Description

Technical Specifications (For Spare Verification)

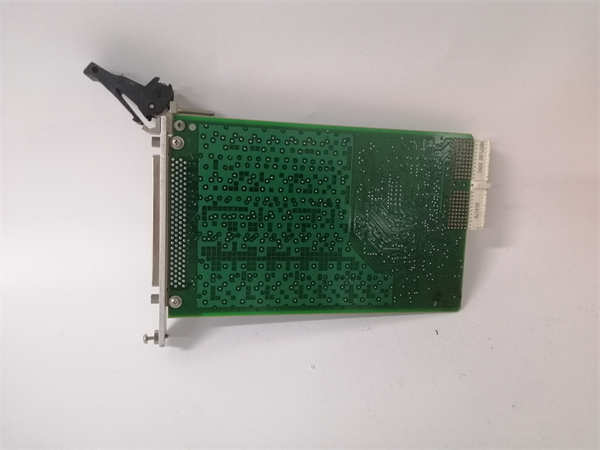

- Product Model: PXI-6527

- Manufacturer: National Instruments

- Platform: 3U PXI (32-bit, 33 MHz PCI interface)

- Channels: 48 bidirectional digital lines (configurable in 8-bit ports)

- Isolation: 250 Vrms continuous, channel-to-PXI backplane

- Input Voltage Range: ±5 V to ±60 V (user-selectable via jumpers)

- Output Drive Capability: Up to 150 mA per channel (sink), open-collector

- Logic Levels: TTL-compatible inputs; open-collector outputs with external pull-up

- Protection: Optical isolation, transient suppression, reverse polarity protection

- Connector: Two 50-pin SCSI-II (HD50) connectors (via breakout cables like CB-50LP)

- Software Support: Traditional NI-DAQ (legacy), limited NI-DAQmx support (requires compatibility mode)

- Max Switching Frequency: ~10 kHz (limited by optocoupler speed)

- Certifications: CE, FCC, CSA, RoHS

System Role and Downtime Impact

The PXI-6527 typically serves as the electrical interface between a PXI-based test executive and industrial field devices, such as:

- Energizing/de-energizing safety relays

- Simulating PLC discrete outputs

- Reading status from high-side switched sensors

- Controlling power sequencing in burn-in racks

Because of its high-voltage isolation, it protects the sensitive PXI chassis from ground loops, surges, or miswiring in factory-floor environments.

Failure modes include:

- Stuck-on/stuck-off outputs due to optocoupler or transistor degradation → unintended device activation or missed shutdown commands

- Loss of isolation → risk of backplane damage or system-wide fault

- Intermittent channels from connector wear → erratic test results or false pass/fail outcomes

Reliability Analysis and Common Failure Modes

After 10–15+ years of service, the PXI-6527 is prone to:

- Optocoupler LED aging: Reduced current transfer ratio (CTR) leads to slow rise/fall times or incomplete switching

- Output transistor wear: Especially in high-current sink applications (e.g., driving relay coils), causing thermal runaway

- Jumper misconfiguration or corrosion: Field-configurable voltage ranges rely on internal jumpers that can oxidize or shift

- SCSI connector fatigue: Repeated mating cycles degrade contact integrity, increasing resistance

The module lacks real-time diagnostics—failures are often discovered only during system checkout or through downstream device anomalies.

Preventive Maintenance Recommendations:

- Perform annual continuity and isolation tests using a megohmmeter

- Measure output sink voltage drop under load (should be <1 V at 100 mA)

- Inspect and clean HD50 connectors with contact enhancer

- Avoid operating near 60 V or 150 mA limits to extend component life

PXI-6527 185633D-01

Lifecycle Status and Migration Strategy

NI offers no direct PXI replacement for the PXI-6527. The strategic migration path depends on system architecture:

Option 1: PXIe-Based Replacement

- NI PXIe-6535: 32-channel, 3.3 V/TTL, non-isolated (not suitable for high-voltage)

- NI PXIe-6544: 32-channel, programmable logic levels, but still low-voltage

→ Not functionally equivalent for high-voltage switching

Option 2: External Isolation + Standard DIO

Use a modern PXIe DIO module (e.g., PXIe-6536) paired with an external opto-isolator or solid-state relay rack (e.g., from Opto22 or Crydom). This replicates functionality but increases wiring complexity and footprint.

Option 3: CompactDAQ Alternative

- NI 9403 (C Series): 32-channel bidirectional DIO, but only ±30 V tolerant

- NI 9476/9477: High-side/low-side switch modules (up to 60 V, 1 A) — closer match

→ Requires migration to cDAQ platform and LabVIEW re-engineering

Interim Risk Mitigation

For sites still dependent on PXI-6527:

- Secure 2–3 tested spares from reputable vendors with full channel validation reports

- Document jumper settings and cable pinouts for rapid swap-out

- Implement software-level heartbeat checks (toggle known-good channel and verify response)

Conclusion

While the PXI-6527 was a robust solution for industrial digital I/O in its era, its obsolescence presents growing operational risk. Facilities relying on it should prioritize spare acquisition now and develop a migration roadmap to either external isolated switching or newer NI platforms. Continuing operation without contingency planning exposes systems to extended downtime and potential safety compromises due to undetected I/O faults.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: