Description

Key Technical Specifications (For Spare Parts Verification)

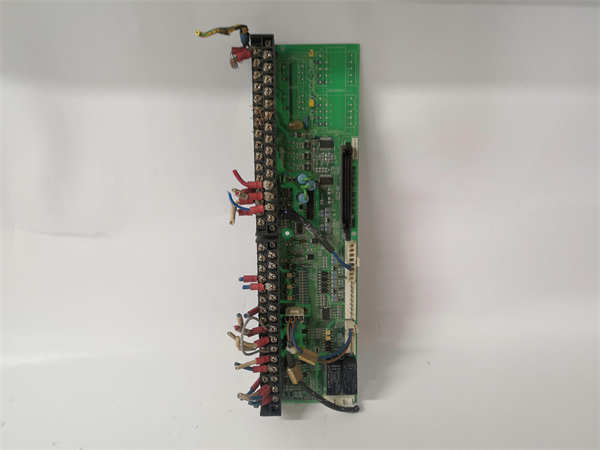

- Product Model: 2N3A3120-D

- Manufacturer: TOSHIBA

- System Platform: Used in legacy Toshiba FA (Factory Automation) systems, including EX-series PLCs and associated I/O racks

- Input Voltage: Typically 100–240 VAC (50/60 Hz) or 24–48 VDC (depending on variant—verify label)

- Output Voltage: 24 VDC (regulated)

- Output Current: Approximately 5 A (verify nameplate; common rating for this form factor)

- Efficiency: ~75–80% (typical for era)

- Protection Features: Overload, overvoltage, and short-circuit protection (auto-recovery type)

- Mounting: DIN rail or chassis-mounted with screw terminals

- Cooling Method: Convection-cooled (no fan)

- Operating Temperature: 0°C to +55°C

System Role and Downtime Impact

The 2N3A3120-D serves as a foundational power source in older Toshiba factory automation installations, commonly found in automotive assembly lines, packaging machinery, and material handling systems deployed in the 1990s–2000s. It supplies clean, regulated 24 VDC to PLC CPU units, digital I/O modules, and field sensors. In non-redundant configurations—which were standard at the time—a single power supply failure causes immediate and total shutdown of the controlled machine or cell. For example, in a robotic welding station, loss of this power module halts all motion, safety interlocks, and HMI communication, requiring manual intervention and potentially disrupting upstream/downstream processes. Given its age, many installed units are operating well beyond their design life, increasing the probability of sudden failure.

Reliability Analysis and Common Failure Modes

This generation of industrial power supplies is particularly vulnerable to component aging due to continuous operation under thermal stress:

- Electrolytic capacitor drying: The primary cause of failure. Capacitors in the input filter and output regulation stages lose capacitance over time, leading to output voltage ripple, instability, or complete dropout. Units in warm enclosures (>40°C) degrade faster.

- Switching transistor fatigue: The main power MOSFET or bipolar transistor in the converter stage can fail shorted due to thermal cycling, causing blown fuses or burnt PCB traces.

- Fanless thermal stress: Without active cooling, internal components operate at elevated temperatures, accelerating solder joint fatigue and semiconductor wear.

- Terminal block corrosion: Moisture or chemical exposure can corrode screw terminals, increasing contact resistance and causing localized heating or open circuits.

Recommended maintenance actions include:

- Measuring output ripple voltage annually with an oscilloscope (should be < 100 mVpp).

- Checking for bulging or leaking capacitors during visual inspections.

- Ensuring adequate ventilation around the power supply in the control cabinet.

- Replacing units proactively after 10–12 years of service, even if still functional.

TOSHIBA 2N3A3120-D

Lifecycle Status and Migration Strategy

Toshiba has discontinued the 2N3A3120-D and exited the general-purpose industrial power supply market for FA systems. No direct replacement is offered, and technical documentation is no longer publicly available. Continued use carries high operational risk due to zero OEM support and minimal verified spares.

Interim mitigation strategies:

- Source only from vendors who provide full load testing reports (including ripple, regulation, and protection trip verification).

- Maintain at least one tested spare per critical machine.

- Consider external redundant power architectures using modern DIN-rail PSUs to bypass reliance on the original unit.

Long-term migration path:

Since Toshiba no longer supports this platform, the most viable solution is to replace the entire power subsystem with a modern, certified DIN-rail power supply from a current manufacturer (e.g., Mean Well, Phoenix Contact, Weidmüller). A suitable replacement should meet:

- Same or higher output current (e.g., 24 VDC / 5–10 A)

- DIN rail mounting and comparable footprint

- Built-in protections (OCP, OVP, SCP)

- Higher efficiency (>85%) and longer MTBF

This approach requires rewiring but eliminates dependency on obsolete hardware. For facilities maintaining legacy Toshiba PLCs, this power upgrade can significantly extend system life without full controller replacement. However, given the age of the broader platform, a full migration to a modern automation system should be evaluated as part of long-term asset strategy.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: