Description

Technical Specifications (For Spare Part Verification)

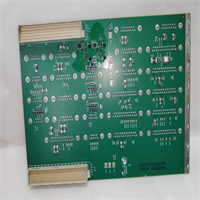

- Product Model: VIPC616

- Manufacturer: SBS (Schroff / SBS Technologies)

- Product Family: VIPC Series VME Power Supplies

- Form Factor: 6U x 160 mm (VME standard), single-slot width

- Input Voltage: 85–264 VAC universal input, 47–63 Hz

- Output Power: 200 W continuous

- Output Voltages: +5 V (20 A), +3.3 V (10 A), +12 V (5 A), -12 V (1 A)

- Efficiency: >75% typical

- Cooling: Conduction-cooled (no internal fan); relies on chassis airflow or cold plates

- Protection Features: Over-voltage, over-current, short-circuit, and thermal shutdown

- Compliance: VME64x (IEEE 1014), IEC 60950 safety, CE marked

- MTBF: >100,000 hours (per original datasheet)

System Role and Downtime Impact

The SBS VIPC616 is typically installed as the main or backup power supply in 6U VME chassis used in defense electronics, industrial automation, and scientific instrumentation. It powers critical components such as CPU boards, I/O controllers, and signal processing modules. Because many legacy VME systems were designed with minimal or no power redundancy, a single VIPC616 failure can bring an entire subsystem offline. In a naval combat system, for instance, this could disable a fire-control processor; in a particle accelerator control rack, it might halt beam diagnostics. Recovery time is often extended due to the difficulty in sourcing verified replacements, making this module a high-consequence single point of failure in aging infrastructure.

Reliability Analysis and Common Failure Modes

Although robustly built, the VIPC616 is susceptible to age-related degradation common in early-2000s power electronics. The most frequent failure mode is capacitor aging—particularly in the primary-side bulk capacitors and secondary-side filtering stages—leading to output ripple increase, voltage droop under load, or complete shutdown due to over-voltage protection triggering. The absence of a cooling fan improves reliability in dusty environments but also means heat buildup accelerates component wear if chassis ventilation is inadequate. Additionally, repeated thermal cycling can cause solder joint fatigue on high-current paths, resulting in intermittent connections. For preventive maintenance, operators should monitor output voltages quarterly using a calibrated multimeter, inspect for bulging capacitors during chassis servicing, and ensure ambient temperature remains below 55°C. Keeping a tested spare on-site is strongly recommended, as lead times for verified units can exceed 12 weeks.

VIPC616 SBS

Lifecycle Status and Migration Strategy

SBS discontinued the VIPC616 following industry-wide shifts away from VME toward VPX and CompactPCI Serial architectures. No direct drop-in replacement exists from Elma (current brand owner), though functionally equivalent modern VME power supplies are available from Artesyn, Cosel, and Elma’s own updated lines (e.g., Elma EVMPS200 series). However, these may differ in pinout, enable logic, or mechanical tolerances, requiring verification before installation. As an interim measure, qualified vendors offer board-level refurbishment—replacing all electrolytic capacitors, cleaning PCBs, and burn-in testing—to restore reliability. For long-term sustainability, organizations should consider a phased migration to a modern backplane standard, though this entails significant re-engineering of application hardware and software. A practical approach is to conduct a power supply audit across all VME assets, prioritize systems with no redundancy, and establish a strategic reserve of tested VIPC616 units to bridge the gap until full platform modernization is feasible.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: