Description

Technical Specifications (For Spare Parts Verification)

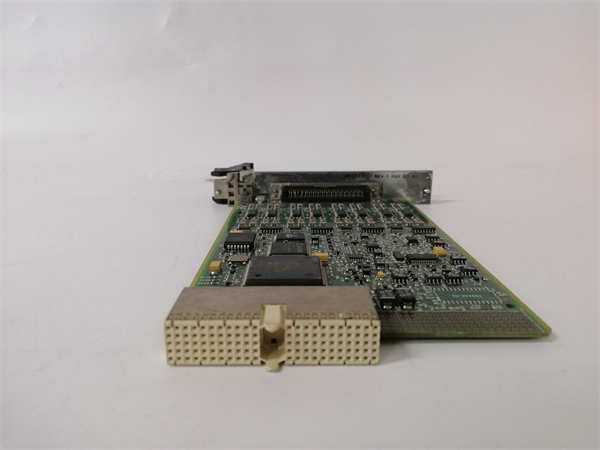

- Product Model: PXI-4351

- Manufacturer: National Instruments

- Platform: PXI (3U form factor, compatible with standard PXI chassis)

- Channels: 16 differential analog input channels

- Resolution: 24-bit delta-sigma ADC

- Sampling Rate: Up to 1.25 kS/s aggregate (software-configurable per channel)

- Sensor Support: Thermocouples (J, K, T, E, R, S, B, N), RTDs (Pt100, Pt1000, Ni120), thermistors, and ±10 V voltage inputs

- Cold-Junction Compensation: Integrated isothermal terminal block with ±0.3°C accuracy

- Excitation: Programmable current sources for RTD/thermistor biasing

- Isolation: 300 Vrms channel-to-chassis isolation

- Front-Panel Interface: Screw-terminal connector block (removable)

- Software Support: LabVIEW, NI-DAQmx, and legacy Measurement Studio environments

System Role and Downtime Impact

The PXI-4351 was a foundational component in temperature monitoring systems across aerospace test cells, pharmaceutical stability chambers, and power electronics thermal validation. Its integrated isothermal block eliminated the need for external cold-junction hardware, simplifying system architecture while ensuring metrological traceability. In regulated environments—such as ISO/IEC 17025 calibration labs—a failed or drifting PXI-4351 directly compromises measurement uncertainty budgets. A single channel offset error can trigger false alarms, cause batch rejections, or invalidate certification test reports. Because many installations rely on custom LabVIEW applications with hard-coded channel mappings, replacing the module demands exact functional and electrical equivalence to avoid extensive software revalidation.

Reliability Analysis and Common Failure Modes

Despite its robust design, the PXI-4351 exhibits predictable aging issues due to its analog-heavy architecture and thermal-sensitive components:

- Isothermal block sensor drift – the onboard temperature sensor for cold-junction compensation degrades over time, introducing systematic errors in thermocouple readings.

- Terminal block corrosion or loosening – repeated thermal cycling causes screw terminals to relax or oxidize, increasing contact resistance and measurement noise.

- Excitation current source instability – aging current references lead to RTD resistance miscalculation, especially at low temperatures.

- ADC reference voltage shift – long-term exposure to elevated ambient temperatures accelerates drift in the internal voltage reference.

The module provides no real-time diagnostics for sensor health or cold-junction integrity. Faults are typically discovered only during periodic calibration or when cross-checking against reference probes. Recommended preventive maintenance includes:

- Annual full-point calibration using NIST-traceable dry-well or ice-point references

- Torquing terminal screws to specification during routine inspections

- Verifying isothermal block temperature uniformity under no-load conditions

- Avoiding operation beyond 50°C ambient to prolong component life

PXI-4351 185450D-01

Lifecycle Status and Migration Strategy

National Instruments has formally discontinued the PXI-4351, with end-of-life announcements issued years ago. Factory repair, recalibration, and driver updates are no longer available. Continued use poses compliance risks in quality-managed environments where equipment must have valid, recent calibration from an accredited provider.

Short-term mitigation strategies include:

- Securing pre-qualified, calibrated spares from specialized legacy DAQ vendors

- Implementing redundant temperature monitoring (e.g., dual modules or external reference sensors) for critical zones

- Archiving original DAQmx task configurations and LabVIEW VIs in version-controlled repositories

For long-term sustainability, NI’s recommended replacement path is the PXIe-4353 or PXIe-4357, which offer:

- Higher channel counts (up to 32) and faster sampling

- Improved cold-junction accuracy (±0.1°C)

- Full compatibility with modern NI-DAQmx and LabVIEW NXG

Migration requires:

- A PXI Express chassis (not backward-compatible with legacy PXI)

- Rewiring to new terminal block layouts (screw-terminal vs. spring-clamp variants)

- Updating channel scaling and sensor type definitions in software

Given the centrality of accurate temperature data in safety, quality, and compliance workflows, organizations should classify the PXI-4351 as a high-risk obsolescence item. A proactive plan—combining inventory audit, risk-based prioritization, and staged migration—is essential to maintain data integrity and avoid operational disruption.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: