Description

Technical Specifications (For Spare Part Verification)

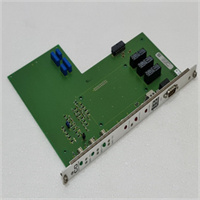

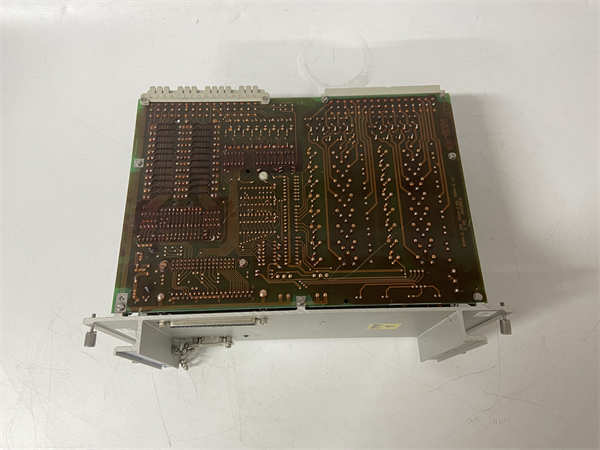

- Product Model: MERAK681K10078

- Manufacturer: SCHROFF (nVent SCHROFF GmbH)

- Series: MERAK 681

- Height: 3U (132.6 mm per IEC 297-3 / IEEE 1101.1)

- Width: Standard 19-inch rack width (~482.6 mm overall, with mounting flanges)

- Material: Steel or aluminum, typically with conductive coating (e.g., zinc-nickel or chromate-free passivation) for EMI shielding

- Finish: Often black textured powder coat or conductive paint

- Features:

- Integrated grounding points or EMI gaskets (depending on variant)

- Cutouts or blank surface (verify if this is a solid cover or has window/label area)

- Compatible with MERAK 681 chassis base (e.g., MERAK681Axxxx series)

- Mounting via captive screws or slide-in guides

- EMC Compliance: Designed to meet EN 55022 / FCC Class A when installed in complete subrack

- RoHS: Likely non-compliant (legacy product predating strict RoHS enforcement)

System Role and Operational Impact

The MERAK681K10078 is a mechanical enclosure component used in industrial control systems from the 1990s–2000s, commonly housing modules from vendors like Siemens, ABB, Bosch Rexroth, or proprietary OEM electronics in sectors such as rail, energy, and factory automation. While it contains no electronics, its absence or damage can lead to:

- Reduced EMI shielding, causing signal noise or communication errors in sensitive analog/digital circuits

- Ingress of dust or conductive debris, increasing risk of short circuits or thermal hotspots

- Non-compliance with safety inspections (e.g., during ISO or OSHA audits) due to open chassis

- Voided equipment warranties or certifications if original enclosure integrity is breached

In regulated environments (e.g., nuclear, rail, or oil & gas), missing front panels may constitute a reportable deviation.

Reliability and Common Issues

As a passive metal part, the MERAK681K10078 does not “fail” electronically, but common issues include:

- Corrosion or paint chipping in humid or chemically aggressive environments

- Stripped screw threads from repeated removal

- Bent mounting flanges due to mishandling

- Loss of EMI gasket conductivity over time (if equipped)

SCHROFF MERAK681K10078

Lifecycle Status and Replacement Strategy

SCHROFF discontinued the MERAK series in the early 2000s, shifting focus to standardized formats like CompactPCI, MicroTCA, and custom nVent solutions. The MERAK681K10078 is no longer listed in current catalogs.

Short-Term Options:

- Source NOS or used panels from industrial surplus vendors (e.g., World of Controls, Radwell, EU Automation)

- Verify dimensional compatibility using legacy SCHROFF datasheets (Document No. 84001-xxx series)

- Use generic 3U blank panels only if EMI shielding is not critical (not recommended for safety or high-noise systems)

Long-Term Strategy:

- Chassis migration: Replace entire MERAK subrack with a modern nVent or Rittal-compatible 19″ 3U solution

- Modular retrofit: Rehouse existing electronics into a new backplane-compatible enclosure (if PCB dimensions allow)

- Documentation update: Record panel status in asset management systems to flag non-conformities during audits

Cross-Reference & Documentation Tips

- Legacy SCHROFF Part Group: MERAK 681 = 3U subrack family; “K” prefix often indicates front panel variant

- Check Datasheet: Look for “MERAK 681 Montageanleitung” (assembly manual) or “Mechanical Drawing 84001-10078”

- Alternative Search Terms: “SCHROFF 681K10078”, “MERAK 3U front bezel”, “nVent obsolete MERAK panel”

While seemingly minor, maintaining full enclosure integrity is a key aspect of lifecycle management in industrial control systems—ensuring safety, compliance, and electromagnetic compatibility throughout the asset’s operational life.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: