Description

Technical Specifications (For Spare Parts Verification)

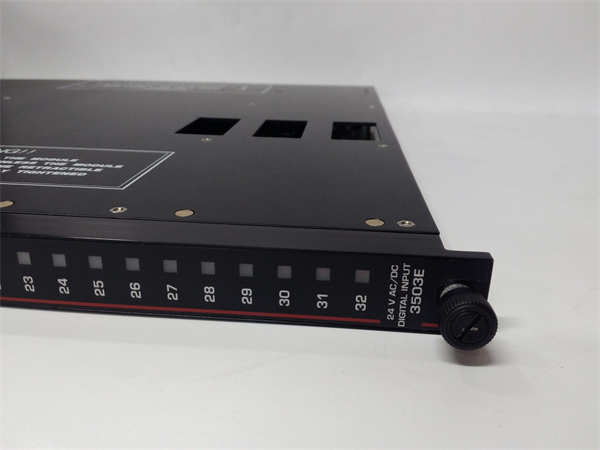

- Product Model: 3503E

- Manufacturer: Triconex (Schneider Electric)

- System Family: Tricon v9/v10 Safety Instrumented System (SIS)

- Input Channels: 8 independent TMR analog inputs

- Input Signal Range: 4–20 mA (standard), with support for 1–5 V DC via external shunt (field-configurable)

- Accuracy: ±0.1% of full scale at 25°C

- Isolation: Channel-to-channel and channel-to-backplane isolation rated per IEC 61010

- Diagnostic Coverage: >99% (aligned with IEC 61508 for SIL 3 applications)

- Redundancy Architecture: Full Triple-Modular Redundancy—each input signal is independently processed by three channels and voted

- Backplane Compatibility: Requires Tricon MP or XP main chassis with compatible I/O carrier

- Operating Temperature: 0°C to 60°C

- Certification: IEC 61508 SIL 3, ANSI/ISA 84.01, EN 61511

System Role and Downtime Impact

The 3503E serves as a primary interface for safety-critical analog process variables in Tricon-based Safety Instrumented Systems (SIS), widely used in refineries, chemical plants, and power facilities. It digitizes signals from transmitters monitoring parameters such as reactor pressure, turbine vibration, or boiler drum level—inputs directly tied to emergency shutdown (ESD) or trip logic. Due to its TMR architecture, a single channel fault is masked, but a second fault on the same input can cause a detected or undetected failure, potentially leading to loss of that safety function. Complete module failure severs all eight input paths, which may trigger a partial or full system trip depending on application design. In regulated environments, such an event can result in production loss, regulatory scrutiny, and extended downtime if a verified spare is not immediately available.

Reliability Analysis and Common Failure Modes

Despite its robust fault-tolerant design, the 3503E is vulnerable to age-related degradation after decades of continuous operation. The most common failure modes include drift in precision input amplifiers due to thermal stress, degradation of reference voltage sources affecting calibration stability, and corrosion of terminal blocks or backplane connectors in harsh industrial atmospheres. Electrolytic capacitors in local filtering circuits often dry out over time, causing intermittent signal noise or module reset. A key weakness is sensitivity to external wiring issues: ground loops, shield miswiring, or transient surges from nearby equipment can damage input protection diodes or op-amps. For maintenance personnel, recommended practices include performing annual full-loop calibrations with three-channel verification, inspecting terminal torque and oxidation, verifying proper single-point grounding of cable shields, and storing spares in static-dissipative, climate-controlled packaging to minimize component aging.

-

TRICONEX 3503E

Lifecycle Status and Migration Strategy

Schneider Electric has discontinued the 3503E as part of the broader obsolescence of Tricon v9/v10 hardware. No direct drop-in replacement exists in current Triconex offerings, and factory repair or technical support is no longer available. Continued reliance on this module carries increasing operational and compliance risk due to shrinking spare availability and lack of traceable calibration. As an interim measure, operators may establish strategic spares pools from functionally tested units or utilize certified third-party services for board-level rework (e.g., capacitor replacement, connector reflow). For long-term sustainability, Schneider recommends migrating to the Tricon CX or eXP platform. The functional successor is the AI-3503F or newer AI-3513 module, which maintains TMR architecture and SIL 3 certification but requires a new chassis, updated firmware, and re-validation of all safety logic in TriStation 1131. This migration is typically executed during major safety system upgrades or plant life-extension projects. Early assessment of I/O dependencies and spare inventory health is critical to avoid unplanned exposure due to component failure.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: