Description

Key Technical Specifications (For Spare Parts Verification)

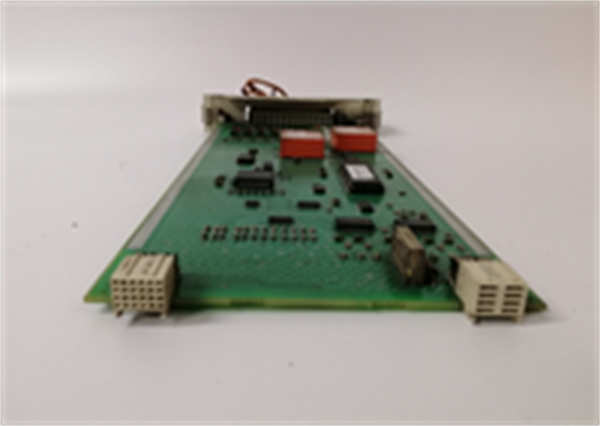

- Product Model: TC520 3BSE001449R1

- Manufacturer: ABB

- System Family: AC 800M (part of 800xA architecture)

- ABB Order Code: 3BSE001449R1

- Function: Termination unit for analog input modules (e.g., CI541, CI542)

- Mounting: DIN rail (TS-35) in I/O cabinets

- Connector Type: Screw-terminal blocks for field wiring (typically 2–4 mm² wire range)

- Backplane Interface: Proprietary connector to S800 I/O modules

- Power Supply: Passes 24 V DC and logic signals from module to field (no active electronics)

- Protection Rating: IP20 (requires cabinet mounting)

- Operating Temperature: 0°C to +55°C

System Role and Downtime Impact

The TC520 3BSE001449R1 serves as a passive but essential mechanical and electrical interface in ABB AC 800M I/O subsystems. It mounts on a DIN rail and accepts plug-in analog input modules (such as the CI541), providing a secure terminal block for field sensor wiring (e.g., 4–20 mA transmitters, RTDs). While it contains no active electronics, its integrity is vital: a cracked housing, corroded terminals, or damaged backplane connector can cause signal loss, measurement drift, or complete channel failure. In critical loops—such as boiler drum level, turbine vibration, or reactor temperature—this may trigger alarms, force manual control, or initiate safety shutdowns. Replacement requires de-energizing the I/O rack and re-terminating all field wires, leading to extended downtime if not planned.

Reliability Analysis and Common Failure Modes

Although the TC520 is a passive component, it is subject to environmental and mechanical stress over time. The most common issue is terminal block degradation, where repeated thermal cycling or improper torque causes loosening, oxidation, or arcing—especially in high-vibration areas. Second, plastic housing embrittlement occurs after prolonged exposure to heat or UV (if cabinet lighting is intense), leading to cracks that compromise module retention. Third, backplane connector wear from repeated module insertion/removal can result in poor contact, intermittent signals, or inability to seat the I/O module fully.

A key vulnerability is its reliance on proper installation practices; under-torqued terminals increase resistance, while over-torquing strips threads. Additionally, dust and moisture ingress in poorly sealed cabinets accelerate corrosion.

For preventive maintenance, inspect terminal tightness during scheduled outages using a calibrated torque screwdriver. Check for discoloration, pitting, or green corrosion on terminals. Verify that the module clicks securely into place with no wobble. Ensure cabinet environmental conditions (temperature, humidity) remain within specifications. Label all wires before removal to avoid cross-wiring during replacement.

TC520 3BSE001449R1 ABB

Lifecycle Status and Migration Strategy

ABB has discontinued the TC520 series as part of the broader phase-out of legacy S800 I/O hardware. No new units are produced, and official support is limited. Continued operation depends on existing inventory, which is increasingly scarce and expensive.

As a short-term measure, maintain verified spares for critical I/O racks. When replacing, ensure the spare matches the exact revision (3BSE001449R1), as terminal layout or connector pitch may vary across versions. Avoid mixing with non-ABB termination bases, as fit and signal integrity cannot be guaranteed.

For long-term sustainability, ABB’s migration path involves upgrading to the S800 I/O with modern termination units (e.g., TK51x/TK52x series) or transitioning to compact I/O platforms like AC 500 or Freelance for smaller applications. However, in existing AC 800M plants, the most practical approach is often to:

- Replace failed TC520 units with certified refurbished stock

- Implement wireless HART or IO-Link for non-critical analog points to reduce dependency on hardwired I/O

- Plan a phased I/O modernization during major turnarounds, aligning with controller and workstation upgrades

Given the passive nature of the TC520, third-party compatible bases may exist—but rigorous validation of electrical continuity, isolation, and mechanical fit is essential before deployment in safety-related or regulatory-monitored loops. Early engagement with an ABB-certified integrator is recommended to assess options and manage obsolescence risk effectively.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: