Description

Technical Specifications (For Spare Part Verification)

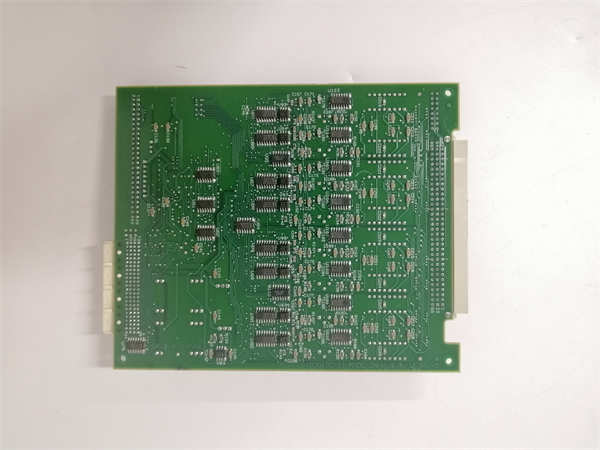

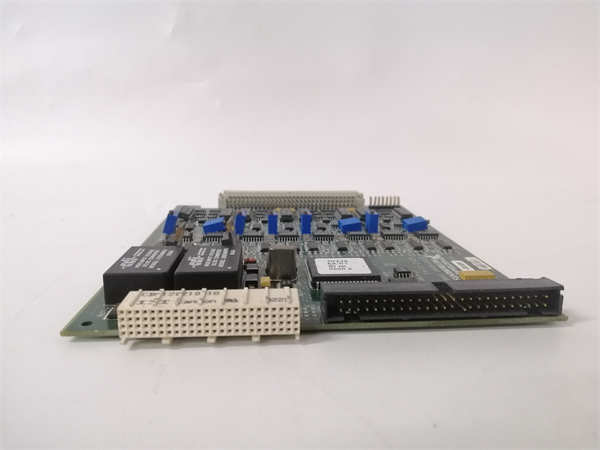

- Product Model: SCXI-1141

- Manufacturer: National Instruments

- Platform: SCXI (Signal Conditioning eXtensions for Instrumentation)

- Channels: 8 single-ended or 4 differential inputs

- Filter Type: 8-pole elliptic low-pass (anti-aliasing)

- Cutoff Frequency: Programmable from 1 Hz to 100 kHz (software-selectable)

- Input Range: ±10 V

- Overvoltage Protection: ±42 V continuous

- Output Impedance: <1 Ω (buffered)

- Compatibility: Works with SCXI-1000/1001 chassis and DAQ boards like NI 6052E, 6071E

- Software Support: Requires NI-DAQmx or Traditional NI-DAQ (legacy); not supported in modern LabVIEW versions without compatibility layers

- Physical Form: Full-size SCXI module (229 mm H × 58 mm W × 236 mm D)

System Role and Downtime Impact

The SCXI-1141 sits between field sensors (e.g., accelerometers, strain gauges, or voltage transducers) and the data acquisition hardware. Its primary role is to remove high-frequency noise and prevent aliasing during analog-to-digital conversion—critical in dynamic testing such as vibration analysis, structural health monitoring, or power quality measurement.

If the module fails—due to filter capacitor drift, op-amp degradation, or connector corrosion—it can cause:

- Aliasing artifacts that corrupt frequency-domain analysis (e.g., false peaks in FFTs)

- Signal clipping or distortion due to improper gain/buffering

- Complete channel dropout, leading to invalid test results or aborted experiments

In aerospace, automotive, or energy R&D labs, this can invalidate days of test data, delay certification cycles, or require costly retesting. Recovery involves sourcing a verified spare, recalibrating the entire channel chain, and revalidating measurement uncertainty budgets.

Reliability Analysis and Common Failure Modes

After 10–20 years of service, the SCXI-1141 commonly suffers from:

- Electrolytic capacitor aging in the power supply section, causing ripple on internal rails and unstable filter response

- Op-amp parameter drift, leading to gain errors or reduced bandwidth

- Backplane connector oxidation, resulting in intermittent contact or crosstalk between channels

- Relay wear (used for range switching), causing stuck states or increased contact resistance

Notably, the module lacks self-diagnostics—failures are often only detected during calibration or when data anomalies appear. Environmental stress (high temperature, humidity, or vibration) accelerates these mechanisms.

For preventive maintenance, users should:

- Perform annual end-to-end calibration using a precision signal generator and DAQ reference

- Inspect and clean SCXI backplane connectors with contact enhancer spray

- Store spares in climate-controlled conditions with periodic power cycling (every 12 months)

- Avoid operating near the 100 kHz cutoff limit, as aging components may not meet specs at high frequencies

SCXI-1141 182610D-01

Lifecycle Status and Migration Strategy

NI offers no direct replacement for the SCXI-1141. The strategic migration path is to modern PXI or CompactDAQ platforms:

- PXIe-449x series (e.g., PXIe-4499): 8-channel dynamic signal analyzers with built-in anti-aliasing, IEPE support, and 204.8 kS/s per channel

- NI 9234 (CompactDAQ): 4-channel IEPE/AC-coupled module with 51.2 kS/s and integrated filtering

Migration requires:

- Replacing SCXI chassis with PXIe or cDAQ chassis

- Rewiring sensor connections (BNC or LEMO instead of SCXI screw terminals)

- Updating LabVIEW code to use modern DAQmx APIs

- Revalidating all test procedures for accuracy and timing

While capital-intensive, this transition restores access to firmware updates, factory calibration, and long-term support. For facilities unable to migrate immediately, securing 1–2 tested SCXI-1141 spares from certified vendors—with full frequency response validation—is essential to bridge the gap until system retirement.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: