Description

Key Technical Specifications (For Spare Verification)

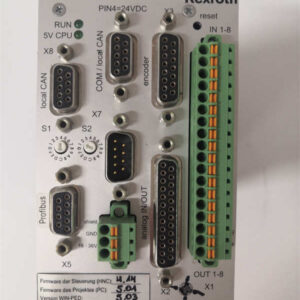

- Product Model: HCS01.1E-W0018-A-02-A-CC-EC-EC-NN-NN-FW

- Manufacturer: Bosch Rexroth

- Series: IndraDrive HCS (compact, non-modular variant)

- Order Number: R911342853

- Continuous Current Rating: 1.8 A RMS (as indicated by “W0018”)

- Peak Current: Typically 4.5 A (3x continuous)

- Supply Voltage: 240 VAC single-phase (standard for HCS01.1E)

- Motor Feedback Interface: EC (EnDat-compatible incremental encoder input)

- Communication Option: CC = CANopen master/slave (device-level network)

- Firmware Variant: FW (standard factory firmware)

- Cooling Method: Natural convection (no fan required at rated load)

- Mounting: DIN rail or panel mount with standard cutout

- Safety Functions: None integrated (basic model without STO)

System Role and Downtime Impact

The HCS01.1E drive is commonly found in mid-tier automation equipment installed between the late 2000s and early 2010s—particularly in packaging, printing, and small assembly systems. It directly interfaces with a servo motor to execute position, velocity, or torque commands from a higher-level controller (e.g., PLC via CANopen). Unlike modular IndraDrive systems, the HCS series integrates power and control electronics into a single sealed unit, making field repair impractical. If this drive fails—due to overcurrent, overheating, or feedback communication loss—the connected axis becomes inoperable. In synchronized multi-axis machines (e.g., form-fill-seal lines), this triggers a full stop, requiring manual reset and potentially causing product waste or mechanical jamming. Recovery depends entirely on spare availability, as reconfiguration or bypass is not feasible.

Reliability Analysis and Common Failure Modes

This generation of compact servo drives exhibits several age-related vulnerabilities:

- Electrolytic capacitor degradation: Input and DC bus capacitors dry out over time, reducing filtering capability and causing voltage instability under load—often manifesting as random “overvoltage” or “undervoltage” faults.

- Power semiconductor fatigue: Repeated thermal cycling stresses IGBT modules, leading to intermittent short circuits or open failures, especially if ambient temperature exceeds 45°C.

- Encoder interface sensitivity: The EC feedback circuit is vulnerable to ESD or cable-induced noise, resulting in “encoder error” faults even with a functional motor.

- Firmware corruption: Unexpected power loss during operation can corrupt parameter sets, causing the drive to enter a locked state requiring a full reload (if engineering access exists).

Preventive maintenance best practices include:

- Inspecting for bulging capacitors or burnt odor during routine cabinet checks.

- Verifying encoder cable shielding and grounding integrity.

- Monitoring drive temperature with infrared scans during peak operation.

- Maintaining a backup of drive parameters (via IndraWorks or Service Tool) if software access is still possible.

Lifecycle Status and Migration Strategy

Bosch Rexroth has discontinued the HCS01.1E series, replacing it with the more flexible and serviceable IndraDrive Cs or IndraDrive Mi platforms. No new units of R911342853 are produced, and official repair services are no longer offered.

As an interim measure, users should:

- Source at least one tested, functionally verified spare with matching order number and firmware.

- Avoid operating near maximum ambient temperature or continuous current limits.

- Isolate the drive from electrical noise sources (e.g., VFDs, contactors) using proper shielding.

The recommended migration path is replacement with an IndraDrive Cs CSM01.1C-SE03-MA-M1-M1-S1-S1 (or equivalent), which offers:

- Pin-compatible mounting in many cases (may require adapter plate).

- Support for EnDat, SSI, and incremental encoders.

- Integrated STO and EtherCAT communication.

- Configuration via IndraWorks DSC or newer Engineering Framework.

Migration requires re-parameterization and possibly minor wiring changes (e.g., 24 V enable signal), but retains compatibility with existing motors if feedback types match. Given the obsolescence and lack of repairability, proactive replacement during planned outages is strongly advised to mitigate unplanned downtime risk.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: