Description

Key Technical Specifications (for Spare Part Verification)

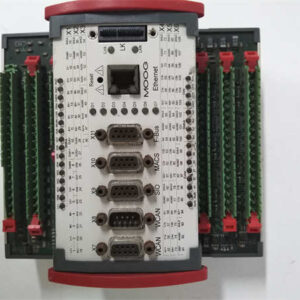

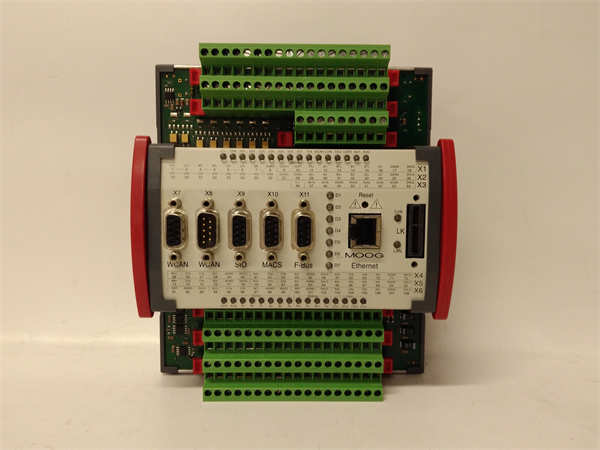

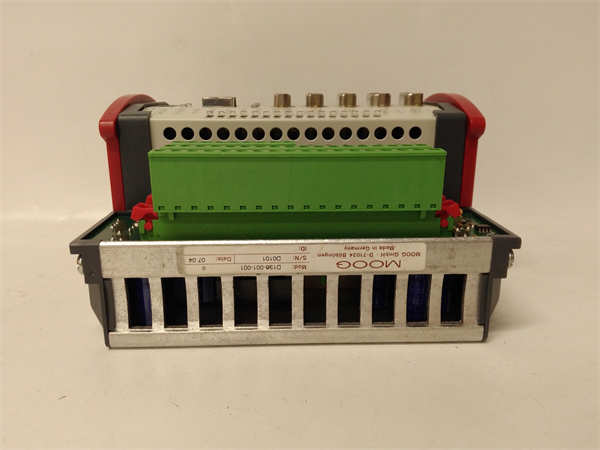

- Product Model: D136-001-001

- Manufacturer: Moog Inc.

- System Application: Typically used with Moog 761, 762, or D633/D634 series servo valves in power plant turbine bypass, fuel metering, or VIGV systems

- Input Signal: ±10 V DC command signal (from turbine controller such as GE Mark V or Westinghouse Q-Line)

- Output Current: ±80 mA typical (adjustable via internal potentiometers)

- Power Supply: ±15 V DC and +24 V DC (exact requirements depend on system integration)

- Feedback Type: Supports LVDT or internal position feedback (depending on valve configuration)

- Mounting Form: DIN-rail or panel-mount chassis-compatible module

- Diagnostic Features: Basic LED status indication (power, enable); no digital communication

- Calibration: Manual offset and gain adjustment via onboard potentiometers

System Role and Downtime Impact

The Moog D136-001-001 serves as the critical interface between a turbine or process controller and high-performance hydraulic servo valves. It converts a low-power analog command signal into a precisely controlled current that drives the torque motor of the valve, enabling millisecond-level response for pressure, flow, or position control. In combined-cycle or fossil power plants, it is commonly found in high-pressure steam bypass systems, where rapid valve actuation is essential during turbine trips to protect boiler integrity. A failure—such as output drift, loss of enable, or complete shutdown—can cause the servo valve to default to a safe position (often closed), leading to uncontrolled steam pressure buildup, forced derating, or emergency shutdown. Because these modules are often deployed in redundant pairs but not always hot-swappable, unplanned failure typically results in at least partial unit outage until a verified replacement is installed and re-calibrated.

Reliability Analysis and Common Failure Modes

Although designed for industrial environments, the D136-001-001 relies heavily on analog components that degrade over time. The most prevalent failure mode is drift in the output current due to aging operational amplifiers or reference voltage sources, causing valve positioning errors that manifest as control instability or oscillation. Electrolytic capacitors in the power supply section frequently dry out after 15–20 years of service, leading to ripple-induced noise or intermittent operation. The manual calibration potentiometers are another weak point—they can develop contact resistance or shift due to vibration, altering gain/offset without warning. Additionally, the module lacks overcurrent or short-circuit protection on the valve drive output, making it vulnerable to field wiring faults or valve coil failures. For maintenance teams, recommended practices include: performing annual bench calibration checks using a precision signal source and dummy load, inspecting for bulging capacitors or burnt components during outages, verifying enable logic integrity, and storing spares in climate-controlled conditions to minimize component aging.

-

MOOG D136-001-001

Lifecycle Status and Migration Strategy

Moog has officially discontinued the D136-001-001, with no direct new replacement offered. Support ended years ago, and original documentation is increasingly difficult to obtain. Continued reliance on this module introduces significant operational risk: secondary market units may be untested, misrepresented, or previously damaged; prices have risen sharply; and calibration expertise is becoming scarce. As an interim measure, facilities should maintain at least one fully tested spare per critical application and consider board-level repair by specialized electronics restoration vendors familiar with Moog analog circuits. For long-term reliability, Moog recommends migrating to modern digital servo valve controllers such as the Moog DCS (Digital Control System) platform or Integrated Servo Valve (ISV) solutions, which offer built-in diagnostics, Ethernet connectivity, and auto-calibration. This migration typically requires replacing both the amplifier and the servo valve assembly, along with updates to the host control system’s I/O and control logic. Alternatively, third-party retrofit kits (e.g., from Bosch Rexroth or Parker) can provide drop-in digital replacements with analog command compatibility, reducing integration effort while extending system life. Early planning is essential—migration projects often require outage windows and engineering validation to ensure safety and performance equivalence.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: