Description

Key Technical Specifications (For Spare Parts Verification)

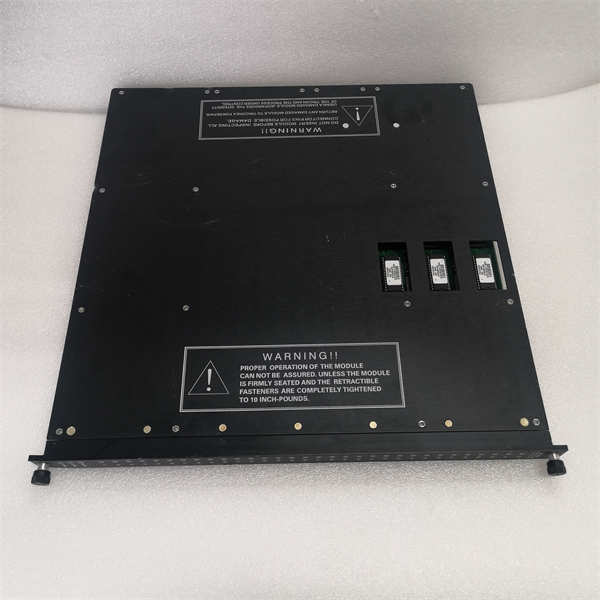

- Product Model: 3503E

- Manufacturer: Triconex / Schneider Electric

- System Family: Tricon v10 (Legacy TMR Platform)

- Module Type: Main Processor (MP)

- Redundancy Architecture: Triple-Modular Redundant (TMR) with voting

- Memory: Onboard application memory (non-volatile, battery-backed SRAM)

- Communication: Proprietary Tricon backplane bus; supports Modbus RTU via optional communication modules

- Diagnostic Coverage: Built-in self-test (BIT) on power-up and continuous runtime diagnostics

- Mounting: Slot 0 in Tricon main chassis (must be installed in all three main processor slots for full TMR operation)

- Firmware Dependency: Requires matching firmware version across all three MP modules in a chassis

System Role and Downtime Impact

The Triconex 3503E is the primary processing module in legacy Tricon v10 safety systems. It executes the safety application logic in a fault-tolerant TMR configuration, where three identical processors run in parallel and vote on outputs. This module resides in slot 0 of the main chassis and is replicated in slots 1 and 2. If one 3503E fails, the system continues to operate in a degraded 2oo3 mode. However, if a second module fails before replacement, the entire Tricon system will trip, causing an immediate and uncontrolled shutdown of the protected process—such as an emergency depressurization in oil & gas or a reactor SCRAM in chemical plants. Given its role as the brain of the safety system, its failure directly compromises functional safety integrity.

Reliability Analysis and Common Failure Modes

Although designed for high reliability, the 3503E is susceptible to age-related degradation due to its vintage electronics architecture. The most common failure modes include:

- Battery-backed SRAM corruption: The onboard memory relies on a lithium coin cell (typically CR2032 or similar) to retain the application program during power loss. After 10–15 years, battery depletion can lead to program loss, triggering a “Major Fault” and system trip upon restart.

- Electrolytic capacitor aging: Power regulation circuits on the board use aluminum electrolytic capacitors that dry out over time, leading to voltage instability, intermittent resets, or complete power-on failure.

- Connector and edge-finger corrosion: Repeated thermal cycling and exposure to industrial atmospheres can cause oxidation on the gold-plated edge connectors, resulting in intermittent communication with the backplane.

Key design vulnerabilities include dependence on non-replaceable onboard batteries (in early revisions) and lack of modern surge protection on the backplane interface. As a maintenance best practice, operators should:

- Monitor battery voltage annually via diagnostic software (if accessible)

- Perform visual inspection of the module for bulging capacitors or discoloration

- Clean edge connectors with contact enhancer during routine outages

- Maintain at least one tested spare per system, stored in climate-controlled conditions

TRICONEX 3503E

Lifecycle Status and Migration Strategy

The Triconex 3503E has been officially declared obsolete by Schneider Electric, with no new production since the mid-2010s. Continued use carries significant operational risk: spare parts are only available through third-party brokers, authenticity cannot always be guaranteed, and technical support from the OEM is limited to existing service contracts. In the event of a multi-module failure, recovery may be impossible without compatible spares.

As a temporary mitigation, facilities can:

- Source and functionally test additional 3503E units from certified surplus suppliers

- Engage specialized firms for board-level repair (e.g., capacitor rework, battery socket retrofit)

- Implement enhanced monitoring to detect early signs of module degradation

For long-term sustainability, Schneider Electric recommends migrating to the Triconex Trident platform (e.g., model MP3203) or the newer Tricon CX series. This migration typically requires:

- Re-engineering of the safety application in the new Triconex Enhanced Environment (TEE) software

- Replacement of the entire chassis, power supplies, and I/O modules

- Factory acceptance testing (FAT) and site integration validation

While migration is capital-intensive, it restores access to warranty, cybersecurity updates, and modern diagnostics—critical for maintaining compliance with IEC 61511 in regulated industries. A phased approach, starting with non-critical trains, is often used to manage cost and risk.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: