Description

Technical Specifications (For Spare Parts Verification)

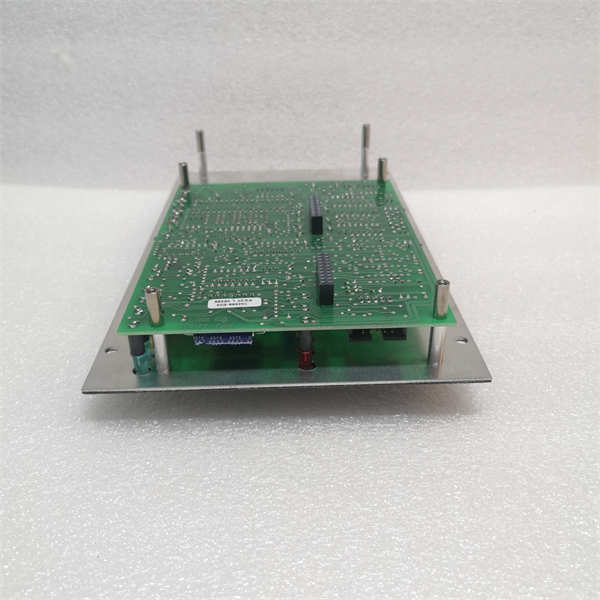

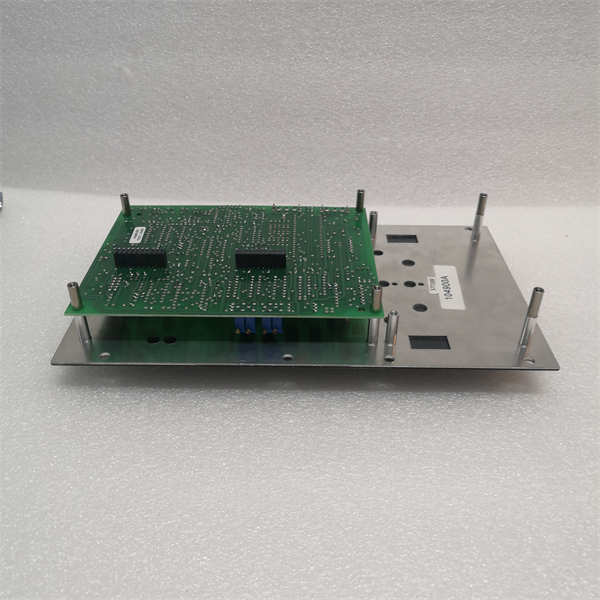

- Product Model: 104988-E03

- Manufacturer: Microset S.p.A.

- Product Family: Custom Control Stations / Modular Operator Interfaces

- Typical Construction: Polycarbonate or aluminum enclosure, front-mounted components (e.g., 22 mm pushbuttons, key switches, pilot lights)

- Electrical Rating: Likely 230 V AC / 24 V DC control circuits, rated per IEC 60947

- Environmental Rating: Possibly IP65 or IP66 (common for outdoor energy applications)

- Mounting: Wall-mounted or panel-integrated, with cable gland entries

- Certification: May include CE, EN 50121 (railway EMC), or IEC 61850 compliance depending on application

- Markings: Labeling typically includes circuit function (e.g., “Circuit Breaker Open/Close”), not just part number

System Role and Downtime Impact

In critical infrastructure—such as electrical transmission substations or railway traction supply—the 104988-E03 often provides local manual control when SCADA or remote systems fail. For example, it might allow operators to manually trip a circuit breaker, reset a protection relay, or switch between redundant power feeds.

If this panel fails (e.g., due to contact welding, seal degradation, or internal wiring fault), the site may lose all local intervention capability, forcing reliance on remote commands that may be unavailable during communication outages. In worst cases, this could delay response to faults, increase arc-flash risk during maintenance, or violate regulatory requirements for manual override (e.g., IEEE C37.2 or EN 50124).

Replacement typically requires de-energizing high-voltage equipment and coordinating outages—making lead time and spare availability mission-critical.

Reliability Analysis and Common Failure Modes

Common failure modes stem from harsh environmental exposure and infrequent operation:

- Contact oxidation or sulfidation in pushbuttons/switches due to humidity or industrial pollutants, leading to high resistance or open circuits

- Gasket hardening or UV degradation of polycarbonate enclosures, compromising IP rating and allowing moisture ingress

- Internal wiring fatigue at terminal blocks from thermal cycling, especially in outdoor cabinets with wide temperature swings

- Label fading or delamination, causing operational ambiguity during emergencies

Preventive measures include:

- Annual functional testing of all switches under load

- Inspection of seals and drainage vents

- Application of contact lubricant (e.g., DeoxIT) during maintenance outages

- Photographic and schematic documentation of existing units before failure

MICROSET 104988-E03

Lifecycle Status and Migration Strategy

Microset remains active and generally supports legacy products, but custom assemblies like 104988-E03 are not guaranteed. The company may offer a functional equivalent using current modular components (e.g., from their MCS or MCI series), but this requires re-engineering the panel layout, updating wiring diagrams, and re-certifying for safety.

Recommended actions:

- Immediately document the existing unit: take photos, record switch types (e.g., Microset code 1S1B2R), note terminal wiring, and archive any labels.

- Contact Microset directly with the full part number and, if possible, the original project reference—request a “like-for-like” rebuild or modern equivalent.

- Consider panel retrofit: Replace the entire assembly with a standardized Microset modular station (e.g., MCS-22 series) using current catalog parts, ensuring backward-compatible functionality.

- Implement redundancy: For critical sites, install a secondary manual control path or upgrade to a small local HMI with hardwired backup.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: