Description

Key Technical Specifications

- Product Model: MVI56E-MCM

- Manufacturer: ProSoft Technology (a Rockwell Automation Encompass Partner)

- System Family: ControlLogix 5000 Series Communication Modules

- Backplane Interface: Compatible with all ControlLogix 5-slot and larger chassis

- Serial Port: Isolated RS-232/422/485 (software-selectable), up to 115.2 kbps

- Ethernet Port: 10/100 Mbps, supports Modbus TCP client/server

- Supported Protocols: Modbus RTU, Modbus ASCII, Modbus TCP (simultaneous on both ports)

- Data Mapping: Direct read/write to ControlLogix tags via Produced/Consumed or explicit messaging

- Configuration Tool: ProSoft Configuration Builder (free, Windows-based)

- Power Consumption: 1.2 A @ 5.1 V DC (backplane supplied)

Core Performance and Selection Advantages

The ProSoft MVI56E-MCM offers significant engineering and operational advantages for new ControlLogix-based projects that require reliable, high-throughput Modbus integration. Unlike software-based Modbus solutions that consume PLC scan time or require custom ladder logic, the MVI56E-MCM operates as an autonomous co-processor—handling all protocol timing, retries, and data buffering independently. This offloads the main CPU, preserving scan performance for critical control tasks.

Compared to older single-port modules (e.g., MVI56-MCM), the “E” variant adds a dedicated Ethernet port for Modbus TCP, enabling simultaneous communication with serial field devices (e.g., flow meters over RS-485) and IP-based systems (e.g., SCADA historians or HMI servers). This dual-path capability eliminates the need for external protocol converters or additional network infrastructure, reducing both hardware count and points of failure.

From a total cost of ownership (TCO) standpoint, the module accelerates commissioning through its intuitive configuration utility, which auto-generates tag databases and validates device addressing before deployment. Because data appears directly in the controller’s I/O image, no explicit messaging or complex GSV/SSV instructions are needed for standard polling—a major reduction in programming effort. Furthermore, its native ControlLogix form factor ensures seamless support in Rockwell’s Studio 5000 environment, including EDS file integration, online diagnostics, and firmware updates via RSLinx.

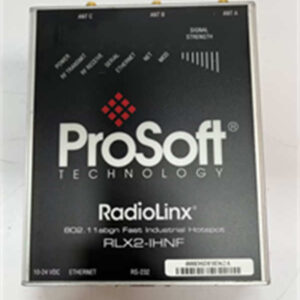

PROSOFT MVI56E-MCM

System Integration and Expandability

Integration begins within Rockwell’s Studio 5000 Logix Designer environment. The MVI56E-MCM is added to the I/O configuration tree like any standard module, with full EDS support enabling automatic parameter import. ProSoft’s free Configuration Builder tool connects to the module via the backplane (no separate USB or serial cable required) to define Modbus maps, poll rates, and error handling—all without interrupting the PLC program.

On the network side, the module supports concurrent Modbus RTU (over isolated serial) and Modbus TCP (over Ethernet), allowing it to bridge legacy serial devices into modern IP-centric architectures. It can act as a Modbus TCP server, enabling SCADA systems (e.g., Ignition, WinCC) to pull data directly without involving the PLC application logic. For cloud or IIoT use cases, the Ethernet port can feed data to edge gateways supporting OPC UA or MQTT, facilitating secure data flow to analytics platforms.

In terms of scalability, multiple MVI56E-MCM modules can coexist in a single chassis to support dozens of Modbus devices across independent networks—ideal for large pump stations or distributed energy sites. The module also supports redundancy when used in a ControlLogix redundant system (with appropriate firmware), ensuring continuous communication during controller switchover. Its modular design means future expansion (e.g., adding a second serial network) requires only slot availability—no re-architecture of the control strategy or network topology.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: