Description

Key Technical Specifications (For Spare Parts Verification)

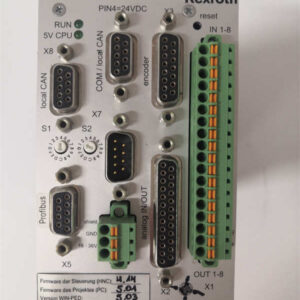

- Product Model: VTS0234-47 AP025

- Manufacturer: Bosch Rexroth AG

- System Platform: Custom or legacy hydraulic control system (often integrated with Indramat or early Rexroth valve manifolds)

- Input Signal: Typically ±10 VDC analog command from PLC or CNC controller

- Output Signal: Regulated current (e.g., 0–2 A) to proportional solenoid or torque motor

- Power Supply: 24 VDC (±10%) from machine control cabinet

- Mounting: DIN rail or panel-mounted near hydraulic manifold

- Feedback Compatibility: May support LVDT or pressure transducer feedback (depending on configuration)

- Environmental Rating: IP20 (indoor use only), operating temperature 0°C to +50°C

- Connector Type: Screw terminals or AMP/Harting-style plug (varies by build)

- Calibration: Factory-set gain/offset; often requires manual potentiometer adjustment during commissioning

System Role and Downtime Impact

The VTS0234-47 AP025 functions as the critical interface between a machine’s control logic and its hydraulic actuation system—commonly found in metal stamping presses, plastic injection molding machines, or test rigs requiring precise force or position control. It translates low-level voltage commands into high-fidelity current signals that drive proportional directional or pressure control valves. If this module fails, the associated hydraulic axis may stall, drift, oscillate uncontrollably, or default to a safe state (e.g., pressure dump). In cyclic production environments, even a partial performance degradation can cause part quality defects or trigger safety interlocks. Because this is not a standardized product, diagnostics are limited to basic voltage checks, and troubleshooting often requires deep system knowledge. Unplanned failure typically halts the entire machine until a verified replacement is installed, with downtime costs ranging from thousands to tens of thousands of dollars per hour depending on the application.

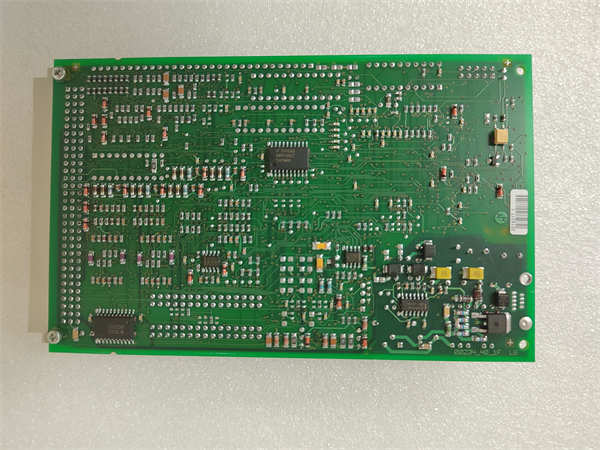

Reliability Analysis and Common Failure Modes

This module exhibits typical failure patterns of early-generation analog servo amplifiers. The most common issue is drift or total loss of output current due to aging operational amplifiers, failing power transistors, or degraded feedback resistors. Electrolytic capacitors in the power filtering and signal conditioning stages are prone to drying out after 10–15 years of service, leading to increased noise, thermal instability, or intermittent shutdowns. The unit’s reliance on mechanical potentiometers for calibration introduces another failure point—oxidation or mechanical wear can cause setpoint shifts during vibration-heavy operation. A key design limitation is the absence of digital communication or self-diagnostics; there is no status LED beyond basic power-on, and no fault logging capability. For preventive maintenance, technicians should periodically verify output current under simulated load, inspect for bulging capacitors or burnt components, clean potentiometer tracks with contact cleaner, and ensure secure mounting to minimize vibration-induced fatigue. Keeping a known-good spare powered in a test fixture with a dummy load can help detect latent failures before deployment.

VTS0234-47 AP025 REXROTH

Lifecycle Status and Migration Strategy

Bosch Rexroth does not list VTS0234-47 AP025 in any current or historical public catalog, indicating it was a custom-engineered solution for a specific OEM or end-user project. As such, it has no official successor, and factory support is unavailable. Continued operation carries significant risk: spare units are virtually unobtainable, counterfeit or mislabeled modules are prevalent in the secondary market, and internal schematics are not publicly accessible. Temporary measures include board-level repair by specialized electronics firms or reverse-engineering the input/output behavior to integrate a modern generic amplifier—but these require extensive validation. The sustainable path is migration to a current Rexroth platform. For new builds or major retrofits, the VT-MSPA2-2 series offers a flexible, programmable alternative with digital configuration, CANopen/Ethernet interfaces, and built-in diagnostics. It supports a wide range of valve types and can be calibrated via software rather than potentiometers. Integration requires re-wiring, re-parameterization, and possibly updating the machine controller’s output scaling—but eliminates long-term obsolescence risk and improves system maintainability. A feasibility study using the original machine documentation is strongly recommended before initiating replacement.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: