Description

Key Technical Specifications (Based on Industry Norms for PT-VME330-Type Modules)

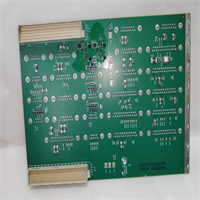

- Product Model: PT-VME330

- Bus Interface: VME64 (32-bit, 6U form factor)

- Analog Inputs: Typically 16 single-ended or 8 differential channels

- Resolution: 16-bit A/D conversion

- Input Range: Software-selectable (e.g., ±10 V, ±5 V, 0–10 V)

- Sampling Rate: Up to 100 kS/s (aggregate or per channel, depending on design)

- Isolation: May include channel-to-bus isolation (verify per unit)

- Triggering: Supports external/internal trigger for synchronized sampling

- Software Support: Legacy drivers for VxWorks, Linux (2.4/2.6), or Windows NT/XP via proprietary API

- Operating Temperature: 0°C to +55°C (commercial grade); extended temp versions rare

System Role and Downtime Impact

System Role and Downtime Impact

The PT-VME3330 (or PT-VME330) was commonly deployed in:

- Aerospace ground test equipment (engine monitoring, structural load testing)

- Power electronics R&D labs

- Nuclear or particle physics data acquisition systems

- Industrial automation retrofits using VME-based controllers

In these environments, the module serves as the “sensory nervous system,” converting real-world analog phenomena into digital data for control or analysis. A failed or drifting PT-VME330 can cause:

- False alarms or missed fault detection

- Inaccurate performance validation during certification tests

- Complete loss of data logging capability

- System shutdown if integrated into safety logic

Because VME systems are often custom-built and lack redundancy at the I/O level, a single card failure can halt an entire operation—especially in regulated industries where requalification is costly.

Reliability Analysis and Common Failure Modes

Despite robust construction, aging VME modules like the PT-VME330 suffer from:

- A/D converter drift: Due to reference voltage instability or aging precision resistors

- Capacitor degradation: Electrolytic capacitors in power filtering dry out, causing noise or reset loops

- Connector fatigue: P0/P1 VME connectors develop intermittent faults from thermal cycling or repeated chassis insertion

- Firmware corruption: If using flash-based configuration storage (rare but possible)

- Obsolescence-induced handling errors: Technicians unfamiliar with VME may misconfigure jumper settings or apply incorrect power

Preventive maintenance should include:

- Periodic calibration against traceable standards

- Visual inspection for PCB discoloration, capacitor bulging, or solder cracks

- Functional testing under simulated load using known signal sources

- Archiving original driver software and configuration files

Lifecycle Status and Migration Strategy

The PT-VME330 is firmly obsolete:

- No known manufacturer support (PTVME appears defunct or absorbed)

- VME technology itself is legacy; modern systems use PCIe, PXIe, or Ethernet-based DAQ

- Drivers incompatible with modern OS kernels or security policies

Short-term mitigation:

- Source used units from industrial surplus brokers (e.g., eBay, LabX, certified resellers)

- Use third-party reverse-engineering services to clone functionality (high cost, long lead time)

- Implement external signal buffering to reduce stress on existing modules

Long-term strategic path:

- Migrate to modern DAQ platforms:

- NI PXIe-449x series (for high-channel-count precision acquisition)

- ADLINK PCIe-9800 or USB-2400 series (for flexible I/O)

- Spectrum Instrumentation M2i/M4i cards (for ultra-high-speed applications)

- Requires:

- Rewriting application software (LabVIEW, C++, Python)

- Re-engineering chassis and cabling

- Re-validating measurement accuracy and timing

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp:  System Role and Downtime Impact

System Role and Downtime Impact