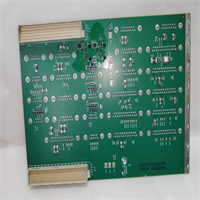

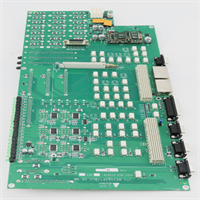

Description

Key Technical Specifications (For Spare Part Verification)

- Base Model: ND32-5610

- Full Order Code: ND32-5610VS-101-011-31

- VS: Voltage Sensing input type

- 101: Input voltage range (typically 110–250 V AC/DC)

- 011: Output interface (e.g., opto-isolated transistor or relay)

- 31: Mechanical/hardware revision or mounting variant

- Channels: Likely 8 or 16 isolated digital inputs (exact count requires physical verification)

- Input Type: Voltage-sensing (not dry contact); designed to detect presence/absence of control voltage (e.g., 125 V DC tripping circuits)

- Input Voltage Range: Commonly 88–265 V AC/DC (universal)

- Isolation: Galvanic isolation per channel (typically ≥2.5 kV)

- Output Interface: Optocoupled logic signals compatible with 24 V PLC inputs or proprietary backplane

- Mounting: DIN rail or panel-mount with screw terminals

- Indicators: LED per channel (ON/OFF status)

- Standards Compliance: Designed to meet IEC 60255 (for relay applications) and EN 50178 (industrial electronics)

-

NOVOTRON ND32-5610 ND32-5610VS-101-011-31

System Role and Downtime Impact

The ND32-5610 was commonly integrated into custom-built protection, monitoring, or sequencing panels for hydroelectric plants, substations, and industrial power systems—often interfacing between high-voltage switchgear and logic controllers (e.g., Siemens S5, ABB Master, or relay-based schemes).

Its role includes:

- Monitoring circuit breaker “Closed”/“Open” status via auxiliary contacts energized by control voltage

- Detecting alarm conditions from protective relays (e.g., 86 lockout, 50N ground fault)

- Providing interlock feedback for motor starters or transfer switches

Failure modes can lead to:

- False “healthy” indications during actual faults

- Inability to initiate automatic sequences (e.g., backup generator start)

- Violation of safety interlocks, risking equipment damage or personnel hazard

Because these modules were rarely redundant, a single failure can compromise system integrity—especially in unattended or remote facilities.

Reliability Analysis and Common Failure Modes

Despite robust Scandinavian design, aging units exhibit:

- Optocoupler degradation: Reduced CTR (current transfer ratio) causes missed signal detection

- Input resistor drift: High-value input resistors age under continuous voltage stress, altering threshold sensitivity

- LED indicator burnout: Visual status loss (non-critical but complicates troubleshooting)

- Terminal block corrosion: Especially in humid or coastal environments

- PCB delamination or trace cracking: From thermal cycling over decades of service

Preventive actions:

- Perform functional tests using simulated control voltage

- Measure input current draw to verify resistor network health

- Inspect for discoloration or capacitor leakage (if any filtering caps present)

- Maintain detailed photos and wiring records for reverse-engineering if needed

NOVOTRON ND32-5610 ND32-5610VS-101-011-31

Lifecycle Status and Migration Strategy

Novotron Electronics AB is defunct, and all ND32-series products are unsupported and unobtainable new. No direct replacements exist from the original manufacturer.

Short-term mitigation:

- Search specialized European industrial surplus markets (e.g., Sweden, Germany) for used units

- Consider third-party reverse-engineered equivalents (rare but occasionally available)

- Implement external monitoring (e.g., auxiliary relays + modern DI modules) as a bypass

Long-term strategic path:

Replace the entire I/O subsystem with a modern, supported platform such as:

- Phoenix Contact AXC F 1152 (with inline I/O)

- WAGO 750 Series modular I/O

- Siemens SIMATIC ET 200SP

- ABB AC500 or AC800M with TU85x I/O

Migration steps include:

- Mapping each ND32-5610 input to a new digital input channel

- Rewiring field signals (often reusing existing multicore cables)

- Updating logic in the replacement controller

- Validating all interlocks and alarms per IEC 61511 or site safety procedures

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: