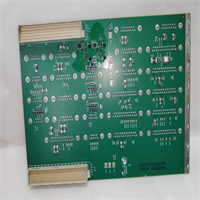

Description

Key Technical Specifications (For Spare Parts Verification)

- Product Model: SCE904AN-002-01

- Manufacturer: PACIFIC

- System Platform: Standalone or OEM-integrated analog I/O subsystem (commonly used in 1990s–2000s process control retrofits)

- Input Channels: 4 isolated channels

- Input Range: Configurable for 4–20 mA (loop-powered) or 0–10 V DC

- Accuracy: Typically ±0.1% of full scale (verify per unit calibration tag)

- Isolation: Channel-to-channel and channel-to-bus isolation (usually >500 VDC)

- Power Requirement: +24 VDC (±10%), supplied via backplane or terminal block

- Output Interface: Parallel digital bus or discrete voltage levels compatible with legacy CPU cards (exact protocol varies by system integrator)

- Mounting: DIN rail or panel mount with screw terminals

- Physical Labeling: Must include “SCE904AN-002-01” and revision code; absence suggests non-original replacement

System Role and Downtime Impact

The SCE904AN-002-01 functions as a foundational data acquisition component in older distributed control or programmable logic systems where modular I/O was not standardized. It is typically installed in remote I/O cabinets near process skids or in central control rooms, converting analog sensor outputs into digital values readable by a master controller—often a custom-built or proprietary CPU. Because these modules were frequently embedded in turnkey systems by engineering contractors, documentation is sparse, and replacements are not plug-compatible with modern platforms. If this module fails, the control system loses visibility into up to four critical process variables. In applications such as boiler drum level monitoring, reactor temperature control, or compressor suction pressure, this can force operators into manual mode or trigger safety shutdowns, leading to production loss, product quality deviation, or regulatory reporting events.

Reliability Analysis and Common Failure Modes

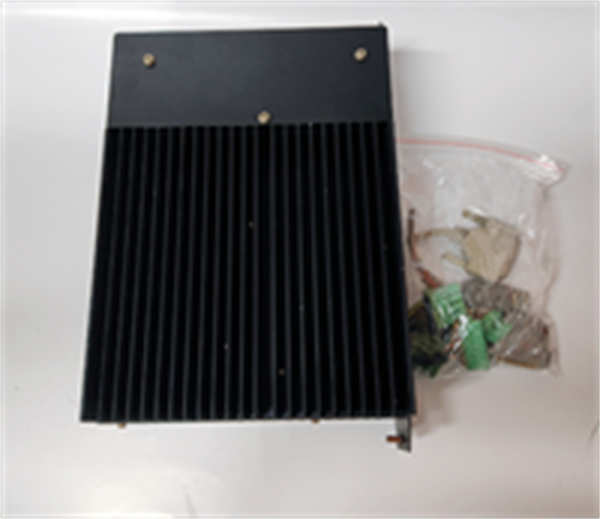

Despite its passive appearance, the SCE904AN-002-01 contains precision analog components vulnerable to long-term stress. The most common failure mode is drift in the input conditioning circuitry—particularly in the operational amplifiers and reference voltage sources—causing inaccurate scaling (e.g., 12 mA reads as 11.8 mA). Electrolytic capacitors on the power supply section degrade over time, especially in high-temperature enclosures, leading to intermittent operation or complete power dropout. Terminal blocks may suffer from galvanic corrosion when dissimilar metals (e.g., copper wire in brass clamp) are exposed to humid or chemical-laden atmospheres, increasing contact resistance and inducing signal noise. Additionally, the module’s lack of modern surge protection makes it susceptible to damage from lightning-induced transients or switching spikes on field wiring.

Preventive maintenance should focus on periodic calibration verification using a precision current source, thermal imaging of the module during peak load to detect hot spots, and torque checks on field wiring terminals. Since many units lack status LEDs, functional testing requires injecting known signals and validating output at the controller level. Keeping spare modules powered in a test rack can help identify latent failures before deployment.

SCE904AN-002-01 PACIFIC

Lifecycle Status and Migration Strategy

PACIFIC ceased production of the SCE904AN series well over a decade ago, and technical documentation is no longer available through official channels. Continuing to operate systems dependent on this module carries substantial risk: verified spares are scarce, pricing is unpredictable, and counterfeit units may use substandard components that fail prematurely.

Short-term mitigation includes sourcing tested units from specialized obsolescence management vendors, performing board-level repair (e.g., capacitor replacement), or implementing external signal duplication to reduce single-point failure impact. However, these approaches do not address the underlying architectural fragility.

A sustainable migration path involves replacing the entire I/O layer with a modern, open-platform solution. Suitable alternatives include:

- Analog Devices or Texas Instruments-based custom I/O (for embedded retrofits)

- Phoenix Contact AXC F 1152 with AI modules (supports PROFINET and Modbus TCP)

- WAGO 750-8101 PLC with 750-464 4-channel AI modules (cost-effective for small I/O counts)

Migration requires re-engineering the field wiring interface, updating control logic to read new I/O addresses, and re-commissioning loop calibrations. While this demands upfront engineering effort, it eliminates long-term obsolescence risk, improves diagnostic visibility, and enables integration with modern SCADA and IIoT platforms. For facilities unable to justify full replacement, maintaining a minimum of two verified spare SCE904AN-002-01 modules—each functionally tested within the last 12 months—is the only practical contingency.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: