Description

Key Technical Specifications (For Spare Part Verification)

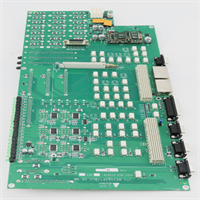

- Product Model: PCD4.D1XX

- Manufacturer: SAIA-Burgess Controls (now ABB)

- System Platform: SAIA PCD4 modular controller family

- SAIA Part Number: 463665500 (must match—other suffixes like D101/D116 may differ in voltage or isolation)

- Input Channels: 16 galvanically isolated digital inputs

- Input Voltage Range: Typically 24 VDC (nominal), with defined ON/OFF thresholds per IEC 61131-2 Type 1

- Isolation: Channel-to-backplane isolation (typically 500 VAC)

- Connection Type: Screw terminal block (removable)

- Diagnostic Features: Per-channel LED indicators for signal status

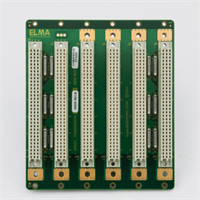

- Backplane Compatibility: Requires PCD4 base unit (e.g., PCD4.M1xx or PCD4.Rxxx rack)

- Firmware Dependency: None (passive I/O), but must be configured in PG5 programming environment

System Role and Downtime Impact

The PCD4.D1XX module is typically installed in control panels managing HVAC, water treatment, or small-scale industrial processes—common in European infrastructure due to SAIA’s strong regional presence. It acquires binary signals from field devices such as flow switches, door contacts, motor run feedback, or emergency stop circuits.

If this module fails—due to internal short, open circuit, or terminal corrosion—it results in:

- Loss of visibility into critical equipment status (e.g., “pump running” signal disappears);

- Potential disabling of safety interlocks or sequence logic (e.g., boiler won’t start without flame proof signal);

- False alarms or missed events in building management systems (BMS).

While not always causing immediate plant shutdown, its failure degrades system reliability and can violate operational or regulatory requirements (e.g., fire alarm supervision). In unattended remote stations, such faults may go undetected for extended periods.

Reliability Analysis and Common Failure Modes

Despite robust Swiss engineering, aging PCD4 modules exhibit predictable wear patterns:

- Common Failure Modes:

- Terminal block screw loosening over time due to thermal cycling, leading to intermittent signals;

- Input optocoupler degradation, causing delayed response or signal dropout at low voltage;

- PCB trace corrosion near terminals in humid environments;

- LED indicator burnout (non-critical but hampers troubleshooting).

- Design Weaknesses:

- Removable terminal blocks, while convenient, are prone to misalignment or poor contact if not torqued correctly;

- No built-in channel diagnostics beyond visual LEDs—no software fault reporting;

- Limited surge protection on inputs; vulnerable to induced transients from nearby inductive loads.

- Preventive Maintenance Recommendations:

- Tighten terminal screws during annual inspections using calibrated torque tool;

- Verify input signal integrity with a multimeter under loaded conditions;

- Inspect for discoloration or white powder (corrosion) around terminals in coastal or high-humidity sites;

- Keep spare modules powered periodically to prevent capacitor drying (if applicable).

-

SAIA PCD4.D1XX 463665500

Lifecycle Status and Migration Strategy

- Official Status and Risks:

ABB no longer manufactures or supports the PCD4 platform. Continued use entails:- Increasing difficulty sourcing matched spares;

- Incompatibility with modern cybersecurity and remote access standards;

- Lack of integration with current ABB engineering tools (e.g., Automation Builder).

- Interim Mitigation Measures:

- Secure 1–2 verified working spares and store them in dry, static-safe conditions;

- Use external relay isolation to protect inputs from field-side transients;

- Document wiring and I/O mapping thoroughly to accelerate replacement if needed.

- Migration Path:

ABB’s recommended migration path is to the AC 500 PLC platform (e.g., PM5xx CPU + DI524 digital input module), which offers:- Full compatibility with modern IEC 61131-3 programming in Automation Builder;

- Enhanced diagnostics, web server, and Ethernet connectivity;

- Long-term product lifecycle commitment.

Migration requires:

- Replacing the entire PCD4 rack with an AC 500 chassis;

- Rewiring field connections to new terminal layout;

- Converting or rewriting the application logic from PG5 to Automation Builder.

For cost-sensitive or small-scale applications, third-party retrofit solutions (e.g., Modbus RTU I/O gate

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: