

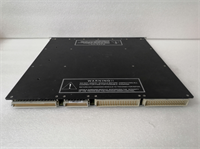

- Product Model: 3625A

- Manufacturer: Triconex (Schneider Electric)

- System Family: Tricon v9/v10/v11 Triple Modular Redundant (TMR) Process Safety System

- Output Channels: 2 independent channels, each triplicated in hardware (TMR architecture)

- Output Signal Type: 4–20 mA or 0–20 mA (software-configurable), sink/source capable

- Load Drive Capability: Up to 750 Ω at 24 VDC

- Update Rate: 50 ms nominal (synchronized with main processor scan)

- Diagnostics: Continuous channel-level diagnostics including open-circuit, short-circuit, and out-of-range detection

- Communication: Interfaces with Main Processor (MP) via Tricon backplane; status reported via TriStation 1131

- Mounting: Occupies one I/O slot in standard Tricon chassis (e.g., 8310/8311)

- Certification: Designed for use in SIL 3 applications per IEC 61508; certified by TÜV, FM, CSA for safety-critical service

System Role and Downtime Impact

The 3625A serves as the final actuation interface in Tricon-based Safety Instrumented Systems (SIS), commonly deployed in oil & gas, chemical, and power generation facilities. It converts voted digital commands from the three redundant Main Processors into a fail-safe analog signal that drives control valves, dampers, or speed controllers. Because it operates within a TMR architecture, a single channel fault does not cause system failure—but a complete module failure (e.g., power supply collapse or backplane communication loss) results in both outputs going to a predefined safe state (typically 0 mA or last good value hold, depending on configuration). In critical applications such as emergency depressurization or turbine overspeed protection, this may initiate a full plant shutdown. Given its role in safety loops, unplanned failure of the 3625A carries both operational and regulatory consequences.

Reliability Analysis and Common Failure Modes

Despite the inherent fault tolerance of the Tricon platform, the 3625A is subject to several age-related and environmental failure mechanisms:

- Output driver degradation: Power transistors or current-regulation ICs degrade over time under continuous load, leading to output drift or inability to drive high-impedance loads.

- Backplane connector fatigue: Repeated thermal cycling causes micro-cracks in solder joints or socket wear, resulting in intermittent communication with the Main Processors.

- Capacitor aging: Electrolytic capacitors in the local DC-DC converter dry out, causing voltage ripple that triggers internal diagnostics or resets.

- Configuration corruption: While rare, EEPROM errors can alter output scaling or fail-safe behavior if exposed to strong EMI or radiation (e.g., near NDT equipment).

Recommended preventive actions:

- Perform annual loop calibration using a precision mA source/sink to verify linearity and response

- Inspect module seating and backplane contacts during routine maintenance outages

- Monitor diagnostic logs in TriStation for “Channel Fault” or “Module Health” warnings

- Maintain at least one fully tested spare per critical SIF, stored in ESD-safe, climate-controlled conditions

Triconex 3625A

Lifecycle Status and Migration Strategy

Schneider Electric has formally discontinued the 3625A as part of the broader phase-out of legacy Tricon v9/v10 hardware. While the Tricon platform remains supported through v11 and Triconex eXpress, new production of the 3625A ceased years ago. OEM repair services are limited, and counterfeit or untested units have appeared in secondary markets.

For facilities unable to execute a full safety system upgrade immediately, recommended interim measures include:

- Procuring spares only from suppliers providing full functional test reports under TMR simulation

- Implementing periodic hot-swap testing (where system design permits) to validate failover behavior

- Archiving original configuration files (.PRJ) and firmware versions for rapid recovery

The official migration path is to transition to the Triconex eXpress platform or Tricon v11 with modern I/O modules such as the 3725 (analog output successor). These newer modules offer enhanced diagnostics, higher density, and improved cybersecurity features while maintaining TMR integrity. However, migration requires re-engineering of I/O wiring (due to different terminal block layouts), re-validation of all SIFs, and potential updates to application logic. A risk-based assessment—considering SIL requirements, regulatory deadlines, and asset lifecycle—should determine the optimal timing for this transition.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: