Description

Technical Specifications (For Spare Parts Verification)

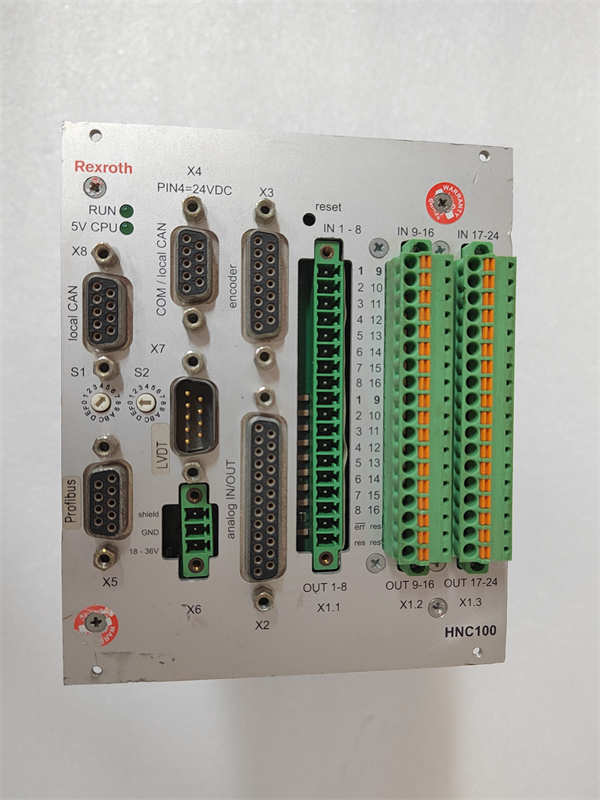

- Product Model: SYHNC100-NIB-2X W-24-P-D-E23-A012

- Manufacturer: Bosch Rexroth AG

- System Family: IndraControl S100 distributed I/O platform

- Communication Protocol: PROFIBUS DP (Slave device)

- Bus Connection: 9-pin D-SUB (RS-485), isolated

- Supported Baud Rates: 9.6 kbps to 12 Mbps (configurable via DIP switches or software)

- Power Supply: 24 VDC via backplane (from S100 base unit)

- Diagnostic Indicators: LED status for Power, Bus Communication, and Module Fault

- Mounting: Snap-in module for S100 terminal blocks (requires compatible base like SYHST100-…)

- Firmware Dependency: Requires matching GSD file in master PLC (e.g., Siemens, Allen-Bradley with PROFIBUS master)

System Role and Downtime Impact

This module functions as the communication backbone for IndraControl S100 remote I/O stations. It is typically installed in decentralized I/O cabinets near machines—common in printing, packaging, and material handling systems deployed in the 2000s. If this NIB (Network Interface Board) fails, the entire I/O station becomes unreachable by the central controller. This results in loss of digital and analog signals (e.g., sensor inputs, valve outputs), triggering safety stops or production halts. In a multi-station line, a single failed NIB can disable an entire machine zone, leading to unplanned downtime that may last hours or days if no verified spare is available.

Reliability Analysis and Common Failure Modes

The SYHNC100-NIB-2X was engineered for industrial environments but exhibits age-related vulnerabilities. The most frequent failure mode is communication dropout due to degraded RS-485 transceiver ICs, often accelerated by electrical noise or ground loops in legacy installations. A secondary issue is corrosion or oxidation on the D-SUB connector pins, especially in humid or washdown areas, causing intermittent bus errors. The module contains no user-serviceable components like batteries, but its reliance on stable 24 VDC makes it sensitive to power supply ripple or voltage sags—common in aging control panels. As a passive communication adapter with no moving parts, it generally operates reliably until environmental stress or component aging takes effect. For preventive maintenance, technicians should: (1) inspect and clean D-SUB connectors annually, (2) verify proper shielding and grounding of PROFIBUS cables, (3) monitor bus diagnostics in the PLC for cyclic redundancy errors, and (4) keep at least one tested spare on-site, stored in ESD-safe packaging.

REXROTH SYHNC100-NIB-2X W-24-P-D-E23-A012

Lifecycle Status and Migration Strategy

Bosch Rexroth officially discontinued the IndraControl S100 platform, including the SYHNC100-NIB series, with no direct replacement offered. Continued use carries substantial risk: no factory warranty, no technical support, and dwindling inventory driving up secondary-market prices. As a temporary measure, facilities can source tested units from specialized surplus suppliers or explore board-level repair services for units with isolated IC failures. However, the sustainable path is migration. Rexroth’s recommended upgrade is to the IndraControl VPPM or MLC platform, which uses EtherCAT or PROFINET instead of PROFIBUS. This transition requires replacing not only the NIB but also the entire I/O terminal block system and reconfiguring the PLC communication stack. While capital-intensive, such a migration eliminates single-point obsolescence risks and enables integration with modern SCADA and IIoT architectures. For budget-constrained operations, a phased approach—replacing one I/O station at a time during planned outages—is advisable.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: