Description

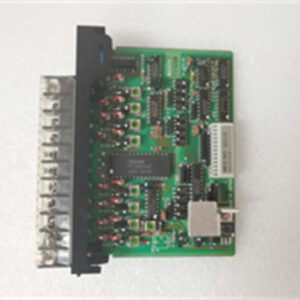

Key Technical Specifications (For Spare Part Verification)

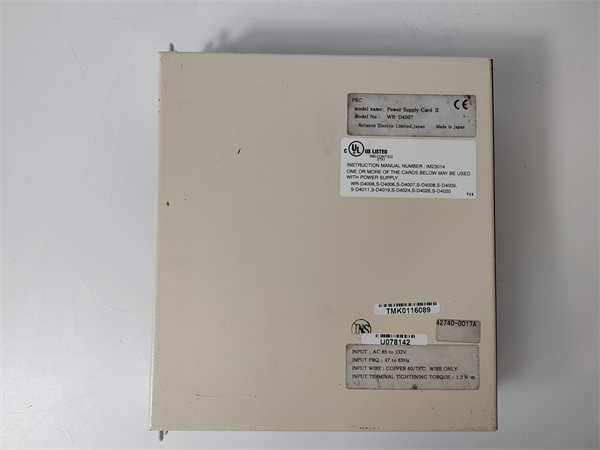

- Product Model: WR-D4007

- Manufacturer: Reliance Electric

- System Family: Reliance AutoMax / MaxPak DCS (pre-Rockwell integration era)

- Input Type: 16-channel isolated DC discrete inputs

- Input Voltage Range: 10–30 VDC

- Input Current: Approx. 4 mA per channel

- Isolation: Opto-isolated inputs with common return

- Backplane Compatibility: Requires specific AutoMax I/O chassis

- Diagnostic Features: Power OK LED; no per-channel diagnostics

- Operating Temperature: 0°C to 55°C

- Mounting: Slide-in module for standardized rack assembly

System Role and Downtime Impact

The WR-D4007 functions as a fundamental discrete input interface within Reliance AutoMax-based control systems, commonly deployed in water/wastewater, power, and light industrial applications during the 1980s–1990s. It reads binary status signals from field equipment such as motor starters, valve position indicators, and safety switches. Loss of this module—or failure of multiple channels—can lead to false alarms, inability to verify equipment state, or unintended disabling of interlocks. In safety-critical sequences (e.g., pump permissives or emergency shutdown logic), undetected input failure may compromise operational safety or trigger unnecessary plant trips, resulting in production loss or regulatory reporting events.

Reliability Analysis and Common Failure Modes

Although mechanically robust, the WR-D4007 is vulnerable to aging-related failures due to its decades-long service life. The most prevalent issues include optocoupler degradation—leading to intermittent or stuck input states—and corrosion on terminal blocks or backplane connectors caused by environmental humidity or chemical exposure. Power supply capacitors on the module’s internal circuitry may also dry out over time, causing voltage instability and erratic behavior during startup.

A notable design limitation is the absence of individual channel diagnostics; troubleshooting requires external loop testing or substitution. Additionally, the module lacks surge suppression on inputs, making it susceptible to damage from inductive kickback or ground potential differences if field wiring is not properly protected. Preventive maintenance should emphasize: (1) periodic continuity and insulation resistance checks on field wiring; (2) visual inspection of terminal tightness and signs of arcing; (3) cleaning of dust and conductive debris from module vents; and (4) functional validation during scheduled outages using simulated input signals.

Reliance WR-D4007

Lifecycle Status and Migration Strategy

Rockwell Automation discontinued support for the Reliance AutoMax platform years ago, and the WR-D4007 is no longer manufactured. Official repair services are unavailable, and technical documentation is scarce. Continued use relies entirely on dwindling surplus inventory, exposing facilities to extended downtime risk.

Interim strategies include sourcing tested units from decommissioned sites or employing third-party repair specialists for component-level fixes. However, these options offer diminishing returns as failure rates increase.

The sustainable path forward is migration to a modern Rockwell platform such as ControlLogix or CompactLogix. While not a direct replacement, equivalent functionality can be achieved using 1756-IB16 or 1769-IG16 discrete input modules. This transition requires re-engineering the I/O marshaling, updating control logic in Studio 5000, and re-commissioning affected loops. Although capital-intensive, migration enhances system reliability, enables remote diagnostics, and aligns with current cybersecurity and lifecycle management standards. A phased approach—starting with highest-risk or most critical I/O groups—is recommended to manage cost and operational impact.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: