Description

Technical Specifications (For Spare Parts Verification)

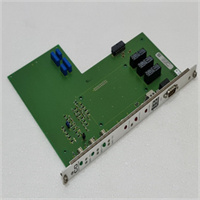

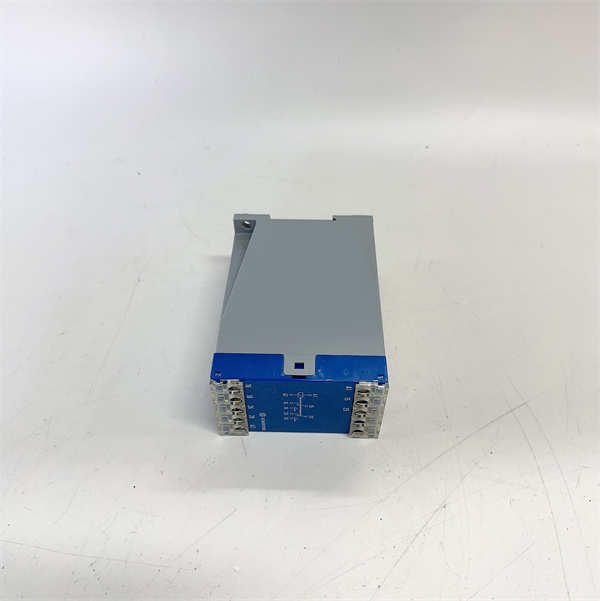

- Product Model: SSY52

- Manufacturer: SCHLEICHER

- Safety Standard Compliance: EN 954-1 Category 3, VDE 0113

- Input Channels: 2 independent safety inputs (for dual-channel devices like e-stops or door switches)

- Output Contacts: Force-guided (positively driven) relays, typically 3 NO + 1 NC or similar configuration

- Supply Voltage: 24 VDC (±10%)

- Response Time: ≤ 20 ms

- Reset Method: Manual or automatic (depending on wiring)

- Housing: DIN rail mountable, IP20 protection

- Certifications: CE, TÜV (original units only)

- Mechanical Life: ≥ 1 million operations

System Role and Downtime Impact

The SSY52 was widely deployed in European industrial machinery from the 1990s through the early 2000s as a compact, certified solution for basic safety circuits. It directly monitors emergency stop buttons, safety door interlocks, and other protective devices, cutting power to hazardous actuators (e.g., motors, hydraulics) upon fault detection. In these systems—often still in service due to robust mechanical design—the SSY52 acts as the sole safety logic unit. Its failure (e.g., welded contacts, input channel drift, or reset malfunction) can result in either dangerous undetected faults (no shutdown when required) or nuisance trips (unplanned downtime). Because modern safety standards (e.g., ISO 13849-1 PLr) require documented performance levels, continued use of uncertified or unverifiable SSY52 units may invalidate machine CE declarations.

Reliability Analysis and Common Failure Modes

Despite robust initial design, the SSY52 is now well beyond its intended service life. The primary failure mode is contact welding or sticking in the force-guided output relays, often caused by repeated switching under inductive loads without adequate suppression. This compromises the critical “positive opening” safety function.

Other common issues include:

- Capacitor aging in the internal power supply, leading to unstable operation or spontaneous resets

- Corrosion on terminal blocks, especially in humid or washdown environments, causing intermittent signal loss

- Degradation of internal optocouplers, resulting in reduced channel separation and potential cross-talk between safety inputs

A key vulnerability is the lack of self-diagnostics—the module provides no feedback on internal health beyond external LED indicators (which themselves can fail). Additionally, original TÜV certification data is rarely available with secondhand units, making compliance verification difficult.

Preventive maintenance guidance includes:

- Performing functional safety tests at regular intervals per local regulations (e.g., monthly e-stop test)

- Measuring contact resistance across output terminals during maintenance

- Ensuring all connected safety devices are properly wired in dual-channel configuration

- Maintaining at least one tested spare with traceable origin

SCHLEICHER SSY52

Lifecycle Status and Migration Strategy

SCHLEICHER has fully replaced the SSY series with its modern modular safety relay platform (e.g., SIRIUS 3SK1/3SK2 equivalents or SCHLEICHER’s own programmable safety controllers). The SSY52 has been obsolete for over a decade, with no official repair, recertification, or technical support available.

Short-term risk mitigation options include:

- Engaging certified safety integrators to validate existing units via functional testing

- Installing external monitoring relays to detect output contact welding (partial workaround)

- Sourcing NOS (New Old Stock) units with original packaging and certificates—though increasingly rare

For compliant, sustainable operation, direct replacement with a modern safety relay is necessary. Recommended equivalents include:

- SCHLEICHER SIRAX SR2 series (if staying within brand)

- Siemens 3SK1111-1AB20 (compact safety relay, Cat. 4 / PL e)

- Pilz PNOZ X2.8P (widely supported, global availability)

- Rockwell Guardmaster 440R-E2C200

These replacements offer enhanced diagnostics, configurable logic, and full compliance with ISO 13849-1. While wiring may require minor adaptation (e.g., different terminal layout), the physical footprint is often similar. Upgrading ensures ongoing regulatory compliance, reduces liability exposure, and aligns legacy equipment with current safety best practices.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: