Description

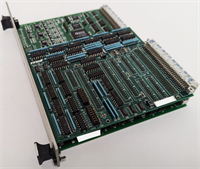

Technical Specifications (For Spare Part Verification)

- Model: FC-9821KE

- Manufacturer: NEC Corporation

- System Family: NEC EYIS (Engineering Yard Information System) and NDX Process Control Platforms

- Form Factor: Floor-standing or console-mounted industrial workstation with integrated 19″ monochrome CRT

- Processor: Intel i486 or early Pentium-class CPU (varies by revision)

- Operating System: Proprietary real-time OS or customized UNIX variant

- Display: Monochrome CRT, typically 1024×768 resolution, P39 phosphor

- Interfaces: RS-232/422 serial ports, proprietary NDX bus connection, PS/2 keyboard/mouse

- Power Supply: 100–240 V AC, internal linear or early switching PSU

- Cooling: Forced-air ventilation with replaceable filters

- Diagnostic Indicators: Power LED, HDD activity light, CRT degauss status

System Role and Downtime Impact

The NEC FC-9821KE is not merely a display—it is an integrated control terminal that runs the core HMI application for NEC’s EYIS and NDX systems, commonly deployed in Japanese and Asian power plants, steel mills, and municipal utilities from the 1980s through early 2000s. It provides operators with real-time mimic diagrams, alarm lists, trend data, and manual override capabilities. Because these systems often lack redundant HMIs or modern network-based thin clients, the failure of a single FC-9821KE can leave a control room blind to critical process variables. In a boiler-turbine-generator unit, for example, loss of HMI may prevent operators from responding to high drum level or turbine vibration alarms, increasing the risk of equipment damage or forced outage. Unlike modern systems, there is no web-based fallback—making this terminal a single point of operational vulnerability.

Reliability Analysis and Common Failure Modes

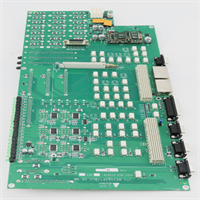

After 20+ years of continuous operation, the FC-9821KE suffers from predictable age-related failures. The most common issue is CRT degradation: dimming, focus drift, or complete tube failure due to cathode wear or high-voltage supply breakdown. The internal power supply—often containing electrolytic capacitors now well beyond their design life—is another frequent failure point, causing random reboots or inability to power on. Mechanical wear on the keyboard membrane or trackball can impair input responsiveness, while dust accumulation in the ventilation path leads to thermal throttling or motherboard overheating. Additionally, the proprietary NDX communication card (often integrated on the mainboard) is sensitive to electrical noise and may lose sync with the central controller if grounding deteriorates.

Recommended maintenance practices include:

- Performing quarterly CRT brightness and geometry calibration

- Replacing aging power supply capacitors proactively (capacitor plague mitigation)

- Cleaning internal air filters and heatsinks during scheduled outages

- Maintaining at least one fully functional spare unit powered periodically to prevent “storage death”

NEC FC-9821KE

Lifecycle Status and Migration Strategy

NEC exited the industrial automation market decades ago, and the FC-9821KE has been obsolete since the mid-2000s. No official support, firmware updates, or genuine spare parts are available from the manufacturer. Continued reliance on this hardware poses significant operational, safety, and compliance risks—especially as regulatory bodies increasingly require cybersecurity resilience and remote access capabilities absent in these legacy terminals.

Immediate risk mitigation includes:

- Acquiring and testing additional FC-9821KE units from decommissioned sites

- Implementing board-level repair programs for power supplies and CRT drivers

- Installing external video capture devices to enable temporary remote viewing (with security caveats)

For long-term sustainability, the only viable path is full migration to a modern DCS or virtualized HMI platform. While NEC offered no direct successor, facilities have successfully migrated to systems like Yokogawa CENTUM VP, Honeywell Experion, or open SCADA solutions using OPC DA bridges to emulate NDX data streams. Such projects require:

- Reverse-engineering of existing mimic diagrams and alarm databases

- Replacement of field I/O or integration via protocol gateways

- Recertification of operator workflows and safety procedures

Though complex, this transition eliminates dependency on irreplaceable hardware and restores operational agility—making it a strategic necessity for any facility planning continued operation beyond the next decade.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: