Description

Key Technical Specifications (For Spare Parts Verification)

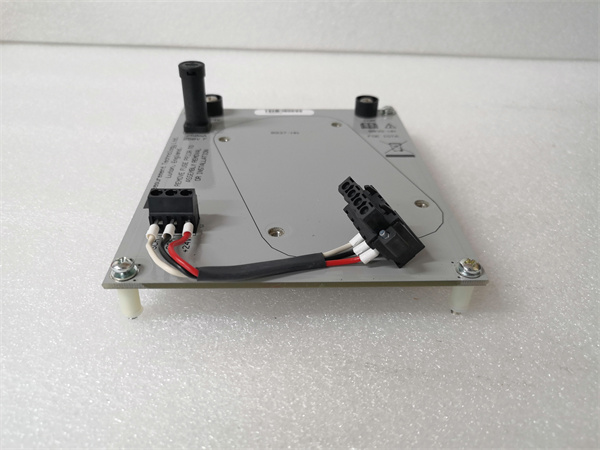

- Product Model: 8939-HN

- Manufacturer: MTL Instruments

- Series: MTL8000 series

- Function: 8-channel analog input isolator (unidirectional)

- Input/Output Signal: 4–20 mA DC (HART compatible)

- Isolation Voltage: 2.5 kV AC RMS between field, system, and channel groups

- Power Supply: 20–30 V DC via DIN rail bus or separate terminals

- Accuracy: ±0.1% of span at 25°C

- Bandwidth: >20 Hz per channel

- Mounting: Standard 35 mm DIN rail

- Housing Width: 22.5 mm (1 module width for 8 channels)

- Approvals: ATEX, IECEx, FM, CSA for use in hazardous areas (when installed per guidelines)

System Role and Impact of Failure

The MTL 8939-HN is typically deployed in the I/O marshalling cabinets of distributed control systems (DCS) or safety instrumented systems (SIS) in oil & gas, chemical, and power generation facilities. It serves as a critical barrier between field instruments (e.g., pressure, temperature, or flow transmitters in Zone 1/Class I Div 1 areas) and the control system’s analog input cards. Its primary functions are to provide galvanic isolation (preventing ground loops), enhance noise immunity, and enable safe operation in explosive atmospheres through intrinsic safety energy limitation.

If this module fails—due to power loss, internal component degradation, or channel drift—it can cause multiple process variables to read zero, full-scale, or erratic values. In a safety context, this may lead to nuisance trips or, more critically, failure to detect hazardous conditions (e.g., high pressure or level). Because one unit handles eight independent signals, a single point of failure can impact an entire skid or process section, potentially triggering a partial or full plant shutdown.

Reliability Analysis and Common Failure Modes

The MTL 8939-HN was engineered for high reliability, but units manufactured in the late 1990s to early 2000s are now well beyond their intended service life. The most prevalent failure mechanisms include aging of internal optocouplers and isolation transformers, leading to signal attenuation or complete channel dropout. Electrolytic capacitors in the DC/DC converter section are prone to drying out, causing output ripple or module reset under load. Additionally, repeated thermal cycling in hot control rooms accelerates solder joint fatigue, particularly at terminal blocks.

A key vulnerability is its passive HART support: while it passes HART digitally, any degradation in analog bandwidth or noise floor can corrupt the FSK signal, preventing handheld communicators or asset management systems from accessing field devices. For maintenance teams, recommended actions include periodic verification of channel accuracy using a calibrated current source, inspection of terminal tightness (loose connections cause heating), and monitoring for abnormal module temperature during operation. Given its dense 8-channel design, failure in one channel often precedes cascading issues—proactive replacement of suspect units is advised.

MTL 8939-HN

Lifecycle Status and Migration Strategy

MTL officially discontinued the 8939-HN as part of the legacy MTL8000 series phase-out. Eaton (current owner) no longer manufactures or supports this model, and factory repair services are unavailable. Continuing to operate with this module carries increasing risk: no warranty, no traceable calibration, and growing difficulty in sourcing functional spares.

Short-term mitigation includes securing tested spare units from reputable surplus suppliers or implementing channel redundancy where feasible. However, the sustainable path is migration to modern equivalents. Eaton recommends replacing the 8939-HN with the MTL8939-HN2 (if still available) or, more commonly, transitioning to the MTL5000 series, such as the MTL5939—a functionally equivalent 8-channel HART-transparent isolator with improved diagnostics, lower power consumption, and active product support. This upgrade typically requires only terminal re-wiring (same pinout in many cases) and does not necessitate changes to field devices or control logic. For sites with large inventories of MTL8000 modules, a cabinet-by-cabinet replacement plan during scheduled turnarounds offers a cost-effective route to restore long-term system integrity and supportability.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: