Description

Technical Specifications (For Spare Part Verification)

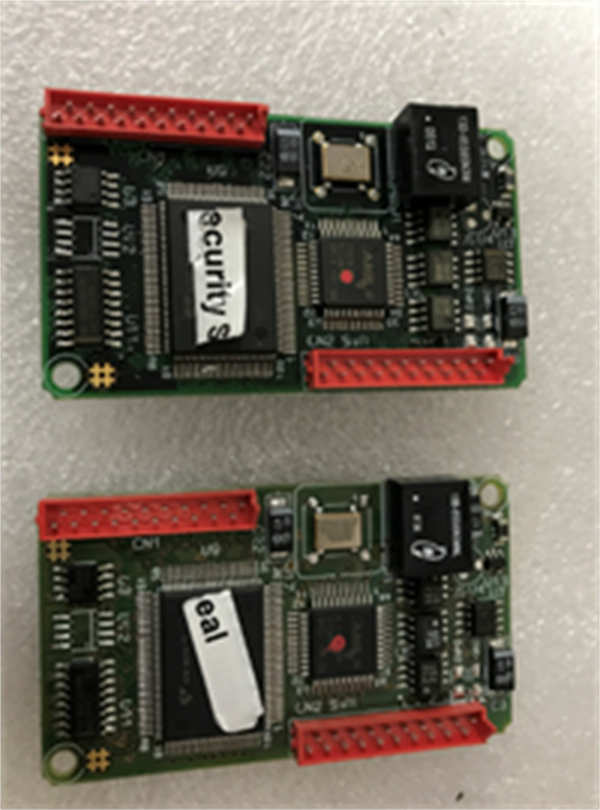

- Product Model: TCM08A

- Manufacturer: UNIOP S.p.A. (Parker Hannifin)

- System Platform: UNIOP eTOP series operator panels (e.g., ETV, ETG families)

- Module Type: Analog input expansion module (plug-in type)

- Input Channels: 8 differential inputs

- Supported Signal Types: Pt100 RTD, Ni100, thermocouples (J, K, T, etc.), 0–10 V, 0–20 mA, 4–20 mA

- Resolution: 16-bit A/D conversion

- Isolation: Channel-to-system isolation (typically 500 V DC)

- Communication Interface: Proprietary serial bus to main HMI CPU board

- Power Supply: +5 V / +24 V DC from host panel backplane

- Operating Temperature: 0°C to +50°C

- Physical Form: Compact plug-in card, often installed behind the HMI bezel; labeled “TCM08A” with version/date code

TCM08A UNIOP

System Role and Downtime Impact

The TCM08A serves as a dedicated analog signal acquisition module for UNIOP eTOP series human-machine interface (HMI) panels, commonly found in packaging machinery, food processing lines, small water treatment units, and OEM industrial equipment. Unlike standard HMIs that rely solely on PLC communication, UNIOP panels with TCM modules can read field sensors directly—enabling standalone monitoring or backup control without a separate controller.

If the TCM08A fails, all connected temperature or analog process values disappear from the HMI screen, even if the underlying machine is still running. In applications like pasteurization, boiler monitoring, or refrigeration, this loss of visibility can force operators to shut down the line for safety, as they cannot verify critical parameters. Because the module is integrated into the HMI unit, replacement often requires partial disassembly of the panel, increasing repair time. In systems where the HMI is the sole point of process observation, this single point of failure becomes operationally critical.

Reliability Analysis and Common Failure Modes

The TCM08A contains precision analog circuitry vulnerable to environmental and electrical stress over time. The most common failure mode is drift or saturation in the analog front-end, caused by aging operational amplifiers or reference voltage components. This leads to inaccurate readings—such as a fixed “–999” or “OL” display—even when sensors are functional.

Another frequent issue is power supply instability due to degraded internal capacitors. Since the module draws power directly from the HMI’s internal rails, any ripple or voltage drop can cause intermittent communication errors with the main CPU, resulting in “COMM ERROR” or complete module dropout.

The module is also sensitive to ground loops or EMI from nearby VFDs or solenoids, especially if shielded cabling was not used during installation. Over time, this noise can damage input protection diodes or corrupt A/D conversion results.

Recommended maintenance includes: verifying sensor readings against a calibrated handheld meter during routine checks; inspecting wiring for proper shielding and grounding; and ensuring the HMI cabinet is free of dust and moisture. Any spare TCM08A should be tested with known-good RTD and 4–20 mA signals before deployment.

TCM08A UNIOP

Lifecycle Status and Migration Strategy

UNIOP discontinued the TCM08A following its integration into Parker Hannifin, which shifted focus toward Ethernet-enabled HMIs and standardized I/O protocols. The module is no longer available through official distribution, and firmware support ended years ago. Continued use poses risks: spares are untested, counterfeit units may lack proper calibration, and compatibility with newer eTOP firmware versions is not guaranteed.

Short-term mitigation involves sourcing only units with verifiable provenance and performing full functional validation—including all supported sensor types—before acceptance.

For long-term reliability, migration to a modern architecture is advised. Parker now offers the Parker HMI Series (e.g., P3/P5 panels) with built-in high-resolution analog inputs or support for external I/O via Modbus TCP or CANopen. Alternatively, replacing the UNIOP panel with a standard HMI (e.g., from Siemens, Weintek, or Maple Systems) paired with a small PLC (e.g., Siemens LOGO!, Allen-Bradley Micro800) provides greater flexibility, cybersecurity, and spare parts availability. While this requires reprogramming the display logic, it eliminates dependence on obsolete proprietary modules and aligns the system with current industry standards. Planning this upgrade now reduces future operational risk and supports digital readiness initiatives.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: