Description

Technical Specifications (For Spare Verification)

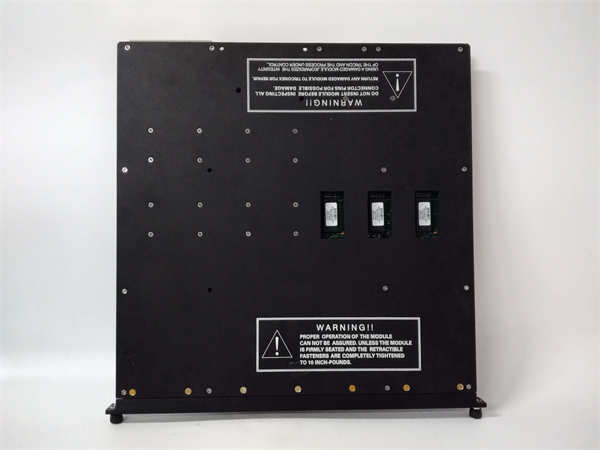

- Product Model: 3604E

- Manufacturer: Triconex

- System Compatibility: Triconex Tricon (v9 and earlier) safety controllers

- Output Type: Electromechanical relays (form C contacts)

- Number of Outputs: 8 independent TMR logical outputs (each driven by three physical relays in voted configuration)

- Contact Rating: 2 A @ 30 VDC / 250 VAC resistive load

- Coil Voltage: Powered from internal system supply (no external coil power required)

- Isolation: >1500 VAC between field and logic circuits

- Diagnostics: Built-in contact monitoring, coil health check, and mismatch detection reported to main processor

- Form Factor: Standard Tricon I/O module (fits 4-slot or 8-slot chassis)

- Certifications: IEC 61508 SIL 3, API 670 compliant

-

Triconex 3604E

System Role and Downtime Impact

The 3604E provides direct, fail-safe actuation capability in Triconex-based Emergency Shutdown (ESD), Fire & Gas (F&G), and turbine protection systems. Unlike solid-state output modules, it uses physical relay contacts to switch field circuits—making it suitable for applications requiring galvanic isolation, high inrush tolerance, or compatibility with legacy 120/240 VAC solenoids. Each logical output is implemented via three relays under TMR voting; only if two or more agree is the field device energized. This architecture ensures high fault tolerance. However, if relay contacts weld, erode, or develop high resistance due to arcing, the module may fail to de-energize a valve during a trip event—a dangerous undetected failure. A complete module fault typically forces the associated SIF into bypass, which may violate regulatory requirements under IEC 61511 and require immediate operational restrictions. Replacement demands physical swap, loop functional testing, and revalidation of the entire safety function.

Reliability Analysis and Common Failure Modes

Despite its robust TMR design, the 3604E is inherently vulnerable due to its electromechanical nature:

- Contact erosion and welding: Repeated switching of inductive loads (e.g., solenoids) causes arcing, leading to pitting, increased contact resistance, or permanent welding—especially if snubber circuits are absent in the field wiring.

- Coil degradation: Relay coils can fail open due to thermal stress or insulation breakdown after years of continuous operation.

- Mechanical fatigue: Spring mechanisms weaken over time, reducing contact force and increasing bounce duration, which accelerates wear.

- Terminal corrosion: In humid or corrosive environments, oxidation at screw terminals increases resistance, causing voltage drop and potential failure to activate low-power devices.

A key limitation is that while the module performs self-tests (e.g., coil continuity, contact position feedback), it cannot detect partial contact degradation unless it causes a voting mismatch.

Recommended preventive actions include:

- Performing annual functional tests by commanding each output and verifying field device response.

- Inspecting relay status LEDs and diagnostic tags for “contact mismatch” or “coil fault” indications.

- Ensuring proper surge suppression on inductive field devices to minimize contact arcing.

- Storing spares in dry, vibration-free, ESD-safe conditions to preserve mechanical integrity.

-

Triconex 3604E

Lifecycle Status and Migration Strategy

Schneider Electric has formally discontinued the 3604E as part of the end-of-life roadmap for legacy Tricon (v9) systems. No new units are available through authorized channels. Remaining inventory consists of used modules with unknown switching cycles and contact condition—posing significant reliability risks. Continued use exposes facilities to potential failure in critical shutdown sequences and challenges in meeting audit requirements under functional safety standards.

Short-term mitigation strategies include:

- Securing at least two fully tested and verified spares per critical SIF loop.

- Engaging only vendors certified under Schneider’s Authorized Repair Program for relay replacement and recalibration.

- Implementing enhanced diagnostics via Triconex Enhanced Diagnostic Monitor (EDM) to track output health trends.

For long-term sustainability, migration to the Triconex v11 platform is strongly advised. Modern alternatives such as the T8651/T8661 solid-state digital output modules offer:

- Longer service life (no moving parts)

- Faster diagnostics and LED indication per channel

- Integrated cybersecurity features (IEC 62443 compliant)

- Continued manufacturer support and spare availability

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: