Description

Technical Specifications (For Spare Part Verification)

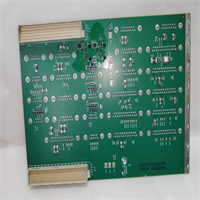

- Product Model: TPMC815-11

- Manufacturer: TEWS GmbH (legacy brand under Kontron Group)

- System Family: VME64x / CompactPCI ecosystem

- Form Factor: 6U VME single-slot carrier board

- PMC Slots: One PMC site compliant with IEEE P1386.1

- Bus Interface: VME64x (32-bit, 64-bit optional), supports 2eSST protocols

- Power Supply: +5V, ±12V via VME backplane; PMC power delivered per specification

- Operating Temperature: Typically 0°C to +60°C (commercial); extended variants may exist

- Mechanical Keying: Standard VME Eurocard with front panel I/O cutout support

- Firmware/BIOS: None (passive carrier); functionality defined by mounted PMC module

System Role and Downtime Impact

The TPMC815-11 functions as a critical bridge in legacy VME-based embedded control systems, commonly deployed in railway, defense, or industrial automation applications from the late 1990s to early 2010s. It does not process logic itself but enables high-functionality PMC modules—such as those handling real-time I/O, communication, or signal processing—to operate within a VME chassis. If this carrier fails (e.g., due to power regulation issues or connector damage), the attached PMC module becomes inoperable, potentially disabling safety-critical subsystems like train door control, data acquisition, or motion interfaces. In many installations, no hot-swap redundancy exists, meaning failure leads to unplanned downtime until replacement is sourced and installed.

Reliability Analysis and Common Failure Modes

Despite its passive design, the TPMC815-11 is susceptible to several aging-related failure mechanisms. The most common issues stem from electrolytic capacitors in the local power filtering circuitry drying out over time, leading to voltage instability for the PMC module. Additionally, repeated thermal cycling can cause micro-cracks in solder joints around the PMC connector or VME edge fingers, resulting in intermittent communication. The board’s reliance on mechanical retention screws and card guides also introduces risk: vibration in rail or mobile applications may loosen connections, causing signal integrity loss. Design-wise, the lack of overvoltage protection on the VME lines makes it vulnerable to power surges. For preventive maintenance, technicians should inspect for bulging capacitors, clean VME edge connectors with contact enhancer, verify secure mounting of the PMC module, and monitor system logs for bus errors that may indicate early carrier degradation.

TEWS TPMC815-11

Lifecycle Status and Migration Strategy

The TPMC815-11 has been officially discontinued following TEWS’ integration into MEN Mikro and later Kontron. No direct new-build replacements are offered, and original documentation is archived. Continued use carries significant risk: spare units are scarce, pricing on the secondary market is volatile, and technical support is limited to legacy case-by-case basis. As a temporary measure, facilities may consider board-level repair (e.g., capacitor rework) or sourcing tested surplus units with warranty. For long-term sustainability, migration to modern architectures is advised. Kontron recommends transitioning to VPX or CompactPCI Serial platforms, or using FPGA-based VME-to-PCIe bridge solutions. A practical path involves replacing the entire VME subrack with a contemporary embedded system (e.g., Kontron CP307 or similar) that emulates required I/O functionality, though this typically necessitates application software adaptation and revalidation—especially in safety-certified environments. Early planning for such migration is strongly encouraged to avoid operational disruption.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: