Description

Key Technical Specifications (For Spare Parts Verification)

- Product Model: MODHUB-16E

- Manufacturer: Contemporary Controls

- System Family: Modbus Integration Gateways

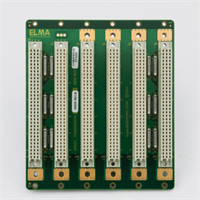

- Serial Ports: 16 independent isolated RS-485 half-duplex ports

- Ethernet Interface: 10/100 Mbps RJ-45 with auto-MDI/MDIX

- Supported Protocols: Modbus RTU, Modbus ASCII over serial; Modbus TCP/IP over Ethernet

- Power Input: 24 VDC (terminal block), typical consumption ~10 W

- Isolation: 2500 Vrms port-to-port and port-to-Ethernet

- Configuration Method: Web-based interface or Windows utility (MODHUB Manager)

- Firmware Version: Typically v2.x or v3.x (critical for compatibility)

- Physical Form: DIN-rail mountable, metal enclosure with status LEDs per port

- Operating Temperature: 0°C to +60°C

System Role and Downtime Impact

The MODHUB-16E was widely deployed in the 2000s and early 2010s as a cost-effective solution to connect large clusters of Modbus-enabled field devices—such as energy meters, motor controllers, and remote I/O—to Ethernet-based SCADA or BMS platforms. A single unit often aggregates data from an entire substation, pump station, or HVAC zone. It resides in control panels near serial device clusters, acting as the sole communication conduit to the central server.

If this gateway fails, all 16 connected serial devices become unreachable. In a water treatment plant, this could mean loss of flow, level, and chemical dosing data across multiple basins. In a commercial building, it might disable chiller sequencing or electrical submetering. Because these systems rarely include redundant gateways, failure typically forces operators into manual checks or local control, increasing labor costs and risk of oversight. Recovery requires physical replacement and reconfiguration—a process that can take hours if backup settings are unavailable.

Reliability Analysis and Common Failure Modes

Despite its rugged design, the MODHUB-16E is prone to age-related failures due to its dense electronics and continuous operation. The most frequent issues include:

- Power supply capacitor degradation: Electrolytic capacitors on the internal 24 VDC converter dry out, causing voltage sag, spontaneous reboots, or complete power failure—especially in high-temperature enclosures.

- Firmware corruption: Flash memory errors (often triggered by power cycling without clean shutdown) render the unit unresponsive or stuck in boot loop.

- RS-485 transceiver burnout: Repeated ground loops or lightning-induced surges on field wiring damage the isolated transceivers, disabling one or more ports.

- Ethernet PHY failure: The physical layer chip overheats over time, leading to intermittent network drops or total Ethernet loss.

A critical vulnerability is configuration dependency: settings (IP address, serial parameters, Modbus mapping) are stored in volatile flash memory. If lost, restoring service requires access to archived configuration files—often missing in older installations.

Recommended preventive actions:

- Maintain a backup of the gateway’s configuration (.cfg file) using MODHUB Manager.

- Install external surge protection on all RS-485 lines.

- Ensure adequate panel ventilation to keep ambient temperature below 50°C.

- Test spare units by loading the production config and verifying multi-port communication under load.

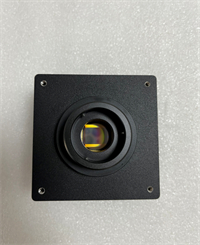

MODHUB-16E CONTEMPORARY

Lifecycle Status and Migration Strategy

Contemporary Controls discontinued the MODHUB-16E and replaced it with more secure, higher-performance gateways such as the BASM-ETH (for BAS) and IQ+ series (for industrial use). Official firmware updates and technical support ended years ago.

Continued use poses significant cybersecurity and reliability risks: the MODHUB-16E lacks modern features like TLS, user authentication, or SNMPv3, making it non-compliant with current OT security policies. Spares are scarce, and used units may harbor hidden hardware faults.

Short-term mitigation:

- Source and fully validate surplus MODHUB-16E units, including firmware reload and 72-hour burn-in testing.

- Isolate the device on a VLAN with strict firewall rules to reduce exposure.

Long-term migration path:

- Replace with the Contemporary Controls BASM-ETH or IQ3000-16S, which offer:

- Same 16-port RS-485 capability

- Enhanced security (HTTPS, SSH, RADIUS)

- Built-in data logging and OPC UA support

- Backward-compatible Modbus mapping tools

Migration requires:

- Re-cabling (if terminal block layout differs)

- IP readdressing

- Updating SCADA driver configurations

However, it restores vendor support, improves resilience, and aligns the system with modern operational technology standards. For facilities managing dozens of legacy gateways, a staged replacement program—prioritizing units in critical or exposed locations—is the most sustainable approach.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: